Semi-automatic burner: types, how to choose, the best models

MIG / MAG welding is characterized by increased productivity and continuous connections. The quality of the seam depends on the characteristics of the apparatus and the skills of the welder, but the torch of the welding semiautomatic device also affects the convenience of the process, therefore it must be correctly selected. We will discuss the device and types of torches for welding semiautomatic devices, and also make an overview of the most successful models.

The selection of goods was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.

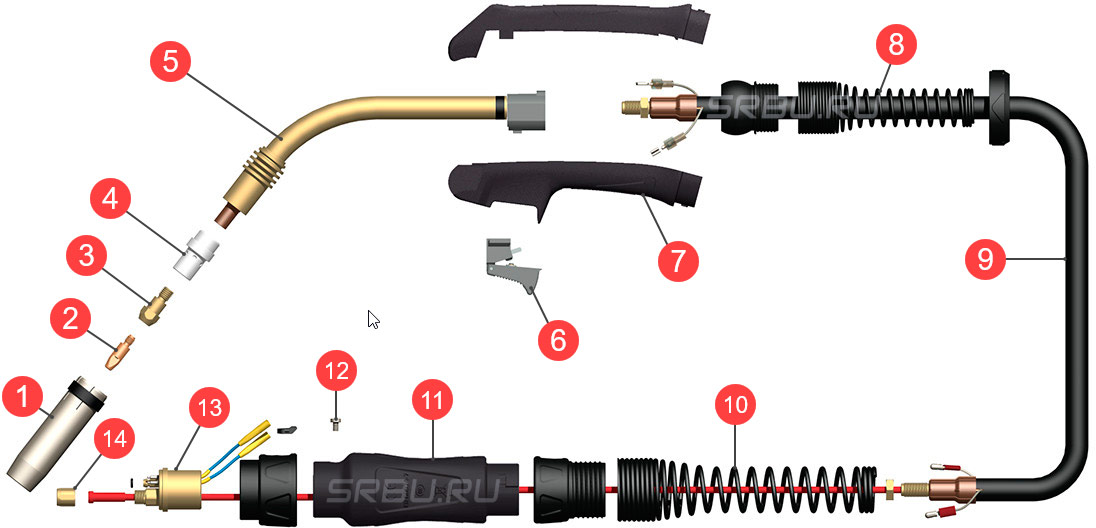

Gas burner assembly with sleeve

To understand the choice of components, we consider a burner device for a semiautomatic device, which will help to understand which elements account for the most load during operation.

1. The nozzle is conical.

2. Current tip.

3. Tip holder.

4. Gas distributor.

5. Mouthpiece.

6. Button.

7. Lever.

8. Connecting spring

9. Coaxial cable.

10. Connecting spring

11. Box for air cooling.

12. Screw.

13. Central collector.

14. Nut.

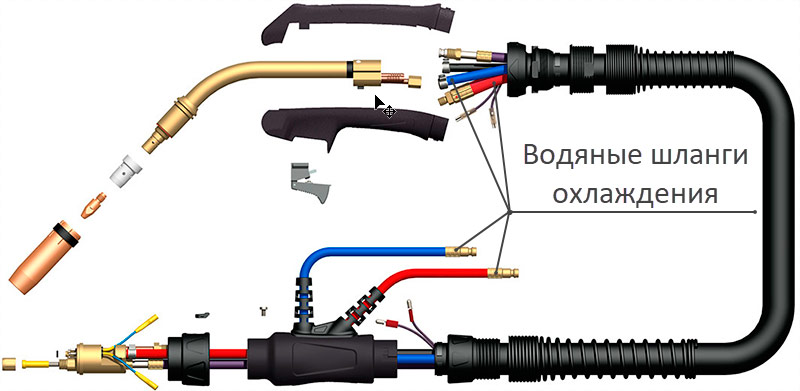

Water-cooled burner device.

Varieties of gas burners

Semi-automatic burners differ primarily in the permitted maximum current. It depends on what thickness of the metal they can weld (in combination with the power of the semiautomatic device). There are domestic and semi-professional torches with an indicator of 150-180 A. Next are accessories for 200-250 A. In major industries, torches are used that can withstand welding at a current of 300-400 A.

