How to sharpen a drill for metal and concrete with your own hands

It does not require special evidence that the drill loses its sharpness during operation, that is, simply speaking, it is dull. A dull drill does not cause concern until it is needed. Then it suddenly turns out that working with a worn or blunt drill is impossible. It remains only to regret that the geometry and size of the drill have not been restored in time. This article will tell you how to sharpen a twist drill, as well as a hard drill for drilling concrete.

How to sharpen a spiral drill

You don’t have to worry about sharpening a drill on wood; you can work with such a drill for many months and even years without any sharpening. Unfortunately, this cannot be said about a drill for metal, which must be necessarily sharp. That is, metal can be drilled exclusively with a sharp, well-sharpened drill.

A sharp creak at the beginning of drilling is characteristic for the loss of sharpness of the drill. A drill not sharpened in time produces more heat and thus wears out even faster than a sharp one.

You can sharpen the drill on special machines or using tools. Naturally, if possible, it is preferable to do this on special equipment. But in the home workshop of such machines, as a rule, there are none, so you have to use a conventional electric stone grinder.

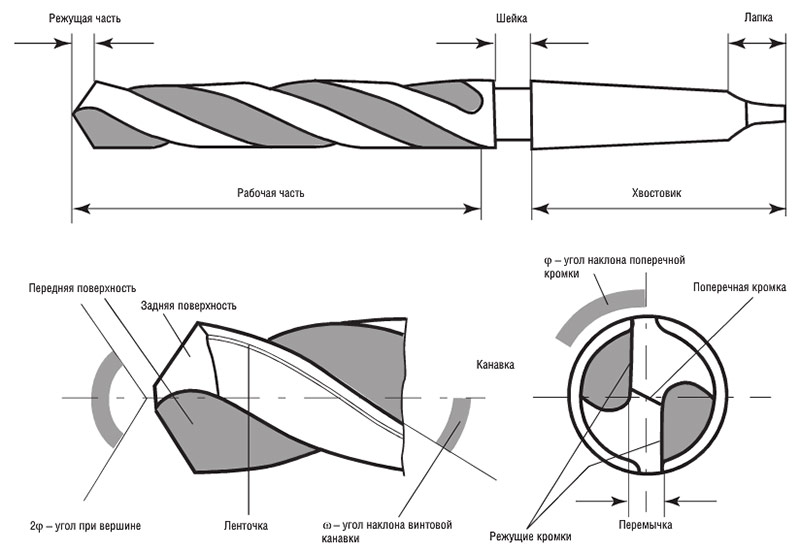

The main components of a twist drill.

The main components of a twist drill.

So, consider how to sharpen a drill bit for metal?The type of sharpening depends on the shape that should be given to the rear surface of the drill and can be single-plane, two-plane, conical, cylindrical and screw.

Sharpening of the drill is carried out along the rear faces. Both teeth (feathers) of the drill should be sharpened exactly the same. Manually doing this is not easy. It is also not easy to manually maintain the desired shape of the rear face and the desired rear angle.

1. Single-plane sharpening of the drill is characterized by the fact that the back surface of the pen is made in the form of one plane. The rear angle in this case ranges from 28-30 °. The drill is simply attached to the circle, so that the cutting part runs parallel to the circle and without rotating, without moving the drill, sharpening is performed. With such sharpening during drilling, the cutting edges of the drill can become chipped, which is a disadvantage of this sharpening method. This is the easiest manual sharpening method that can be used for thin drills with a diameter of up to 3 mm.

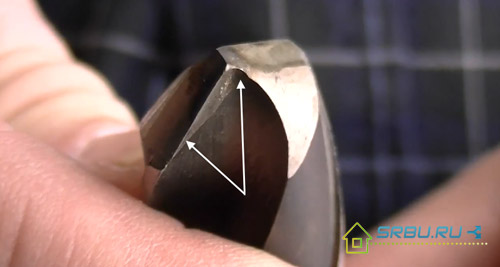

2. Drills with a diameter of more than 3 mm are preferably sharpened conically. Manually without skills, such a sharpening is difficult, but possible. The drill is taken with the left hand at the working part as close to the intake cone as possible, and with the right hand at the tail. The drill is pressed against the end of the grinding stone by the cutting edge and the surface of the rear part, and slightly sways with the right hand, creating a conical surface on the rear feather face. During sharpening, the drill does not come off the stone, hand movements are slow and smooth. For the second pen, everything repeats in the same way.

Bring the drill bit with the cutting edge to the grinding wheel.

