18 best welding machines - an overview of models and types of equipment

Welding allows you to firmly connect different types of metals. For its implementation, several types of power sources have been developed. There are welding methods: TIG, MMA, MIG / MAG. In this review, we will give tips on choosing equipment depending on the nature of the work and consider the rating of welding machines, compiled taking into account reviews and key parameters. This will help determine the type of machine for welding and choose a model with suitable characteristics.

The selection of goods was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.

Which welding machine is better to choose

Which welding machine is best depends on the amount of work ahead, future operating conditions, the thickness and type of steel to be welded. Consider the types of equipment by type and ability, which will help narrow down the search for goods.

How to determine the type of power source of the welding machine

The main role in the process of welding metals is played by the source that generates the welding current. The characteristics of the CVC and the ability to connect certain types of steel depend on this.

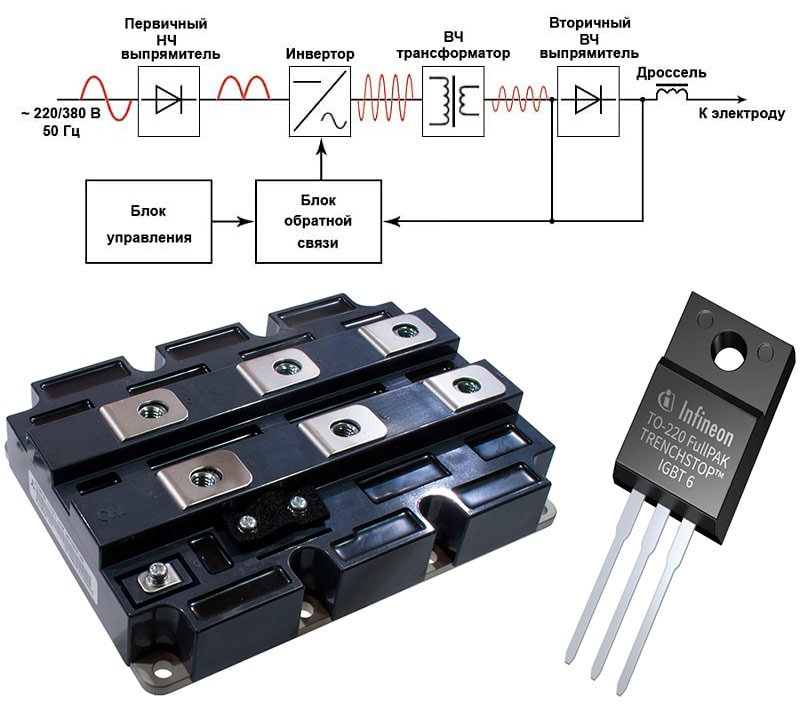

Inverter

A new generation of welding machines built on transistors. The equipment absorbs alternating voltage with a classical frequency of 50-60 Hz, converts it through a diode bridge into direct current, then returns it again to alternating, but with an increased frequency of 100 kHz. Then the amplitude of the volt decreases to 50-80 to create a safe voltage, and the amperes, on the contrary, increase to 140-400. At the last stage, the current becomes constant again.

Such equipment can be domestic and professional. It is connected to the network both 220 and 380 V. The range of current strength allows you to weld a thickness from 1.0 to 20.0 mm (depends on the maximum ampere rating). Constant tension provides even, smooth joints with increased strength. Due to the transistor conversion technology, inverters are distinguished by low weight and dimensions. Devices for manual arc welding, argon or semiautomatic devices can work on the basis of the inverter. Devices with AC / DC mode are suitable for welding aluminum.

The scheme of the welding inverter.

Currently, at home, it is advisable to use these types of power sources.