There are still torches for working at the welding table (the welding sleeve for the semiautomatic device is short - 2-3 m), and torches for assembling volumetric structures in the workshop (hose package length 4-5 m).

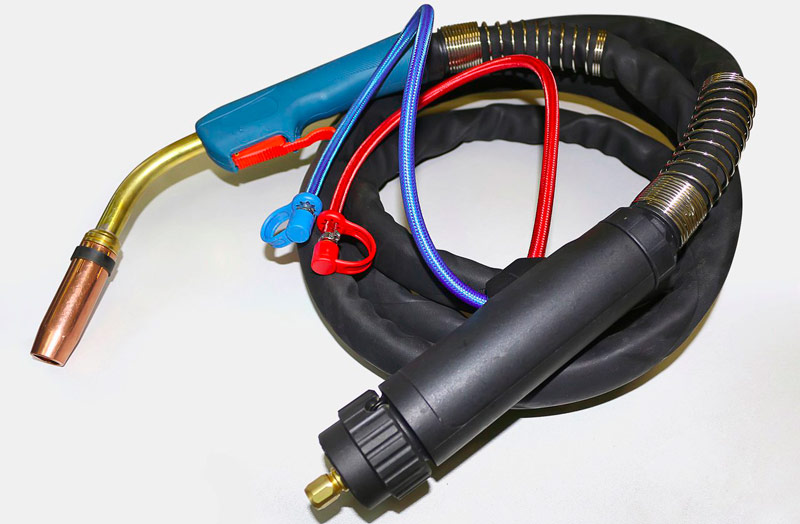

The last difference is the type of cooling, which is air and liquid. In the first case, heat escapes into the air, and gas purging is additionally performed from the inside. In the second case, the burner has a feed and return channel for the circulation of fluid, which is carried out from the pump.

Water-cooled burner.

The type of cooling affects the duration and cost of the goods.

How to choose a gas torch and welding sleeve for a semiautomatic device

When choosing a model, consider the following six factors.

Maximum welding current limit

This parameter should correspond to the characteristics of the device. If your semiautomatic device produces 300 A, then the burner indicator should be no less. In the case when welding is always carried out at low currents (100-120 A), you can buy a torch designed for such a value, but this will limit the capabilities of the device.

The length of the sleeve

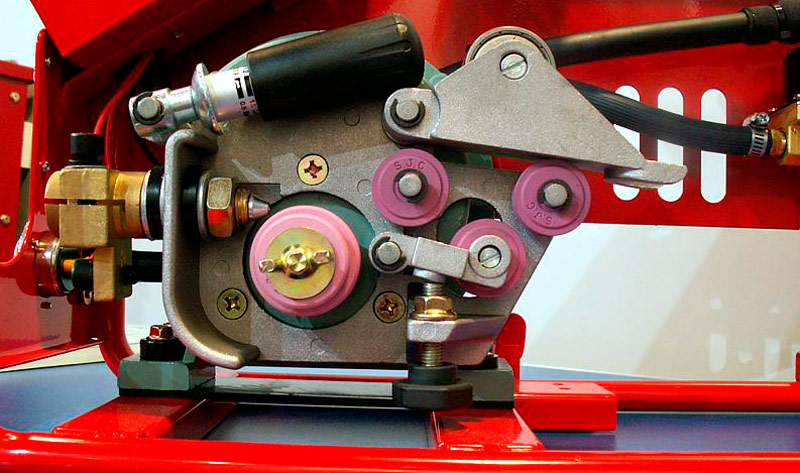

Sleeves can be from 2 to 8 m long. The larger the hose package, the more maneuverable the welder. But in this case, a reliable four-roller feed mechanism is required.

Four-roller semi-automatic wire feed mechanism.

It is also important to ensure that the channel does not twist, otherwise the wire will begin to “skid”. For work in the garage or in the courtyard of a private house, 2-3m is enough. In the workshop, it is desirable to have a stock of 4-5 m.

Cooling method

If you collect the frames of greenhouses, arbors, doors, gates, then a lot of time is spent on the preparation of parts, cleaning, pruning. The length of the seams in such structures does not exceed 10 cm.There is enough burner with an air type of cooling, which will have time to cool down while other work is underway. With continuous welding with long seams, water cooling is necessary, otherwise productivity will suffer.

