Types of facing bricks by manufacturing material, colors, texture and shapes

Facing bricks are outwardly more attractive than ordinary ones - after all, it is an element of wall decoration and should not “hit the face with dirt”. It is used not only for cladding, but also for the manufacture of beautiful fences, and in some cases for interior decoration. As you can see in the photos below, the types and colors of facing bricks are significantly different. And what exactly - read on.

Content:

Types of facing bricks, depending on the material of manufacture

The main ingredients used in brick production are cement with limestone and clay. For staining, substances of natural origin are used. It turns out material that is resistant to severe frost, does not allow water and is environmentally friendly. Depending on the production technology and the ingredients used, the facing brick can be: ceramic, clinker, hyper-pressed and silicate.

Ceramic brick

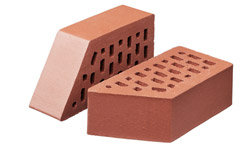

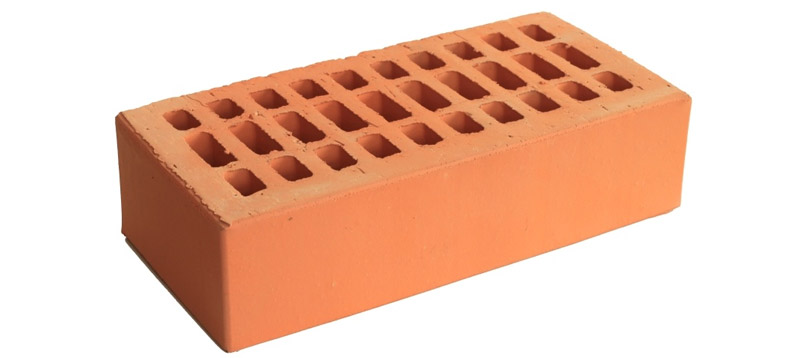

This type of facing material can be solid or hollow. This brick is made from certain grades of clay. This does not affect the appearance, but the load on the supporting structures (directly dependent on the severity of the materials) is different - this should be taken into account when buying a brick.

As for the front surface, it is decorated in many ways. The classic option is a smooth plane (shiny or matte). A textured finish imitating a completely different material (for example, stone) is possible. A popular finish is glazing, giving the surface an elegant look and a beautiful sheen. A great option for making mosaics.

Ceramic hollow facing brick.

Brick brick

This type of product also refers to ceramics, but is a more modern variation of it. Thanks to additives of a special grade of clay and firing at a very high temperature, a very strong and durable material is obtained. It is useful where the loads are large and constant. With clinker products, it is good to arrange the openings of windows with doors, pave the paths in the country house or the yard, and trim the basement.

Since the brick has a high density and a minimum of pores, its water absorption is very low. This fact increases resistance to frost. The lined plane can serve for a long time, without being covered by cracks and chips and without losing its beautiful appearance. But in the increased density there is a small catch - an increase in thermal conductivity.

A wide variety of different colors palette of clinker stones, as well as its overall characteristics. For example, there is a species called the “long brick”, the length of which is really solid - 52.8 centimeters. Its width and height are 10.8 and 3.7 centimeters.

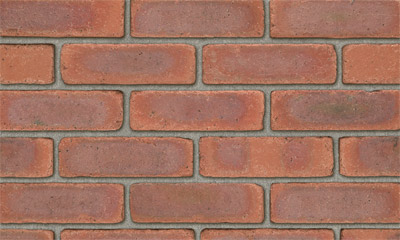

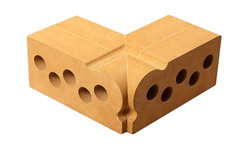

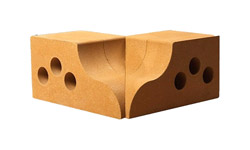

Clinker hollow facing brick.

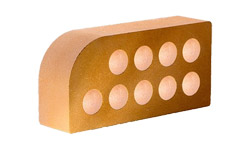

Hyper pressed brick

This type of product is obtained without the use of firing. Instead, it uses the high pressure method, acting with its help on molded products. Components such as sand and clay are excluded from this brick. It uses limestone, cement additives and special dyes.

Thanks to technology, the brick has a very textured chip, similar to the appearance of a natural stone surface. This is often beaten by artists, designers, as a result of a very original building. In addition, this type of brick is easy to process, while its properties are preserved.