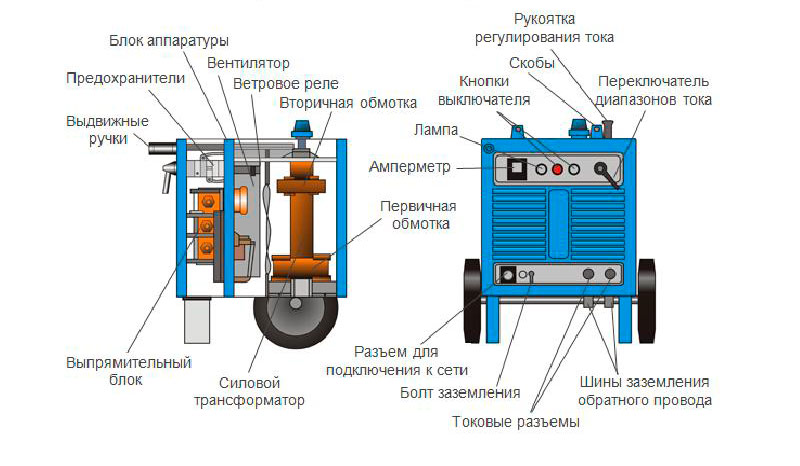

Rectifier

The equipment was named for its function - rectification of current from alternating to constant. For this, coils and diode bridges are used. Unlike inverters, there is no increase in frequency. The lack of transistors affected the increased dimensions of the models. They are connected mainly to 380 V. The devices are more suitable for industries and enterprises. Direct current allows you to perfectly weld both ferrous metals and stainless steel. Most often, rectifiers are used for manual arc welding.

Welding rectifier device.

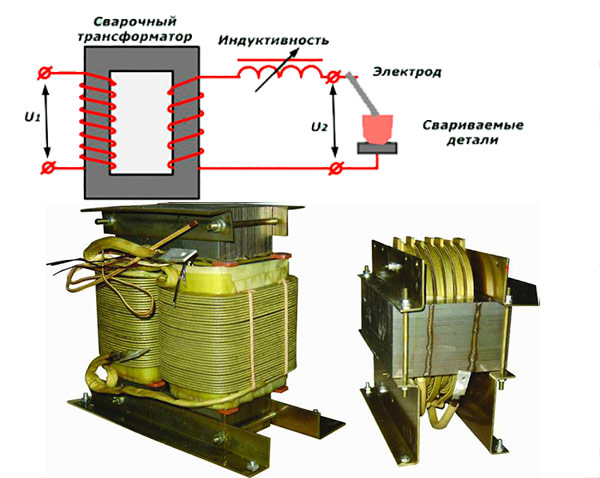

Transformer

The transformer simply lowers the volts to a safe value (50-70 V), and raises the amperes to melt the edges of the metal.This is due to the presence of two windings operating on the principle of magnetic induction. But the technology is distinguished by the large size of the equipment. Transformers are cooked only on alternating current, therefore they are suitable for non-critical structures. There are domestic and industrial models. Used only for manual arc welding.

Welding transformer device.

How to determine the type of welding machine

As we have already indicated above, several types of welding machines are created on the basis of the inverter that are capable of performing different processes. Which type to give preference depends on the upcoming welding tasks.

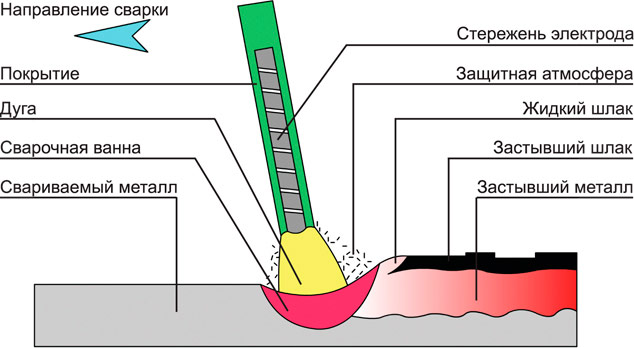

MMA welding machines - manual arc welding

Such equipment will only be able to weld ferrous metals. Welding is carried out by the holder and a coated consumable electrode. Seams need to be cleaned from slag, and a constantly burning electrode must be brought to the surface (to maintain an arc length of 3-5 mm) and changed after completion.

Scheme of the manual arc welding process.

The equipment stands out at an affordable price. MMA devices are suitable for a summer residence, a garage, a small workshop, where only low-carbon steel is welded.

Welding machine for manual arc welding.

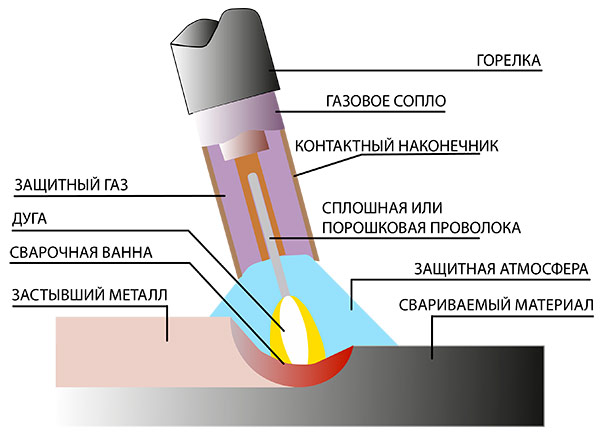

MIG / MAG welding machines - semi-automatic shielded gas welding

By this name is meant equipment for semi-automatic welding in a gas environment. The letter I means the use of an inert gas, and the letter A means active. In practice, it is argon or carbon dioxide, less often helium is used. Gas protects the weld pool from the influence of ambient air (prevents the appearance of pores). Semi-automatic welding contains a special mechanism for feeding wire to the torch. The welder only needs to press the button and lead the seam. At the same time, gas purging is started. Seams do not need to be cleaned, the connection is strong and can be uninterrupted.