Burner connector

There are non-built-in burners that cannot be disconnected from the device. In the case of separate execution, the EURO connector is most often used, which is also labeled KZ-2. If you have a semiautomatic device with such an input, then any burner with a Euro plug is suitable for you.

Euro connector for connecting the burner to the semiautomatic device.

On some models, there is a PDG-309 connector. Then you need to look for just such a designation to replace the snap.

PDG connector 309.

Type and size of wire channel

The type of channel is steel and teflon. The first is used for solid and hollow wire when welding stainless steel and ferrous metal. The second is suitable for threading aluminum wire and welding aluminum and its alloys. The diameter of the channel is selected based on the cross section of the wire and is 0.6-1.6 mm.

Ergonomics

The more natural the burner falls into the hand, the less the welder will get tired during prolonged work. To do this, there should be cutouts on the handle, the start button should be located below and exactly under the index finger, the front extension is designed to prevent slipping. Rubber inserts contribute to a firm grip.

Ergonomic welding torch handle for semiautomatic device.

Rules of operation and maintenance

To make it convenient to cook with a heating pad, its channel should not be twisted or assembled into loops. This makes it difficult to wire. The collector mouthpiece is selected according to the diameter of the additive supplied from the coil. Over time, its inner hole is developed and the wire begins to “walk”, which makes it more difficult to control the formation of the seam. In this case, the mouthpiece is changed to a new one.

The torch nozzle directs the shielding gas exactly to the weld zone. Gradually, it becomes fouled with scales inside, which need to be cleaned. Metal splatter sticks from the outside, so it is recommended to apply oily sprays that reduce adhesion (create a film on the surface of the gander and nozzle). The cable channel is prone to accumulation of debris and technical grease from the wire, so once a year it needs to be cleaned, for which special devices are released.

The best torches for welding semiautomatic devices

If you do not have a semiautomatic device with an integral connection of the cable channel to the body, then such a burner can be replaced with a more convenient one. To purchase, look for a product with a EURO plug designation. It is universal and fits any device with the same connector. Buying equipment of the same brand as your semiautomatic device is not necessary.

150-180 A burners

If a welding semiautomatic device is used to connect metal with a thickness of 0.8-7.0 mm, then a torch designed for a current strength of 150-180 amperes is enough.

MIG-150 BRIMA

Semi-automatic burner from a German manufacturer. Equipped with an ergonomic handle with several cutouts that fit well in the palm of the welder. The cable channel can accept wire from 0.6 to 1.0 mm. The sleeve length is 3 m, which is enough for a stationary welding station in the workshop. If cooked at a current of 150 A, then the on-time will be 60%. The Euro connector is equipped with a prominent embossment, which facilitates the connection to the welding machine. The accessory is cooled by air from the outside and gas from the inside.

The torch is notable for an elongated nozzle, which is suitable for welding on the forward and reverse polarity (less heated). Also, the angle of the gander is minimal, which allows it to be inserted into pipes and welding in hard-to-reach places.

Foxweld 6068 MIG-15

This is a burner from an Italian manufacturer. It is suitable for semi-automatic welding in both shielding and active gas environments.Implemented air cooling. The maximum current is permissible 180 A. In this case, the PV will be 40%. The accessory is compatible with 0.6-1.0 mm diameter wire. But the burner weighs 2.4 kg with a cable channel, so at a height you will have to hold it with your second hand so as not to delay.

The model is notable for a sleeve length of 5 m. This is beneficial when working with large structures - you will need to move the device less often. The increased mobility of the welder allows you to quickly switch from one product to another and even work alternately on two welding tables.

AURORA 12017 PRO MIG 15 AIR COOL

This burner has a wide rubber pad on top to prevent slipping out of your hands. The trigger location is separated so that other fingers do not move out there. The hose package is thinner than other manufacturers and lighter. The channel length is 3 m, and the maximum current is permissible up to 180 A.

Judging by the reviews of welders, this model is quite comfortable for holding and working for 6-8 hours every day. It is also the most affordable. If you have a welding semiautomatic device from a famous brand that needs to replace the torch, then you can save money without losing quality.

