8 best soldering irons for soldering polypropylene pipes

Our rating of the best machines for welding polypropylene pipes, based on their characteristics and user reviews, will help to buy a tool with a long service life and good quality seams. The information given will tell you which soldering iron to choose in form and power, depending on the tasks ahead.

What soldering iron for polypropylene pipes is better to buy

All devices for welding plastic pipes have heating elements and matrices, where the ends of the pipe and fitting are placed. In them, the workpieces are heated and connected to each other, creating a tight circular seam in a matter of seconds.

The main parameters for selecting a tool are:

- Power. It varies from 600 to 2000 W and affects the heating rate of plastic and productivity - the higher the indicator, the faster it will be able to complete the work.

- The number of nozzles and their diameter. Pipes of what diameter can be connected by means of a welding machine depend on this.

- Temperature adjustment. Facilitates the adjustment when working with polypropylene from different manufacturers, in which the melting temperature ranges from 220 to 260 degrees. Improves the use of a soldering iron depending on the season - especially in winter, when the plastic is colder.

But for various types of work it is important to choose the right form of a soldering iron. There are only two of them.

Xiphoid devices

They have an elongated plate, in the form of a wide sword, on which nozzles are bolted. The temperature from the plate is transferred to the matrix. These soldering irons are also called irons because of the shape of the heating element.

Such models are more designed for stationary work on the table. The welding machine is good for working in uncluttered places where it is convenient to crawl with the xiphoid structure. Even due to the ability to install several pairs of matrices at once, it is convenient for welding polypropylene pipes of different diameters.

Cylindrical apparatus

This type of soldering iron for polypropylene pipes has a heating element in the form of a cylinder. Nozzles are put on it from the end and are pressed by bolts along the edges included in their design. The degree of remoteness of the matrix from the edge of the cylinder is not limited by anything (there is no specific landing hole), so you can set any distance for soldering pipes near the wall itself. The tool body continues its cylindrical shape, which makes it much more compact than other models.

Such welding machines for plastic pipes are the best in the case of complex decoupling of communications: branching in the boiler room, connecting underfloor heating to the collector, soldering in narrow niches, etc. Thanks to the thin form, the device is convenient to travel to limited places and turn it in different directions to perform pipe joint already connected by one side to the system. But if desired, they can work stationary, for which the manufacturer provides a small hinged plate-stand.

The best machines for welding polypropylene pipes with power up to 1000 W

With this indicator, welding machines of both forms (xiphoid and cylindrical) are produced. Their feature is one heating element inside, because of which the heating of the matrices and welding of pipes occur slowly.

In terms of equipment, everything depends on the cost: very simple models have only a light indication, a toggle switch and a temperature regulator. The more expensive ones are equipped with a display and accurately support the settings electronically.The rating of soldering irons for soldering polypropylene pipes with power up to 1000 W will help you choose the right tool.

|  |  |  | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inforce 03-24-01 | Gigant GPW-1000 | Elitech SPT 1000 | Caliber SVA-1000T | |||||||

| Power, W | 1000 | 1000 | 1000 | 1000 | ||||||

| Weight, kg | 3,5 | 1,3 | 0,9 | 1,0 | ||||||

| Maximum diameter of welding, mm | 63 | 63 | 32 | 32 | ||||||

| A type | apparatus | apparatus | soldering iron | soldering iron | ||||||

| Heater shape | xiphoid | xiphoid | cylindrical | cylindrical | ||||||

| Temperature regulator | digital | mechanical | mechanical | mechanical | ||||||

Inforce 03-24-01

Premium model from a Russian manufacturer, equipped with a digital display and electronic temperature control. Management is carried out by four buttons on the right sidewall of the case. The iron has three holes for fixing nozzles.

+ Inforce Pros 03-24-01

- You can set the temperature in the range from 0 to 300 degrees and it will always report the current indicator.

- Sturdy stand with U-shaped tube.