Scheme of the process of semi-automatic welding.

Semi-automatic welding is advantageous for its high speed of work and an aesthetic appearance of joints. But the equipment is more expensive than devices for MMA. Such models are actively used in car body repair and at various enterprises. Depending on the type of wire installed, ferrous metals, stainless steel and even aluminum can be welded.

Welding machine for semi-automatic welding.

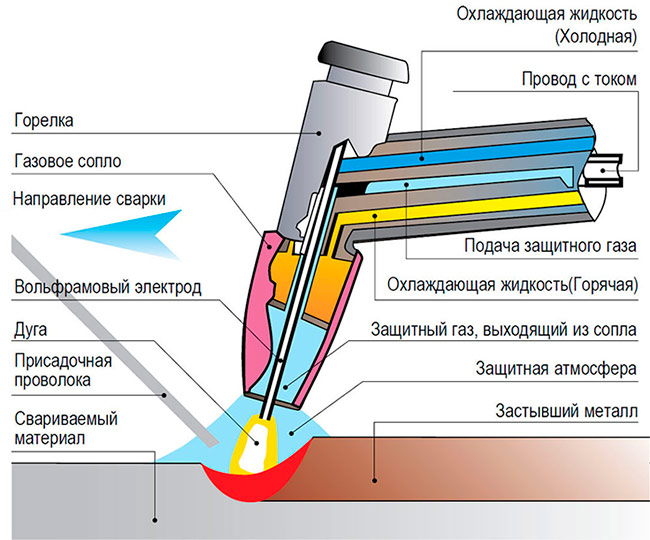

TIG welding machines

Method means welding in an argon atmosphere, where an arc burns between the product and a non-consumable tungsten electrode. The latter does not change the length, which means the arc burns steadily and it is easier for the welder to control it. The seam is not covered by slag and does not need subsequent cleaning. With the help of TIG machines, carbon and stainless steel, copper, aluminum and other metals can be welded.

Scheme of the argon arc welding process.

There are industrial and domestic installations. The devices are suitable where thin but strong seams are needed (manufacturing of towel dryers, collectors, filters for industrial water treatment, in the food and chemical industries). For welding, you will need a cylinder with argon or helium, as well as a gearbox.

Universal welding machines

Universal welding machines have been developed that combine several or all of the above modes at once. If you need to alternate welding for a building site (channel, corners) with periodic body repair, then it is practical to buy a MMA + MIG welding machine. When there is a need to periodically weld aluminum (engine block, oil pan), then select an inverter with MMA + TIG modes. To make your device ready for any tasks, buy MMA + MIG + TIG.

Universal welding machine.

The best welding machines for manual arc welding MMA

Having examined the types of power sources and types of equipment, we will move on to the product rating, which will help you choose the best welding machine for working with coated electrodes. Here are seven models with good specs and positive reviews.

RESANTA SAI-190

The head of the rating of welding machines for MMA is domestic product from the Resanta brand. The SAI-190 model produces a maximum welding current of 190 A. At the same time, the device creates a load of 5.5 kW on the network, so it can work from a conventional household outlet.On the front panel there is an amp controller without a display. Continuously, the apparatus can be cooked for 7 minutes, after which a 3-minute pause is required.

+ Pros RESAI SAI-190 advantages

- Robust powder coated metal housing.

- There is an indication of the network and the inoperative plug.

- Convenient shoulder strap.

- Useful functions for beginners ("Anti-stick" and "Hot start").

- High idle 85 V for easy ignition of the electrode.

- Weighs 4.7 kg.

- Protection of the network cable at the entry point from kinks.

- Cons RESAUT SAI-190

- There is no screen.

- Drawn scale for approximate amp settings.

- There is no hard carry handle.

- Short welding cable.

- There are no copper plates on the clothespin.

- Warranty seal disappears - need to be sealed.

Conclusion. This welding machine is the best for giving. It is unpretentious to mains voltage and can function from 140-260 V. If you have a weak power line in the village, then the inverter can cook a "three". With good voltage, it is possible to confidently run the seam with the “four”.