Hyperpressed products have increased strength, are not afraid of severe frosts, and their shape is just perfect (there are no bumps or deviations from right angles).However, the thermal conductivity is quite high (because it depends on the density). Here is perhaps the only drawback. However, it is easily corrected by using a heat insulator.

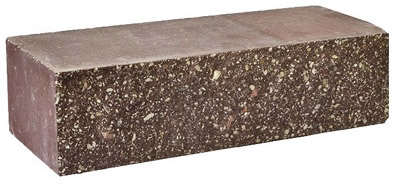

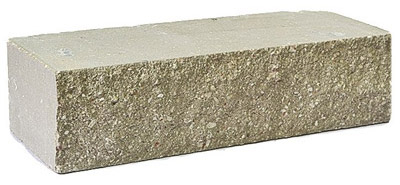

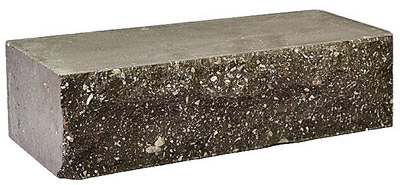

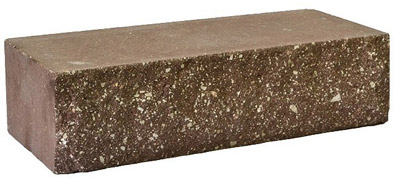

Hyper pressed brick.

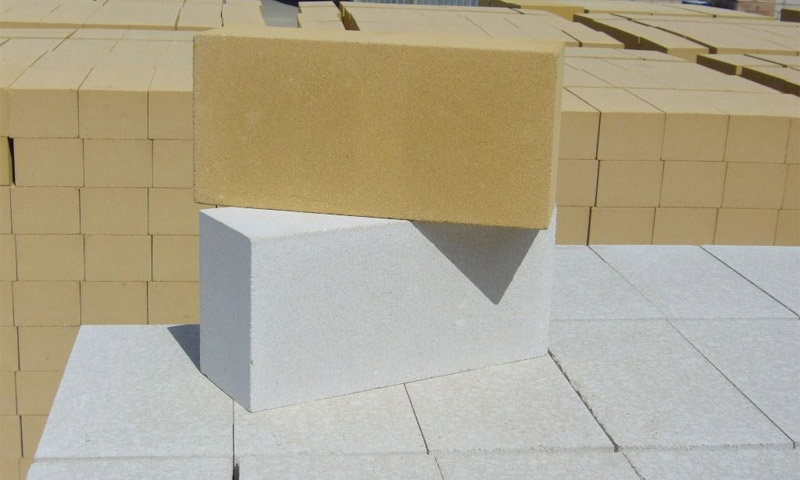

Silicate brick

This variety will cost the least, however, in terms of external characteristics, it is one of the last places. Therefore, silicate products are used less and less for facing. People want to see the walls of their houses decorated beautifully and tastefully, and other materials make it better than silicate brick.

Solid silicate brick.

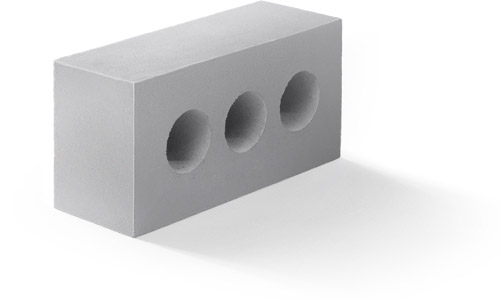

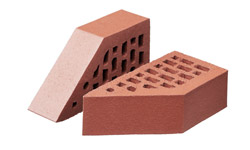

Hollow and corpulent facing brick

Bricks for facades can be monolithic (solid), filled with material throughout the volume and have a solid weight. They make a stronger lining (but also colder).

Hollow are products with internal cavities (round, square, rectangular). Such a brick is lightweight and retains heat better by keeping it inside voids.

Types of colors of facing bricks

When choosing a shade for decorating the facade of the house, they look at what gamut windows, doors, roof and other elements have. The choice of color also depends on the dimensions and shape of the building.

So, if the lining area is small, then the eye is able to see fewer color tones of the brick. Many of them seem fainter and paler than they actually are. Therefore, when making small details, choose brighter colors, more often, so that they play as they should.

If you want to see in all its glory some not very bright or darkish tone, then use a sufficient area. Suppose, lay out the entire large wall with such a brick. Keep in mind that very dark colors are often perceived as solid black.