We swing the drill down, and then again up.

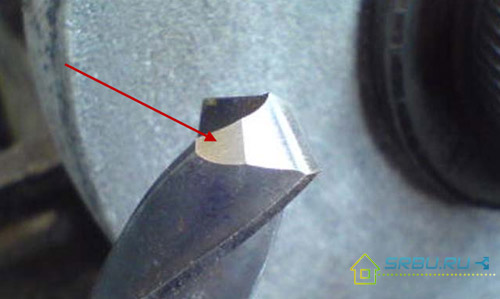

When sharpening, you must try to maintain the original shape of the factory surface of the rear part as much as possible in order to maintain the necessary rear angles. If sharpening is done correctly, then on drills with a diameter of up to 10 mm it is quite sufficient.With diameters above 10 mm, this sharpening can be improved by grinding the front surface, as shown in the photo:

Grind the front surface.

What is the point of undermining? By reducing the rake angle and increasing the angle of the cutting edge, resistance to chipping increases, which increases the resource of the drill. In addition, the width of the transverse edge becomes smaller. The transverse edge does not drill, but scrapes the metal in the central part of the hole. The second figure clearly shows that here it is shortened, which facilitates drilling.

For drills with a selected small back angle, you can further sharpen the back surface. In this case, the drill is less than a third in the drilling hole with the rear surface. See photo:

Grind the back surface.

In production conditions, after sharpening, as a rule, a fine-tuning is done, which smooths the surface, removing fine notches. The drill, on which the debugging is done, wears out less than just a sharpened drill. If possible, fine-tuning should be done.

For finishing, you need to use grinding round stones made of green silicon carbide (grade 63C, grain size 5-6, hardness M3-CM1) on a bakelite bond, as well as circles from the elbo LO (grain size 6-8) on a bakelite bond.

Below we present to your attention an excellent selection of training videos by watching which you can definitely sharpen your drills.

Video: Manual sharpening of twist drills. Part 1.

Video: Sharpening twist drills. Part 2.

Video: Stitching jumper ribs. Part - 3.

Video: Sharpening drills - application.

How to sharpen a soldering drill with soldering

The drill bit may also become dull. A dull drill overheats during operation, drills poorly and makes a strong screeching sound. Of course, you can change the drill by buying a new one, but it is better to save and sharpen it with your own hands. To do this, you will need a grinding machine (electric sharpener) with a diamond stone and coolant. An ordinary emery stone for sharpening a drill from a win is not suitable. Before you start sharpening, make sure that it is possible, in principle. To do this, measure the height of the cutting part of the drill. When the height of the cutting part of the drill, i.e. soldering about 10 mm, sharpening is possible.

Do not forget: the harder the material, the lower the sharpening speed should be. The angular speed (the number of revolutions of rotation of the stone) when sharpening the core drill should be reduced, regardless of which tool is used for sharpening.

Sharpening the drill is carried out by short touches with an emery stone drill. The drill bit is sharpened quickly, as a rule, you only need to tweak the lapped edges there, so you should carefully monitor the process so as not to cut off the excess from the working drill bit surface.

Drills with solderings are recommended to be sharpened similarly to simple drills of small diameter, i.e. sharpen the back surface flat. At the same time, the back surface should be sharpened, as shown in the photo, grinding the drill until it is soldered:

Sharpened solder drill.

It is advisable to grind the front surface. If the soldering has already been sharpened to the drill itself, then just cannot be dispensed with, since the soft metal goes to the cutting edge from the front surface. The front surface is simultaneously sharpened so that the thickness of the center of the solder becomes less.

Grinding from the front surface.

When sharpening the drill, try to be precise and carefully make sure that its cutting sides are the same size. If this cannot be achieved, then the shifted center of the spine will necessarily lead to the fact that the drilling hole will be enlarged and uneven. Regardless of the device on which sharpening is performed, it is necessary to control the ratio of the front and rear corners of the cutting edge in the direction of rotation. Another rule that must be followed in order to properly sharpen a drill bit on concrete: the harder the material, the greater the angle of sharpening. For victory, it is 170 degrees.

During sharpening, the drill must not be allowed to heat, ascracks may appear and peeling of carbide plates is possible. In order to prevent this, periodically cool the drill with liquid. For cooling, you can use ordinary water.

We suggest watching a selection of videos on sharpening drills with victorious soldering.

Video: Sharpening drill bits for a perforator. Part 1.

Video: Sharpening drill bits for a perforator. Part 2.