Svarog REAL ARC 200

In second place is the welding machine for MMA - Svarog Real. The model has a welding current range of 10-200 A. The ampere adjustment wheel is rubberized and it is convenient to handle it with working gloves. Rigid handle makes moving equipment easier. When connected to a network, it consumes 7 kW of power. PV at "maximum speed" is allowed up to 60%. The product is characterized by compact dimensions of 31x13x26 cm. It can be used outdoors in frosts down to -10 degrees.

+ Pros Svarog REAL ARC 200

- Low cost.

- Light weight 4.6 kg is convenient for frequent transportation.

- A 5-year warranty is maintained, even if annual service is not required.

- It cooks very well at 180 A.

- A simple model with high maintainability.

- Overheating does not work even when the housing is heavily dusted at a construction site.

- Deep penetration of metal.

- Cons Svarog REAL ARC 200

- Includes wires with a cross section of 16 mm².

- Weak electrode holder - consumable dangles.

- When working for the first time there is a smell of plastic.

- There is no instruction in the box.

- Wires tan and break at low temperatures.

Conclusion. This is the best option when you often need to rearrange the device at the workplace (welding pipes, fittings, welding farms to mortgages, etc.). Please note that all corners of the body are covered with rubber pads. This protects the equipment from damage during impacts, and also increases the safety of the welder carrying the apparatus.

Fubag IR 200

In third place are products from a German manufacturer. The welding machine is available in a completely iron case and is equipped with perforations on four sides for accelerated cooling. The maximum welding current is 200 A, and the PV in this case is 40%. The kit comes with a 2.8 m network cable, as well as a ground cable (1.6 m) and a holder cable (2 m). Despite the household class of the device, it has a screen with indication of amperes.

+ Pros of the Fubag IR 200

- Weighs 4.6 kg.

- The arc burns continuously and softly.

- The electrode on rusty metal is easily heated (you don’t even need to knock, just touch it).

- The device confidently cooks at low voltage up to 150

- There are three additional features that simplify welding.

- The display makes it easy to control settings.

- The cooler rotates quietly.

- Cons Fubag IR 200

- Short network wire.

- The model has no legs - it stands with the case directly on the ground.

- Heats up when welding "three".

- Frequent breaks are needed - PV40%.

- The power button on the back - it is inconvenient to stretch when working on the table.

Conclusion. We note this welding machine as the best for high-altitude work. It has compact dimensions of 34x12x24 cm and weighs 4.6 kg. The kit already has a shoulder strap. The controls are protected by the visor of the top cover, so they won’t get knocked down by touching your clothes. With it, it will be easy to assemble the frame of the gazebo, greenhouses or fix the antenna mast.

Eurolux IWM-190

This is a relatively inexpensive welding machine for MMA, which looks like a toy, but perfectly cooks with 3 mm diameter electrodes. The manufacturer even equipped it with the functions "Hot start" and "Anti-stick".The inverter generates a direct current and operates on an input voltage of 160-260 V. A switch-on duration of 70% is declared. The housing has numerous perforations for cooling. Inside, several 50 A diodes are used to build the circuit. The range of adjustment of the welding current is 5-190 A.

+ Pros of Eurolux IWM-190

- Metal case.

- Embossed on the adjustment wheel to easily grasp even in gaiters.

- Operation at a temperature of -10 ... + 40 degrees is allowed.

- Electrodes are easily ignited due to idling 80

- Big power key.

- Quiet fan operation.

- When working with the "three", the 10 A machine does not knock out.

- Cons Eurolux IWM-190

- There is no screen.

- There is no handle for lifting.

- It is easy to damage the seal sticker by removing the unit from the box.

- It overheats already at 120 A.

- Short welding cable 1.2 m.

- The maximum welding power of 190 A is too high - in practice, no more than 160.

Conclusion. This is one of the lightest MMA welding machines. Its mass is 3.7 kg. Dimensions 22x9x14 cm are convenient for transportation in the trunk of a car or even on a bicycle. The inverter is useful for installation work on the assembly of structures of sheet metal 1.0-3.0 mm.

Fubag IR 160

Another German MMA welding machine. It has a current range of 5-160 A. You can cook a "three" and "four". It is equipped with functions that prevent the electrode from sticking at a low current and contribute to the rapid excitation of the arc. Idling is 65 V. The overall efficiency of the device is 85%. Connects to a single-phase network. It withstands voltage drops up to 150 V. It is equipped with a mass cable with a clamp and an electrode holder. You can cook it continuously 4 minutes out of ten.