- Two bolts for fixing the nozzles are supplied, so you can install two pairs at once.

- Relatively lightweight model, convenient for transportation and work on outstretched arms.

- When overheating, emits a sound signal.

- It remembers the last temperature set and, when turned on again, heats up to it.

- Good nozzle coverage - plastic does not stick.

- Six pairs of couplings with a diameter of 20 to 63 mm and a suitcase are included.

- Cons Inforce 03-24-01

- If you need to hold the soldering iron by the handle for welding in place, then this is inconvenient because of its short length - more suitable for stationary work on the table.

- To put the device in a case, you have to remove all the nozzles - with those left on the sword it does not fit.

- The short cord spins quickly.

- The change of nozzles is carried out by a hexagon, which slows down the process.

- The vertical bracket from the stand is connected to the horizontal tube with only three tacks, so it can fly off over time.

Conclusion. A good apparatus for soldering plastic pipes from various manufacturers. Electronics maintains the set number of degrees with an accuracy of + -5, which will help not burn the ends and make smooth joints without sagging. Such a soldering iron is the best for leisurely welding where the aesthetic appearance of the finished communications is very important.

Gigant GPW-1000

A simple soldering iron from a Russian manufacturer with a power of 1000 watts. It has a mechanical temperature controller, two diodes to indicate operation, a rectangular stand on the table. The heating element has two openings for installing nozzles with different distances from the edge.

+ Pros of the Gigant GPW-1000

- Temperature adjustment from 0 to 300 degrees for different plastic.

- It is equipped with a hexagon and a screwdriver for changing dies.

- The rubberized handle with corrugations is well suited for working in hot weather.

- Quickly gaining operating temperature - 2-4 minutes.

- The lightweight 1.3 kg design makes it easy to fit pipes under the ceiling.

- There is a capacious case for transportation.

- The base already has holes for fixing to a table or stool.

- Cons Gigant GPW-1000

- A bad stand, very flimsy (made of tin) - if it is screwed to the table, the soldering iron will still wobble, as there is a strong backlash in the bracket.

- The Teflon layer is thin - soon after the purchase and the first joints, plastic begins to stick.

- Due to the wide sword, it is inconvenient to solder in place.

- For some users, protection against overheating stops working and the heater melts.

- In the case there are clamps only for large nozzles, the rest hang out during transportation.

Conclusion. The welding machine is very simple and not designed for complex tasks. For that, its price is one of the lowest. It is perfect for personal use when installing a heating system or water supply. Nozzles from 20 to 63 mm allow the installation of water pipes of any diameter in this range.

Elitech SPT 1000

Compact rod soldering iron for polypropylene pipes with a diameter of 16 to 32 mm. It has a power of 1000 watts and a mechanical temperature regulator. There is a metal stand in the form of a small hinged plate.

+ Pros of Elitech SPT 1000

- A lightweight soldering iron weighing 0.9 kg is convenient for long manipulations in manual mode.

- Holds steady when installed on a stand.

- It lies well in the hand due to cutouts under the fingers.

- It is rapidly gaining temperature.

- It can work up to 6 years with periodic use in the country and in the house.

- The place of holding does not slip in the hand.

- The kit comes with tools for mounting nozzles.

- Especially suitable for joining pipes overhead.

- Cons Elitech SPT 1000

- The case is very small and another nozzle can hardly fit there.

- It is difficult to set the desired temperature - on 2-ke the plastic heats up for a long time, and on 3-ke it burns.

- After 20-30 joints, plastic begins to adhere to the Teflon coating.

- No nozzles for working with large pipes (from 40 mm and above in diameter).

- If there is a large amount of work to be done in one day, then breaks will be required for the heater to cool down.

- There are no holders for nozzles - during transportation they roll around the box and ring.

- With the clutch on, the device does not fit on the cylinder - after each use, the nozzle must be removed to fold the soldering iron.

