Spot welding machines: types, how to choose, the best models

To choose the right spot welding machine, you need to understand the capabilities and key parameters of the equipment. In addition, it is useful to read reviews of welders about specific models. All this is in our review, which will help you choose the equipment that will cope with the upcoming tasks.

The selection of goods was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.

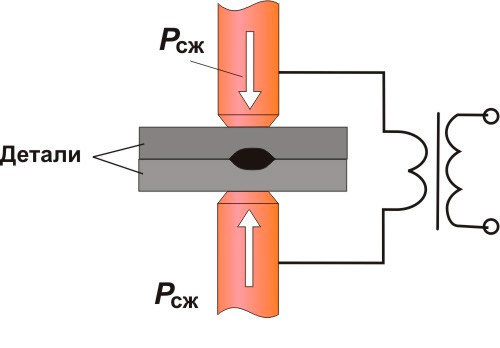

Spot welding principle

First, we consider the device and principle of operation of spot welding machines. The equipment is connected to a 220 or 380 V network and converts alternating current into direct current. For this, inverter technology is used. A step-down transformer inside reduces the number of volts to 12-48, and increases amperage.

A cable is attached to the power source, at the end of which a gun or console with an electrode is attached. The latter refers to a non-consumable type (usually an alloy of copper with chromium). It should be several times thicker than the cross section of the metal being welded. A short touch of the end of the electrode to the product produces spot heating, which melts the iron. The metal molecules are mixed, forming a single crystal lattice. It turns out a point connection. If you break it, then on one side there will be a depression (crater), and on the other core.

Since the contact is made by an electrode with a small cross section, the surrounding surface heats up less and does not deform. Thus, it is possible to connect sheet blanks, wire or weld rods to a plane (pot handles, etc.).

Diagram of the process of spot welding.

The advantages of spot welding

Spot welding is in demand in body repair. With its help, the end of the reverse hammer is welded to damaged places, with which dents are pulled. This type of welding is also used in the manufacture of metal utensils, various fences.

Among the advantages of spot welding, the following parameters can be distinguished:

- Neat and precise seams.

- Reducing the cost of electricity and supplies (no consumable electrode, no gas needed, as in a semi-automatic machine).

- High performance.

- Highly qualified personnel are not required (it is enough to show a couple of times how to use and give to practice on rough details).

- When working with product thickness 0.5-1.0 mm there are no burn-throughs.

- There is no need for subsequent machining of the joints.

How to choose a spot welding machine

To figure out how to choose spot welding, you need to remember seven key parameters that you should pay attention to before buying. There are additional factors that play a role only in certain operating conditions.

Types of spot welding machines

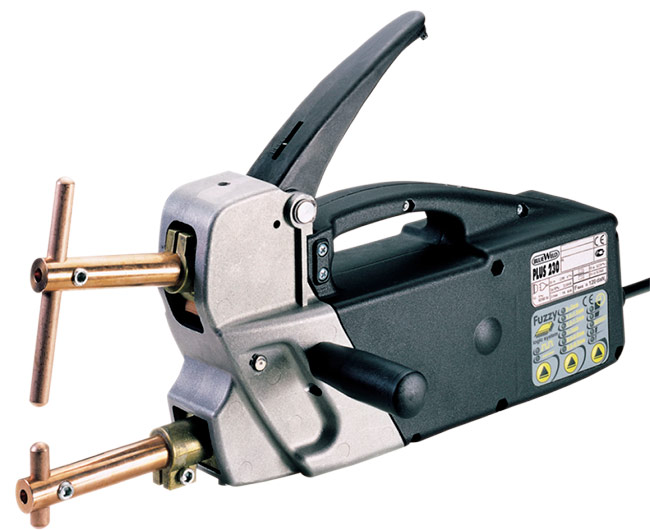

All equipment capable of spot welding is divided into two categories: portable and stationary. The first type is compact in size within 30x20x30 cm and weighs up to 16 kg. Such models are able to weld metal with a cross section of 1.5 + 1.5 mm. The maximum figure can reach 5 mm.Portable goods are relevant for body repair or the release of large metal structures (doors, gates, racks). The device can be moved around the product and welded.

Portable spot welding machine.

Stationary machines for spot welding are used in factories. With their help they perform assembly of products that the operator can hold in his hands. The same type of compounds in serial production is created very quickly, which contributes to increased productivity. But such installations take up a lot of space due to the dimensions of 50x60x100 cm and can weigh up to 100 kg. A powerful current source allows you to weld metal with a total thickness of up to 8 mm.