+ Pros of Fubag IR 160

- Indication of network availability and overheating.

- Convenient rigid handle and belt loops.

- Light weight 4.65 kg and dimensions 30x12x24 cm.

- Does not overload the household network thanks to a power of 6.6 kW.

- Cooks with voltage drops up to 150

- When the arc closes, the operating voltage drops to safe 20

- Soft ignition and pleasant rustling.

- Cons Fubag IR 160

- Almost 50% of the body is made of plastic.

- The duty cycle at 160 A is 40%.

- Need a machine to connect 25 A, otherwise it will knock out.

- Sold without a bag and case.

- Thin terminals.

- The cables in the kit are tough and twist the arm when bent.

Conclusion. This is the best welding inverter for working in very dusty rooms. It has a minimum of openings on the case, which reduces the path of garbage entry inside. The side covers are removed by unscrewing one screw at the base, which quickly opens the contents of the apparatus for purging. Maintenance takes 5 minutes and does not delay work in difficult construction conditions.

QUATTRO ELEMENTI B 165

The rating from the Italian brand, assembled at production facilities in China, continues. The model has a maximum current of 165 A, and consumes 4.9 kW of power. Welding with electrodes with a diameter of 2-4 mm is allowed. The product weighs only 4.8 kg. A minimum input voltage of 170 V is allowed. Welding wires have a cross section of 25 mm² and are not heated. The board provides visual control of the set values. Sold with leggings. Quick-connect connectors allow polarity reversal for two-touch welding.

+ Pros of QUATTRO ELEMENTI B 165

- There is a digital display for easy adjustment.

- Actually declared power - pulls the "four".

- Additional features will help you quickly learn how to cook a beginner.

- It turns out not bad to cook with half-baked electrodes due to turbo mode.

- For cooling, two fans and heat sink radiators are used at once.

- 80% duty cycle for high performance.

- In the country, the light does not blink while using welding.

- Cons QUATTRO ELEMENTI B 165

- It is difficult to set the exact number of amperes (± 3A).

- It is inconvenient to lift the device by the belt.

- Most welders in reviews lack cable lengths of 1.5 and 2.0 m.

- Flimsy latches.

- Power button on the back.

Conclusion. This is one of the inexpensive MMA case welding machines. If you often need to transport the inverter to a new place (your own cottage, neighbors are asked to boil something, the parents' house in the village, etc.d.), then with a suitcase he will better survive the transportation and maintain operability.

PATRIOT Max Welder DC-200

The welding machine from the American brand completes this category of rating. The budget model has a welding current range of 5-200 A, two indicators (overheating and mains), a regulator with a painted scale. The dimensions of the model are 30x12x19 cm. The inverter weighs 4.5 kg. The set includes wires 1.8 m long and a cross section of 25 mm². Idling is set to a value of 70 V. If you use the device at maximum, then the PV will turn out 60%. The equipment is simple for beginners and does not require special maintenance.

+ Pros of PATRIOT Max Welder DC-200

- Fast excitation of an electric arc.

- Quiet operation of the cooling system.

- Continues to work under reduced voltage.

- Brews the "Quartet", which is rare for household models.

- Clear adjustment of current.

- All functions really work, not a marketing ploy.

- The seam is even and minimal metal spatter.

- Cons PATRIOT Max Welder DC-200

- Small mass contact area - the cable overheats in this place.

- Power wires made of aluminum.

- Sometimes the cable length is not enough and you often have to rearrange the device or hang on the shoulder.

- The holder does not fix the electrode firmly.

Conclusion. This is the best MMA device, which is suitable not only for welding, but even for cutting. If you have to cut old heating pipes, water pipes or cut structural posts in a corner where you can’t crawl with a grinder on a site or in a house, this model with electrodes with a diameter of 3 mm can easily cut an arc of 2.0-5.0 mm thick metal.

The best semi-automatic welding machines MIG / MAG

To cook continuous seams in accelerated mode or work with thin body metal, semi-automatic machines are used. To work with the equipment you will need a shielding gas cylinder and a gearbox. Here are the TOP welding machines of this type, which are well established among users.

RESANTA SAIPA-220

The semiautomatic device headed the rating category. Reviews on the Internet show that the device cooks purely both in a shielding gas environment and when using flux-cored wire. Semi-automatic MIG has a welding current range of 10-220 A, which makes it suitable for body repair and installation of structures from profile pipes, corners. The wire feed takes place from the starboard side. Coils weighing up to 5 kg are placed inside. A single-phase device can be connected to a network with a voltage of 198-242 V.