In addition, remember the combination of colors when they are nearby. Together they look different than alone. If their brightness is approximately equal, then they can change tones (in the masonry of the Bavarian type, this is important). This effect is especially noticeable when framing one color with another. But on the border, the opposite is noticeable: the colors acquire a saturated edge (dark - dark, light - light), as if trying to fence off each other.

Colors of front ceramic and clinker ceramic bricks

The gamut of colors for these products is vast, but even one color can vary in shades in batches. After all, the resulting color depends on firing, as well as on the presence of certain impurities (usually metallic). For example, iron gives redness. The larger it is, the brighter the brick.

And if the lining is carried out, taking turns using products from different lots, then on the walls not very aesthetic multi-colored groups of bricks can be obtained. Experienced masons, however, figured out how to deal with this: they take bricks from one party, now from another, then from a third. As a result, the wall comes out uniform in color - the color differences are small and not striking.

And a number of manufacturers also decided to help consumers by producing packs of bricks, the color of which is different. Even more than that - sometimes even the surface of individual parts has smooth transitions of shades. All of the above features are the norm for this type of brick.

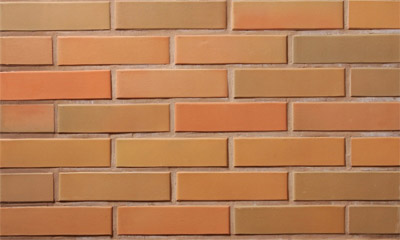

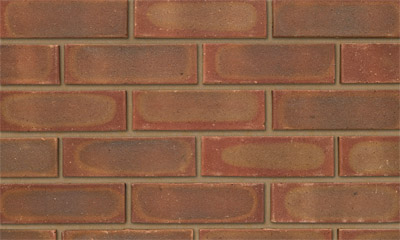

So that you can appreciate all the color features of ceramic facing bricks, below we provide photos not of individual bricks, but masonry of certain colors of ceramic bricks:

Hyperpressed Brick Colors

There is no firing, so the coloring pigment added to the molding mass sets the tone for the products. Due to this fact, all the bricks are painted exactly throughout the volume, and the parties do not differ in scale from each other. However, the added cement with its dirty gray color reduces the brightness of the products.They can always be distinguished from clinker and ceramic bricks by a slightly grayish tint - the so-called "concrete".

Photo of facing hyper-pressed brick and its color:

Colors of silicate facing brick

The easiest way is to paint such a brick throughout the mass, for which dye is added to the capacity of the mixer, where the mixture is prepared. To measure the right amount of paint, use a dispenser. It is important not to overdo it: too much paint is expensive and can lead to deterioration in strength. And if you put a little dye, then the products will turn pale and ugly. Sometimes, in order to save money, only the front layer on both sides is painted.

The main colors in which the silicate brick is painted are presented below:

Front Types

To diversify the types of facing bricks helps design its relief or texture. In this case, roughnesses, depressions or depressions forming a pattern are made on a spoon (poke). It can be ordered or randomly applied. To obtain it, several methods are used.

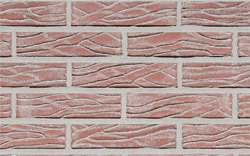

The texture on ceramic and clinker bricks

In those bricks in the production of which firing is used, the relief is easier to create: the wet patterns are applied to the wet molded products, then dried and sent to the oven until completely hardened. This application method does not damage the surface, so that the corrugated bricks remain as strong as smooth.

Their varieties are very impressive and it is not possible to show all the samples within the framework of this material, but you can see some of the most interesting textures below:

In addition, other methods of creating textures are used.

Shotcrete. With this method, crumbs of mineral origin are applied to the face of the products — they do this before firing. By soldering crumbs with a brick surface, an original texture is formed. And the combination of different colors allows the product to sparkle with new colors that smoothly transition into each other.

Note that a high temperature is required here (in order to melt the mineral particles and sinter them with the surface), so only clinker bricks are shotcreted. The resulting decorative products can be beautifully finished with columns, corners of the mansion, windows with doors.

However, the relief is worse in care than a smooth plane. A shotcrete brick collects even more dirt. And if it is white or light cream, you will have to clean it often enough, making a lot of effort.

Ceramic brick shotcrete with mineral chips.

Shotcrete masonry.