Stationary apparatus for spot welding.

Exposure modes

Spot welding machines can act on workpieces using one of two methods.

One-sided spot welding

One-way mode is implemented in models called spotters. They are equipped with a pistol with a rod and a reverse hammer, at the end of which there is a copper electrode in the form of a triangular star. Having grabbed electric welding to the surface, it is possible to perform backward strokes, pulling the dented metal.

Spotter for one-sided spot welding.

One-sided exposure is justified in case of difficult access to the back of the structure (you need to remove the door trim, dismantle the wing of the machine), or when the product is too large. In this way, you can also weld washers or a comb to the surface in order to act simultaneously on a large area, pulling all the elements at once with hooks.

Spotter operation for one-sided spot welding.

Double-sided spot welding

Double-sided welding is used for joining sheet metal with an overlap. To do this, the devices are equipped with mites, wrapping the product. The maximum distance of the connection point from the edge of the structure depends on the departure of the consoles. This parameter can be from 12 to 50 cm. In such devices, the lower console is stationary, and the upper one is lowered, simultaneously pressing and warming up.

Double-sided spot welding pliers.

Mode of operation

The operating mode of the device is soft and hard, which depends on the characteristics of the current. In the first case, a low current density is used, but the welding cycle is performed with an extended duration of 2-5 seconds. This allows the use of electrodes with a smaller cross-section (it can be equal to the thickness of the workpiece) and does not press hard with pliers.

In the second case, a current of higher density is used, and the cycle lasts shorter - 0.2-1.5 s. This mode provides increased speed, but requires strong compression of the workpieces and the diameter of the electrode, several times higher than the total section of the welded parts.

Maximum welding current

The capabilities of equipment for spot welding depend on the maximum welding current. The value of 3000 A allows connecting parts with a total cross section of up to 3 mm. Devices with a rating of 6000 A can weld steel up to 4-5 mm. Industrial machines 10000-16000 A allow you to connect workpieces up to 9 mm (in total).

Maximum thickness of welded sheets

An important parameter showing what maximum cross-section the apparatus can boil. If you ignore this value and use the equipment on thicker parts, then the quality of the connection is reduced. The parameter can be specified as general, for example, “5 mm”, or divided into two parts - “2.5 + 2.5 mm”, which will mean the same thing. There are industrial versions that can weld three sheets of steel together. Then this is referred to as “3 + 3 + 3 mm”.

Voltage for connection

To connect the device to the network, a single-phase voltage of 220 V or a three-phase line of 380 V is required. This is directly indicated in the instructions for the product and determines where it will be used. Power consumption from 3 to 12 kW will tell you whether it is possible to include the device in a normal household network (usually it is better not to include more than 5 kW so as not to melt the wiring).

Control method

The cheapest devices are manually controlled. In some models it is not even possible to set the current strength - it always works at maximum.The operator himself squeezes the pincers with his hands and monitors the contact time of the electrodes to form the desired penetration. For a high-quality connection, you first need to test the device on rough blanks with the same thickness as the main product. Having determined how much time is needed for the clamp, you can proceed to welding. There are devices with adjustable amperage, which slightly simplify the work with metals of different thicknesses.

Microprocessor (synergistic) control greatly facilitates the work. The welder indicates on the panel the type of connection being performed (welding of washers, wires, lap welding, etc.), as well as the thickness of the product. Synergetic control itself selects the optimal parameters for welding, applies current and turns it off. The operator can only bring the electrodes and put them in the right place. But such models are much more expensive.

Extra options

If continuous operation is required, pay attention to the type of cooling. Devices with a water system and a radiator remove heat faster and have a longer life.

The spotter will definitely need a gun and a reverse hammer. To perform welding using copper electrodes, which are consumables. For mobile devices with a weight of 13 kg or more, it is practical to purchase a trolley to transport them on casters.

The best spot welding machines

If you need contact spot welding for a home workshop or small production, then pay attention to the following models that have already been tested by customers and received positive feedback.