+ Pluses RESAUT SAIPA-220

- Convenient torch with a long start button.

- Protection of the cable channel from breaking at the exit.

- Rigid handle for lifting and metal belt loops.

- Steel body.

- Easy opening of the side cover to replace the wire spool.

- Maximum welding current 220 A.

- It brews DC metal section up to 7 mm.

- Supports work with a flux wire.

- Cons RESANT SAIPA-220

- There is only an adjustment of amperes and wire feed speeds - volts are not adjustable.

- Designed only for wire 0.6-1.0 mm in diameter.

- In summer, the burner heats up quickly.

- The case is flimsy due to the thin iron, similar to tin.

- Short ground cable.

- No scoreboard.

Conclusion. We marked this semiautomatic device in the rating as one of the lightest in the line of powerful devices. The weight of the model is 14.65 kg. The feed mechanism with a coil and the power unit are made in a single housing, which simplifies the relocation and transportation. This is the best option for installation work. The welder only needs a long hose to connect the protective mixture from the cylinder.

Aurora OVERMAN 200

This is a semi-automatic welding machine for MIG / MAG, which is positioned as semi-professional. The equipment has a range of current strength of 5-200 A, and the welder can adjust the wire feed speed, the number of amperes and induction.This allows you to use the device to connect ferrous metals, stainless steel and even aluminum, but not on an industrial scale (for private purposes). Power 5.6 kW does not create a load on a single-phase network. Idling 43 V requires a good surface finish for comfortable ignition of the arc.

+ Pros of Aurora OVERMAN 200

- The internal location of the coil.

- You can adjust the wire feed speed from 2 to 15 m per minute.

- Compact dimensions of the semiautomatic device 48x19x46 cm.

- The power button is located on the front.

- Separate voltage regulation (induction), affecting the degree of meltability of the filler metal.

- Convenient removable cover for maintenance and replacement of consumables.

- Rigid handle for rearrangement.

- Cons Aurora OVERMAN 200

- Works only with 0.6, 0.8 and 1.0 mm wire.

- Duration of inclusion no more than 40%.

- Thin metal on the body 0.8 mm.

- The burner quickly heats up at maximum power.

- Pores remain on aluminum.

Conclusion. This semiautomatic device for MIG welding is distinguished by the ability to work in frosts up to -20 degrees. If you need to regularly perform welding in an unheated room or outdoors, it is best to choose this machine. The model has a good insulation class, and the cable channel remains flexible in the cold.

RESANTA SAIPA-200

This category of rating is completed by a welding machine with a working current of 30-200 A. Semi-automatic welding of MIG / MAG is carried out with direct current. Model weighs 14.35 kg. The rectangular case with 6 legs stands stably even on an inclined surface. The case is completely made of metal, so it is almost impossible to damage the device with a blow. The combined execution of the feed mechanism and the power source gave a compact size.

+ Pros RESAUT SAIPA-200

- Steel body with numerous perforations for cooling.

- Loops for winding the cable.

- Rigid handle for easy loading into the machine.

- A removable burner enhances maintainability.

- Brews steel 5 mm thick.

- Protection from overheating rarely works.

- Power surges 190-240 V do not affect operation.

- Cons RESANT SAIPA-200

- The current decreases only to 30 A - it is difficult to cook thin metal 0.8 mm.

- Not designed for wire with a diameter of 1.2 mm or more.

- No adjustment of the inductance of the welding arc.

- Need a connection line with a cross-section of copper 2.5 mm².

- With cored wire, seams are only for non-compliant structures.

Conclusion. This is an excellent semi-automatic for body repair in the garage. Its PV at a current of 200 A is 70%, so with a power of 140 A it will work for 6-8 hours without a break. Users in reviews report that protection against overheating is extremely rare, despite intensive use.

The best universal devices MMA + MIG / MAG

If you need to alternate welding of thick metal (3-7 mm) and thin (0.8-2.0 mm), then it is practical to buy a universal type welding machine with the ability to attach both a conventional holder and a semiautomatic torch. The price of such equipment is higher, but the functionality and capabilities are wider. Pay attention to the following popular models that have collected positive reviews.

Svarog REAL MIG 200

A universal type welding machine that produces up to 160 A in MMA mode and 200 A in MIG mode. It operates on a single-phase 220 V network and consumes 7.7 kW of power. It is completed with a torch with a sleeve of 3 m.

+ Pros Svarog REAL MIG 200

- Rubberized legs and upper corners of the device.

- Durable tough grip on top.