Engobing - ceramic coating. It uses a liquid ceramic mass (engobe). It is applied by watering or sprayed on the surface (already well-dried), completely covering the color and texture of the products. Then follows the burning in the oven. As a result, the brick acquires a ceramic coating with a thickness of about one millimeter.

Sometimes, in order to achieve a certain effect (for example, the illusion of old brickwork), the engobe does not cover the entire front surface, but only certain sections. So interesting color transitions turn out.

As for operational properties, they are about the same as other types of bricks. However, you should not forget that the finish layer is quite thin, so you need to act carefully so as not to accidentally scratch and chip it.

Some types of engobing are presented below:

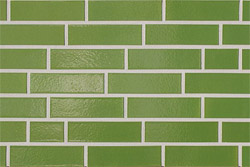

Glaze coating. This technique is very close to the previous one. But here, for decoration, not a clay-based mixture is used, but a glaze of a special composition. It is much stronger and more decorative.In addition, such a surface, resembling a glass, acquires protection against moisture. Here you can experiment with might and main with shades and drawings - glazing is quite possible. Mandatory firing - without it, the finish will not harden.

Examples of glazed ceramic bricks:

The texture for hyperpressed bricks

Since high temperatures are not used in the manufacture of these products, they act in a different way to impart relief than in all the methods described above. To do this, they began to use the method of splitting bricks, getting products that look like natural stone. Visually, it looks about the same as a chip on a broken piece of rock. By betraying brick to various chips, manufacturers produce entire product lines with certain textures. The same manufacturers began to give their names to the manufactured textures, so hyperpressed bricks can be found on the market, which seem to have the same chip, but different names.

The split is made using special equipment. This equipment is a kind of guillotine that splits bricks in the desired plane, resulting in a texture called chipped. To give a brick, for example, a texture called "torn brick", a chipped or even flat billet, along the perimeter of the front surface, is subjected to additional chips with a special machine. Thus, plucking the blanks for various treatments, the following textures of hyper-pressed bricks are produced: chipped, ragged, rock, wild stone, marble, Finnish.

Silicate brick texture

Silicate brick cannot boast of such a variety of textures. However, modern technologies make it possible to create a rusted and chipped texture on the front surface of this brick.

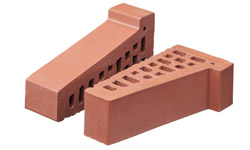

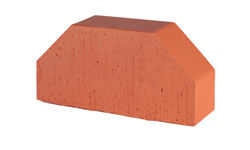

Varieties of facing brick forms

It is through cladding that you can magically transform a house, which is an ordinary rectangular "box". Having done something exclusive, original and impressive. And to make it easier to cope with this task, manufacturers produce a special facade brick - figured. With it, even to lay out a complex pattern is not a problem.

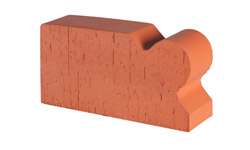

Curly Ceramic Bricks

Such products beautifully make out the space around doors with windows, process corners, cornices, and lining columns. Usually the front side and sides differ from the standard form. Next, we describe the main varieties.

4. A slice at 45 degrees is designed so that the brick takes the form of a trapezoid with an upper side of 12.5 centimeters.

5. The product is beveled 9 degrees in length and has a rounding of one corner with a radius of 30 millimeters. In addition to the standard length of 24 centimeters, it can have a length of 28 centimeters.

11. Brick for cladding, having sections at 45 degrees from two sides. The heads remain 5.5 centimeters.

17. A brick in which one corner has a concave rounding. Its radius is 5.5 centimeters. There remains a head height of 6 centimeters.

Almost all popular forms of ceramic bricks are provided above, but depending on the manufacturer, they may have differences.

Hyper Pressed Figured Brick

Hyperpressed brick also boasts a huge variety of shapes.

About the size of the facing brick

Most often, single-sized bricks are used. Their long part has a size of 25 cm, and the other two sizes are 12 and 6.5 cm. One and a half bricks are thicker - instead of 6.5 centimeters, this parameter is 8.8 cm for them. There are also double products in which the thickness reaches 13.8 cm. This is all domestic measurements.

If we talk about European standards, then they mainly use bricks of slightly different dimensions: 24 cm. Length, 11.5 cm. Width and 7.1 cm. Thickness.

The Americans also have their own way: 25 by 6 by 6.5 cm. Or 24 by 6 by 7.1 cm. (The last option refers to clinker, it is often done in Europe using the German NF standards).