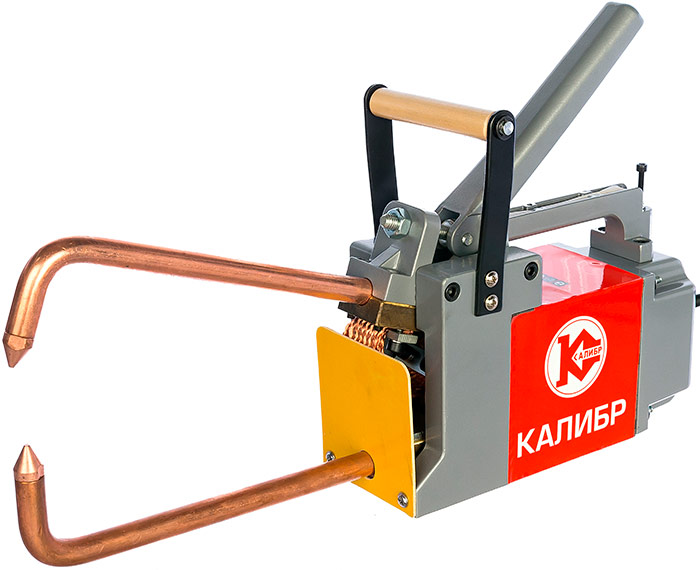

Caliber SVA-1.5 AK

This machine for spot welding from the Russian brand "Caliber". The SVA-1.5 AK model is powered from a single-phase 220 V network and consumes 8 kW. The housing is dustproof according to IP20. The kit includes a handle and spare tips. The control is completely manual, where the welder himself adjusts the clamp time and amperage. A limit bolt is provided under the movable handle to set the clamp force.

Pros Caliber SVA-1.5 AK

- Powerful return spring for breeding ticks.

- Large grip for quick shifting.

- It turns out a neat point that can not be broken by hands.

- No machining of the joint is required.

Cons Caliber SVA-1.5 AK

- Cable of the upper console (pigtail) made of copper-plated aluminum (overheats).

- The power key is awkwardly located.

- Hands weigh 16 kg.

- Wiring with a cross section of 4 mm² is required, in view of a power of 8 kW.

Conclusion. This is the best apparatus for the ratio of cost and power of penetration. Users in the reviews share that they easily weld sheet metal 2 + 2 mm together, performing 15 dots per minute. If you want to connect the wire, then the model will cope with the cross section of the bars 5 + 5 mm. But the connection needs a powerful network, so you should not choose such spot welding for the garage.

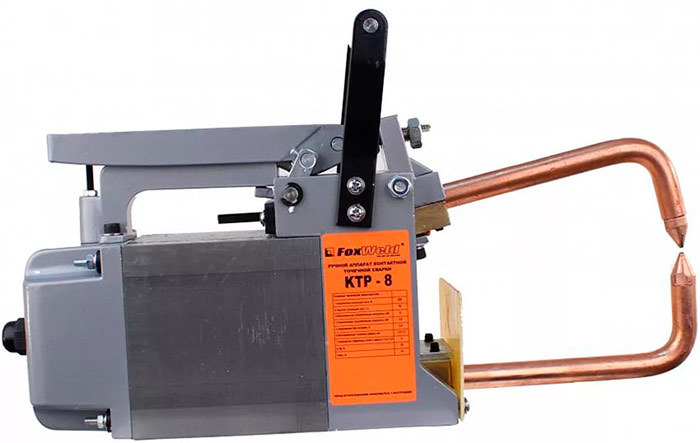

Foxweld KTR-8 3097

In second place in the ranking of goods from the Italian brand Foxweld. The equipment for spot welding has two copper brackets, a handle for clamping, a baffle plate. The power of the current source is 8 kW and the apparatus is capable of cooking with 6000 A. The manufacturer claims that the inverter will easily connect two workpieces with a cross section of 1.5 + 1.5 mm. The model belongs to the professional class and has IP21 housing protection.

Pros of Foxweld KTR-8 3097

- Large handle for lifting the device.

- Relatively small dimensions 41x10x23 cm.

- The extension of the electrodes of 15 cm allows you to start large parts between them.

- Increased welding current power.

Cons Foxweld KTR-8 3097

- There is a slight backlash, due to which the electrodes do not exactly converge with each other.

- You need good wiring from 4 mm².

- It is often difficult to rearrange due to a weight of 14 kg.

- Power is not adjustable.

Conclusion. Judging by the reviews, this machine for spot welding, most users use for the manufacture of metal doors. Welders say that it’s much more convenient than operating as a semiautomatic device and after welding no additional joint cleaning is required.