- Two fans for accelerated cooling.

- Includes holder and burner, as well as ground cable and interchangeable nozzles.

- Supports adjustment of wire speed 1.5-14 m / min.

- There is an inductance control function.

- It is possible to work with cored wire.

- Cons Svarog REAL MIG 200

- Two-roll feed mechanism.

- No scoreboard.

- The power button is located on the back.

- Sold without instructions.

- The side compartment lid may not fit snugly.

Conclusion. This is a household semiautomatic device and an inverter for RDS, which has professional characteristics.If you are already quite an experienced welder and demanding on the quality of the seams even for products in the garage, then it will suit you.

RESANTA SAIPA-135

Budget semiautomatic device with MMA welding function. Has an adjustable current strength of 30-110 A and wire feed speed. Provides an open circuit voltage of 65 V for easy arc excitation. PV is 70%. It is equipped with a burner and grounding, but the electrode holder will have to be purchased separately.

+ Pros RESANT SAIPA-135

- It cooks well both with carbon dioxide and with the mixture.

- Loops for winding the cable.

- The power button is placed on the front panel.

- Easy to set up and maintain.

- There is a preliminary purge of gas, launched from the burner.

- Compatible with field generator.

- Cons RESANT SAIPA-135

- Welding current limit 110 A.

- Only 1 kg reel is placed inside.

- Short sleeve burner.

- It splashes metal when voltage drops.

Conclusion. Another model for body repair. A weight of 9.8 kg does not complicate the movement around the machine. The current strength of 110 A is suitable for welding metal with a cross section of up to 3 mm. With it, it will be easy to weld wings, sills, patch the arches, the bottom.

Foxweld invermig 205

Universal device for welding with coated electrodes and wire from a coil. The Euro burner connector allows you to replace it after a breakdown. It supports gas welding and self-shielding wire. The open circuit voltage is 65 V. The current strength varies from 20 to 200 A. Due to the lack of a handle, you need a trolley to transport the device, weighing 12.4 kg. Permissible installation of coils weighing up to 2 kg.

+ Pros of Foxweld Invermig 205

- Intuitive controls (all switches have graphic images).

- Separate burner outlet and holder.

- When welding with a mixture, there is almost no spray.

- Soft arc with good handling.

- They rarely break.

- Assembly in Italy.

- Cons Foxweld Invermig 205

- Two-roll feed mechanism.

- Only one fan for cooling.

- Power button on the back.

- No carrying handle.

- Inside the contacts are not varnished and when moisture condenses, blocking occurs (drying is needed).

Conclusion. This is a semi-professional welding machine of a universal type. According to the reviews of the masters, it withstands harsh construction conditions (dust, dirt, falls) and lasts 5 years without a single breakdown. 100% PV promotes high-quality welding of 10 mm thick iron throughout the entire working day.

SPECIAL MAG170 Invertor

The inverter with the simplest settings that supports MMA and MIG modes completes the rating category. The welding machine has a current strength of 30-160 A and is suitable for working with 0.6-0.8 mm wire. The weight of the coil can be 1-5 kg. Idling is 56 V. The model weighs 10 kg. The presence of a handle allows you to use the device without a cart. Power 5.9 kW does not load the household network.

+ Pros SPECIAL MAG170 Invertor

- Cooks with gas and flux-cored wire.

- You can control the inductance.

- The arc ignites easily.

- A minimum of plastic in the design.

- It does not overheat.

- Reliable connector outputs without backlash.

- With the "subsidence" of voltage there is no spraying of metal.

- Cons SPECIAL MAG170 Invertor

- MIG burner cannot be removed.

- Only for 0.6-0.8 mm wire.

- The wire feed speed is regulated inside the housing on the mechanism.

- There is no display for installing the I-V characteristic.

Conclusion. This is one of the most inexpensive universal welding machines with a complete set for a novice welder. In a set to the inverter go gaiters, a mask and a brush for metal. The kit already includes a burner, ground cable and electrode holder. Two nozzles and 1 kg of wire are also provided. All you need to start welding training.

The best universal devices MMA + TIG

For welding ferrous metal and neat welds on stainless steel, universal devices with TIG and MMA modes are chosen. Here is a ranking of the best models with such features.

RESANTA SAI-230 HELL

Domestic product with TIG and MMA modes.It is equipped with connectors for connecting contacts from the burner button and the gas line, so not only valve options are suitable, but also full-fledged burners with high-frequency ignition. The range of current strength is 10-230 A. There are functions that protect against sticking of the electrode. Idling 85 V contributes to the rapid excitation of the arc. PV is acceptable 70%.

