MDF or particleboard: which is better - a comparison of the characteristics of materials

The woodworking industry produces both completely natural and artificial materials. Among the latter, MDF and particleboard stand out, but what is better to use, it will not work right away - it depends on what needs the material will be used for. In this article we will compare these materials by such parameters as: environmental friendliness, durability, water and fire resistance, processing complexity, and also cost.

Content:

- What is chipboard and MDF board

- Strength and density

- Which material is more environmentally friendly chipboard or MDF

- Which plate is more resistant to moisture particleboard or MDF

- What is more difficult to process chipboard or MDF

- Chipboard and MDF decoration options

- What material is more fire resistant chipboard or MDF

- Fastener Retention

- What is cheaper than chipboard or MDF

- Final Comparison of Particleboard and MDF

What is chipboard and MDF board

The manufacture of MDF and particleboard is carried out using similar technologies and at first glance, it is quite difficult to find external differences between them. But if we examine in more detail their production in general and the raw materials used for it in particular, then the differences that affect the field of application of the materials will be quite significant.

Chipboard - manufacture and use

The raw materials for the production of chipboard sheets are wood sawdust. The production process consists in mixing the raw material with a binder, which is used as a variety of formaldehyde resins and pressing the resulting mass.

Chipboard plates.

When the base is ready, the outer decorative layer can be glued onto it, resulting in such subspecies of the material as chipboard (laminated particleboard) and chipboard (lined chipboard). In the second case, the paper is “coated” with glue paper, which in many respects loses to the laminate, but is more attractive at a price.

Plates of chipboard.

The areas of application of chipboard are the production of cabinet furniture, packaging of goods and various construction works.

MDF - manufacture and use

Technologically, the production of MDF boards (fiberboard) resembles the manufacture of paper - at least the preparation of raw materials up to a certain point is done the same.

To create MDF, not whole chips and sawdust are used, but crushed to the state of individual wood fibers. This means that any waste from the woodworking industry can be used as raw material.

At the first stage of preparation of raw materials, it is ground to the size of crumbs, after which it is cleaned with hot steam, which is supplied under pressure. After that, the cleaned and moistened mass is fed to the defibrator, which finally grinds its particles to the minimum size.

The last stages of production are drying of raw materials, mixing the entire mass with special resins and hot pressing into finished plates. The result is a material that in many respects is not inferior to a natural solid wood. He found the main application in the furniture industry, since in other industries it is more profitable to use cheaper analogues.

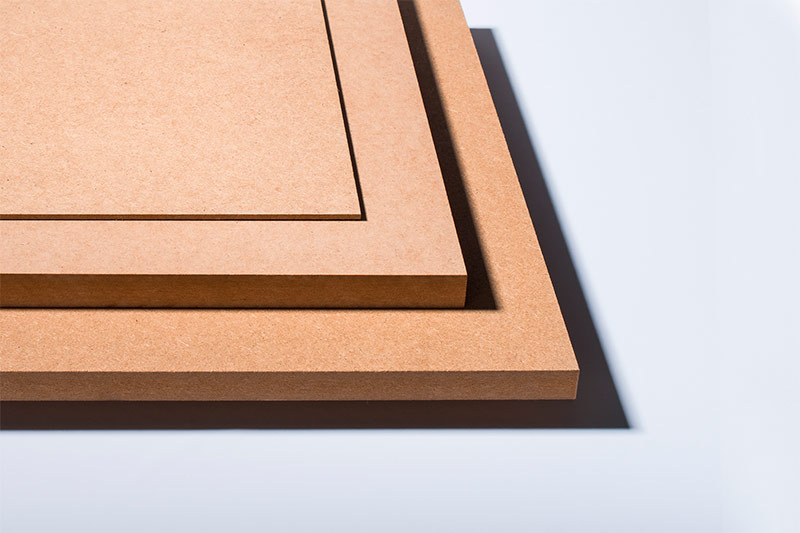

MDF boards of various thicknesses.

In more detail about all the characteristics of materials can be found only by comparing them with each other. This will clearly show how the chipboard differs from MDF and what is better to choose for certain tasks.

Strength and density

This parameter is directly affected by the raw materials used in the production. Since chipboard is made of whole chips, which can be arranged in random order, its average density will be different, and in a fairly large range - from 350 to 650 kg / m³. Moreover, there are several varieties of particleboard, which just differ from each other by the density of pressing and the ratio of feedstock to the amount of binders.

In the production of MDF, the raw materials are crushed to an almost uniform state, therefore, it does not have such large differences in density - the average figure is in the range 720-870 kg / m³.

As a result, the strength of MDF is significantly superior to chipboard, and in some cases, even certain varieties of solid wood.

Which material is more environmentally friendly chipboard or MDF

According to this indicator, all the cones go to the share of chipboard, since in its production formaldehyde resin is used as a binder. Besides the fact that these compounds are simply harmful to human health, they also actively evaporate from the surface of the stove. Evaporation rate is affected by temperature.