FUBAG TS 2600 38 666

And here is a spot welding machine called a spotter. It is designed to perform single-sided tacking on metal with a cross section of up to 1.5 mm. The maximum current is 2800 A. The dimensions of the equipment are 20x32x18 cm. When connected to a single-phase network, the device consumes 5.4 kW, so it can be used in a garage or in a country house. Included with it is a gun and a rod with a return hammer. There are three star electrodes and one carbon electrode for heating a metal surface.

Pros of FUBAG TS 2600 38 666

- Switch for welding with carbon and copper electrodes.

- Light indication of overheating and network availability.

- Four operating modes.

- Creates a reliable connection.

Cons FUBAG TS 2600 38 666

- The heavy weight of 14 kg is often inconvenient to rearrange.

- High price.

- There is no adjustment of amperage current (only by welding method).

Conclusion. This model was developed for car body repair and is able to work in several modes: welding corrugated wire, rings, heating the surface with a carbon electrode, tacking the “star”. Pay attention to the powerful reverse hammer on the gun. The weight of the weight is 1.1 kg, which ensures quick pulling of dents.

RedHotDot HAMMER IT 275116

The Hammer brand is available in Italy. The IT 275116 model produces a maximum current of 3200 A. This allows welding sheet metal with a cross section of 1.5 + 1.5 mm. Connecting to a single-phase 220 V network and consuming 3 kW does not overload household wiring, so you can even use the device in a garage. The digital display is convenient for visual control of the entered parameters. The indicator shows overload trip. Included with the spotter is a gun with interchangeable nozzles.

Pros of RedHotDot HAMMER IT 275116

- Housing protection

- Does not create excessive load on the network due to the power of 3 kW.

- Small dimensions 30x18x26 cm.

- Deep penetration and strong connection.

Cons RedHotDot HAMMER IT 275116

- High price.

- It weighs over 16 kg.

- For some welders, the reverse hammer design seems weak.

Conclusion. The model for spot welding is notable for its synergetic control, where the welder selects one of six modes, depending on the configuration of the element being welded. On a digital board metal thickness is established. The microprocessor itself selects the optimal parameters for the existing task.

FoxWeld MTR-25 3373

Further in the ranking is a spot welding machine, which is designed for operation inside the production workshop. The device needs to be connected to a three-phase network of 380 V. It has mechanical control, and the clamp is compressed by a foot drive. The welder's hands can support the workpiece at this time. The power of the equipment is 25 kW. The case has dimensions of 87x40x121 cm and weighs 100 kg.

Pros of FoxWeld MTR-25 3373

- Simple operation.

- Long service life.

- With everyday work does not break.

- Starting squeezing the ticks with the pedal - hands are always free.

Cons FoxWeld MTR-25 3373

- Very high cost.

- A weight of 100 kg requires a solid foundation under the machine.

- Users do not have enough table under the ticks to turn over the workpieces.

- It is often necessary to sharpen electrodes with heavy use.

Conclusion. We recommend this machine for serial spot welding in production. The model has a welding current of 16,000 A and is capable of boiling workpieces with a thickness of 2.5 + 2.5 mm. One point is completed in 10 seconds, which allows you to immediately put 6 stitches per minute. Another feature of the product is water cooling in a system with a radiator. It removes excess heat and extends the time of continuous operation.

WIEDER KRAFT WDK-6000

The review ends with a spotter on a trolley. It contains a gun for spot welding and a reverse hammer. The model produces a maximum current of 4400 A. The case is protected according to the IP23 standard, so the device can be operated outdoors when it rains (finish leveling the body part and put it into the room).Input power is 11 kW. The welding time can be adjusted from 1 to 10 s. The welder does not need to follow this - the device turns off the welding current on its own. Grips are strong and without burns.

Pros of WIEDER KRAFT WDK-6000

- Can connect to 220 V.

- Increased Reliability.

- Eight welding modes.

- Digital display and synergistic control.

Cons WIEDER KRAFT WDK-6000

- High price.

- No cooling fan.

- It is necessary to provide a place for the apparatus with dimensions of 60x50x95 cm.

Conclusion. This spotter for spot welding is notable for the performance on the trolley. In this case, the power source is located on top, so you do not need to bend to enter the settings. Below there is enough space for cables, consumables and tools. The trolley is equipped with wheels, where the two front wheels rotate 360 degrees to the sides. This makes it easy to quickly move around the workshop and is great for a workshop to restore body geometry while moving around a car.