A comment

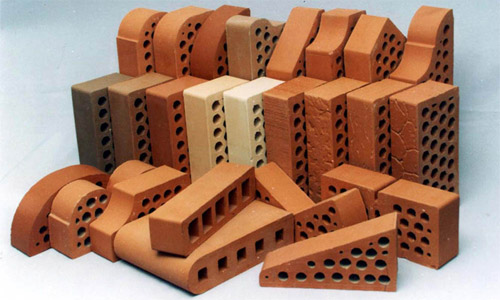

For many years of work at construction sites, I can recall several cases when ceramic brick presented unpleasant surprises:

1. In the production of face masonry in winter, some antifrosty additives in the mortar (potash, urea) are absorbed by the brick, after which they appear on the facade in the form of efflorescences, which are not easy to clean later;

2. Relief masonry, very beloved by architects (this is when individual fragments protrude from the plane of the wall), often causes atmospheric moisture to get into the voids of the brick. In winter, water naturally tears the front layer;

3. Now, most of the ceramic bricks are made in Euro standards, on imported production lines. It is of high quality, but expensive. Wanting to save money, the developer often turns to cheap clinker brick, which is done the old fashioned way and burned with coal. In the 90s, I had such a plant and, getting this brick, the builder should pay attention to its color:

• The highest quality brick, made with the addition of blue, pottery clay, has a bright red-brown color;

• The predominance of brown, should tell the builder that the brick is unfinished. Accordingly, it has low strength and frost resistance;

• Bluish tones - this is a burn, which leads to deformation and cracking of bricks;

• The yellowness of the brick indicates that there is not enough clay in its composition, without which its characteristics may not correspond to those indicated in the product certificate.

Honored Builder of Russia S. Mironenko