According to the environmental safety class in Europe, chipboard sheets are divided into two types - E1 and E2, but if this material is manufactured according to domestic standards, then all its parameters are governed by a single GOST. This does not allow for an accurate classification, the need for which is long overdue, since E2 is prohibited for use in the manufacture of children's furniture, and in some countries it is generally discontinued.

The production technology of MDF provides for the use of the dry pressing method, which is done under high pressure and temperature. A binder is also used here, but urea resins less harmful to humans are used in its quality. In fairness, it should be noted that they also contain formaldehyde, but a small amount of it, and in the manufacture of MDF resins are additionally modified with melanin, which significantly reduces the already small amount of fumes.

Emission of harmful substances contained in MDF is significantly lower than in particleboard, therefore, in terms of environmental friendliness, fiberboards are superior to particleboard.

Which plate is more resistant to moisture particleboard or MDF

In its pure form, a chipboard plate does not tolerate moisture very well - when wet, its base actively begins to absorb water and can increase its volume by about 30%. The chipboard is slightly better with moisture resistance - the laminate by itself is not afraid of water and is able to resist getting wet for a long time, therefore it is often used to create budget class worktops. He proved himself to be excellent, but with damage to the outer coating, all the flaws are fully manifested - if water leaks to the stove, it will be actively absorbed.

Chipboard wetted.

Since MDF itself is a more dense material, even without an outer coating it resists wetting well and even if it enters water, it can hold its shape for several hours, which is even superior to some types of natural wood.

What is more difficult to process chipboard or MDF

As in the case of density, the raw materials used in the production are responsible for this parameter. Since the chipboard consists of whole chips, it is very difficult to fine-tune - all cutting lines that are not straight can lead to the formation of chips.

Since finely dispersed raw materials are used to create MDF, this affects the structure of the material, which is more uniform and dense. This material easily tolerates any kind of processing - cutting, curly cutting or milling.

Milled MDF.

Due to the ease of processing, MDF is widely used in the manufacture of carved facades, platbands and moldings used in furniture production. According to this, MDF prevails.

Chipboard and MDF decoration options

In the case of chipboard and fiberboard, decoration means finishing these materials with additional layers of laminate or veneer. If in the second case there are usually no problems, then decorating with a laminate or paper with chipboard can be difficult. They are caused by the initially rough surface of the plate - if a thin film is glued to it, then all the tubercles and veins will be visible on it. As a result, all chipboard boards are sanded and only then can film or paper with a pattern be applied to them.

MDF sheets are initially devoid of such drawbacks due to their density - immediately after manufacture they are suitable for applying any decorative coating.

What material is more fire resistant chipboard or MDF

Both materials in their pure form are combustible, and MDF in this case even loses somewhat, since it ignites more easily and faster than particleboard. To give the materials refractory properties, they are additionally treated with anti-foams, but in any case, the combustibility of MDF is higher.

Fastener Retention

Particleboard has long gained fame as a “disposable” material - the furniture assembled from it is very difficult to disassemble without loss, move it to another place and put it back in place. The reason for this is the fastenings, which, even in the case of perfectly even screwing and unscrewing the screws during reassembly, at best, will hold much weaker. Worse is the more likely outcome - the attachment point will simply crumble and you will have to additionally process it with glue or use screws of a larger diameter.

As a result - if there is a choice, then you need to take furniture from chipboard, in which not screws are used as fasteners, but bolted connections with wide washers. If they already break, then you won’t have to puzzle over the possibility of restoring the fasteners.

MDF, due to its density, freely tolerates repeated assembly-disassembly - in this, again, it is not very different from natural wood.

What is cheaper than chipboard or MDF

By this criterion, particleboard will give odds to any material. Of course, you can take into account the varieties and quality of the external coating and its finish, impregnation with water and fire-resistant compounds, but in general, the difference in cost between MDF and particleboard will be about 50%.

If you compare the plates with a coating of good plastic, enamel or natural veneer, the difference will be even greater, but here you already have to choose between the desire to save money here and now, when buying or in the future - on operation.

Final Comparison of Particleboard and MDF

|  | |||||||

|---|---|---|---|---|---|---|---|---|

| MDF | Chipboard | |||||||

|

|

|||||||

| Strength and density | 720 - 870 kg / m³ |

350 - 650 kg / m³ |

||||||

| Environmental friendliness | higher |

below |

||||||

| Moisture resistant | more stable |

less stable |

||||||

| Processing difficulty | withstands any kind of processing |

may break during processing |

||||||

| Decoration Features | easier to decorate |

more difficult to decorate |

||||||

| Fire resistance | less fire |

more fire resistant |

||||||

| Fastener Retention | good |

bad |

||||||

| Plate cost | high |

50% lower than MDF |

||||||

When you know every difference between particleboard and MDF, what is better to choose and in which case - it becomes more clear. If MDF is more associated with the middle price segment, then chipboard takes the lowest possible price and the possibility of use in auxiliary and one-time jobs, for which it is at least impractical to use expensive materials.

It is also necessary to consider the possibility of combining materials - if you make a frame from particleboard and use MDF for exterior decoration, you will get a combination of good price and acceptable quality.