+ Pros RESAI SAI-230 HELL

- The body is made of steel.

- Includes holder for melting electrodes and torch for tungsten needles.

- Light weight 10 kg.

- Tight connectors do not allow plug-in parts to dangle and get warm.

- Uniform strong seam.

- No sticking of the electrode.

- It does not knock out even when used from an old counter with ceramic plugs.

- Cons RESANT SAI-230 HELL

- When the moisture is pulled in, the circuit protection is activated and needs to be dried.

- No switching to AC.

- The welders in the reviews lack the length of the torch and the cable holder.

Conclusion. In this universal device, in addition to current strength, the joint leg can be adjusted. Depending on this, the roller on the surface will be either higher or more fused into the base metal. Such equipment is even suitable for connecting critical structures under inspection by a flaw detector. The power reserve of 230 A allows them to connect metal up to 20 mm in thickness.

ELITECH IS 200H

Compact universal welding machine with TIG mode and contact ignition, as well as for MMA welding. The maximum welding current reaches 200 A, with a power of 7 kW. Allowed to work with electrodes with a diameter of 2-5 mm. If overheated, the protection will work. It can cook 6 minutes out of ten without a break at an ambient temperature of +25 degrees. The input voltage is 140-250 V.

+ Pros of ELITECH IS 200H

- A simple device with a minimum of parts for breakage.

- There are useful features to prevent sticking and easy arc burning.

- Low cost.

- It is possible to cut metal with a section of 3 mm by electrodes.

- Inside, protective curtains that prevent the winding from shorting to the housing.

- Cons ELITECH IS 200N

- A simple device with a minimum of parts for breakage.

- There are useful features to prevent sticking and easy arc burning.

- Low cost.

- You can cut metal with a cross section of 3 mm with electrodes.

- Inside, protective curtains that prevent the winding from shorting to the housing.

Conclusion. Pay attention to the weight of the device - 2.8 kg. Its dimensions are 22x10x15 cm. The unit is convenient to carry in your hands. With a long hose from the cylinder, they will be able to cook at the top of a large stainless steel tank. My shoulder almost never gets tired even for several hours in a row. This is an excellent choice for a remote work place, where you need to stretch a 50-meter-long carrying device. The device will be able to function from a low voltage of 140 V.

Svarog PRO ARC 180

A good device in terms of quality and price. Supports manual arc welding with coated electrodes and argon. The current range is 10-180 A with a power of 8 kW. The equipment has a digital screen. PV at the "maximum speed" reaches 60%. The input voltage is permissible 187-253 V. Varya DC and electrodes up to 4 mm in diameter.

+ Pros Svarog PRO ARC 180

- There are two ceramic nozzles for the TIG burner in the kit.

- 3 m cable (weight and holder).

- Steady arc and fast ignition.

- Light weight 4.7 kg.

- Display to control settings.

- Real arc boost at low amperes (up to 50).

- Unpretentious in working at ambient temperature.

- Cons Svarog PRO ARC 180

- Cable cross section 16 mm² leads to overheating of the wire.

- Protective plastic panels are constantly loosened on the holder.

- The power cord is rough.

- Expensive repairs due to the performance with a single board.

- Contact type of electrode ignition for argon-arc welding.

Conclusion. The welding machine is attractive with quality factory assembly. Although it is produced at the Jasic Chinese factory, it is the best enterprise in China.The manufacturer gives a guarantee for a model of 5 years. According to welders, these inverters rarely break. All declared functions work.

Wert SWI 190

Another easy-to-configure universal welding machine. The inverter supports two modes with a current strength of 20-190 A. It can be connected to a network of 140-250 V. It produces only direct current, therefore it is suitable for welding stainless steel and ferrous metals. PV is 60%. Idling 68 V provides a smooth ignition of the arc. Case dimensions - 25х10х15 cm.

+ Pros of Wert SWI 190

- Steel body.

- The controls are "recessed" inward so as not to stray from an accidental touch.

- Useful features for beginners.

- Supply voltage 140-250

- Weight 2.4 kg.

- Perfectly cooks "two" and "three".

- Power line made of copper.

- Cons Wert SWI 190

- No display.

- Only contact ignition of a tungsten electrode.

- Sold without a torch for argon arc welding.

- Flimsy mass clamp.

Conclusion. We want to highlight this device as the best for power supply from wiring with a thin section. If 2 mm² wires are laid in the walls of the house or garage, they will withstand the connection of the welder and will not melt, since its power is 3.5 kW.