FUBAG 38440 FB 150

This is a premium quality burner from a German brand. It has a sleeve length of 3 m and passes a wire with a diameter of 0.6, 0.8 and 1.0 mm. You can cook it with a maximum current of no higher than 180 A, otherwise it will overheat and melt. Two embossed rings are provided on the nozzle for convenient tip removal.

The burner is expensive, but very comfortable. Welders appreciate it for ergonomics. If you need to cook for 6 hours every day, then your hand will be less tired with it. The button is pressed very easily with one finger. Rubber pad on top prevents slipping in hands.

VIKING 95588016 MIG 15AK-4m

At the end of the rating, we placed a burner from an Austrian brand. She has an optimal operating current of 150 A, at which the turn-on time is 60%. If necessary, then for a short time it is possible to carry out welding at 180 A, but with longer breaks for cooling. Sleeve length of 4 m increases the mobility of the welder. A burner with a channel of 2 kg weighs. It differs from most other models by the location of the rubber insert at the bottom, which prevents the fingers from slipping.

Such a product is suitable where you often have to change position and cook vertical, ceiling and corner seams. To prevent the cable channel from bending, long spring inserts are provided at the entrance to the burner and in front of the Euro connector.

The best burners for 200-250 A

When it is required to weld parts with a thickness of 10-20 mm, it is necessary to increase the current strength on a semiautomatic device. Accordingly, a burner is needed with a large current indicator. Here is a ranking of the best models of this level.

MS 24 Svarog ICT2698

MIG torch for welding in carbon dioxide and argon mixtures. With a MIX gas, a current of 220 A is permissible, with a carbon dioxide of 250 A, in both cases the PV is 60%. The hose package, judging by the reviews, is quite flexible. Its length is 3 m. The burner is designed for air cooling. You can thread the wire from 0.8 to 1.2 mm. Total item weight 2.7 kg. The tip is massive and durable. But a long lead prevents the control of the weld pool.

This model is interesting by the presence of anti-slip pads on top and bottom on the handle. This design is especially relevant for work on high structures (so as not to drop) or in hot conditions (outdoors in the summer). The torch is also notable for a gander covered with copper, which reduces the amount of sticking spatter from welding.

BRIMA MIG-250

Further burner from a German brand. According to reviews, customers like the product at an affordable price. The handle has no rubber pads, but there are protrusions under the fingers. The anatomical shape relieves tension on the arm. The cable length is 3 m. The wire diameter is 0.8, 1.0 and 1.2 mm. The maximum current is not more than 250 A. With this indicator, you can cook continuously for 6 minutes, and then let it cool for 4 minutes.

Pay attention to the powerful spring at the base of the connector and handle. She does not allow a crease of the channel with a strong bend. The wire will feed continuously.The wires leading to the buttons (loop) will remain intact, despite frequent kinks in the sleeve.

AURORA 12027 25 AIR COOL

Reliable torch for a semiautomatic device with the checked quality. Allows you to work with wire up to 1.2 mm in diameter. It has good heat dissipation and supports semi-automatic welding with a current strength of 230 A. The anti-slip pad is on top of the handle. The gander is sprayed with chrome to reduce adhesion of the spray. Euro-connector with high edges is easy to insert into the socket on the semiautomatic device.

The model is notable for a cable channel length of 5 m. Thanks to this, the welder can walk around a large product without transporting an apparatus with a cylinder. With such a sleeve it is practical to weld metal structures to our construction site.

FUBAG 38443 FB 250

The product from a German manufacturer completes the rating of powerful burners for a semiautomatic device. The burner is extremely convenient due to the anatomical shape and two rubber inserts. The gander angle is optimal for minimal bending of the wrist. The series is designed for a maximum current of 230 A. You can install a thin wire of 0.8 mm for welding bodies, and a thick wire of 1.2 mm for connecting workpieces with a cross section of up to 20 mm.

The burner has a very sensitive start button. This helps when the semiautomatic device is used to assemble critical structures where multiple tacking is required. Pulling the trigger 1000 times a day does not tire. A flexible docking element at the base provides bending torch mobility for welding in different spatial positions.