Conclusion. Such a welding machine is convenient for self-assembly of a warm floor in a private house. It is easy to crawl under a compact rod under other communications and make docking in place. The coupling with a diameter of 16 mm is optimal for wiring narrow tubes that are close to each other.

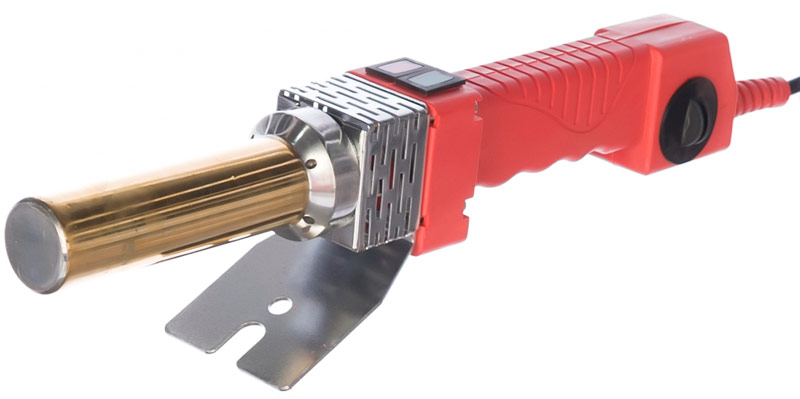

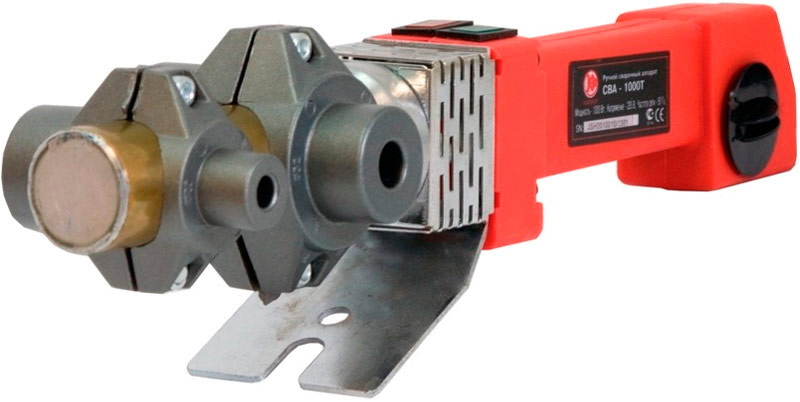

Caliber SVA-1000T

Rod soldering iron from the Russian manufacturer "Caliber" with three shoe nozzles and a power of 1000 watts. In the upper part it has two diodes for indicating the network connection and reaching the set temperature.

+ pros

- The device is not bulky, so it is easy to get to solder in a niche behind the toilet or under the bath.

- Does not overfill plastic when set up correctly.

- Quality nozzles with a thick layer of non-stick coating.

- Heats up quickly.

- Steadily keeps on a support.

- Long service life in case of use at home and in the country.

- Minuses

- The temperature controller hooks on clothes and other objects - as a result, the settings go astray, and a person may not even notice this and warm the following workpieces for a long time or burn them.

- Short power cord.

- Nozzles sometimes come scratched (there is no individual packaging for each), which initially spoils the non-stick properties.

- The case has wide gaps through which the hexagon can fall out.

- The error in maintaining the temperature at 15 degrees.

- The first time after purchase and inclusion can smoke, then passes.

Conclusion. This is the best apparatus for soldering polypropylene pipes in your kitchen or bathroom to perform wiring instead of steel communications. It will be convenient for them to work even for a beginner. The advantage of the model is its weight of 1 kg, so keeping the soldering iron on the weight will not affect the quality of the seam.

The best machines for welding polypropylene pipes with a capacity of more than 1000 watts

Welders in this category have a capacity of 1500 to 2000 watts. Such equipment is characterized by accelerated heating, which increases productivity - in the same time, you can make more joints. As for the tightness of the seam, there is no difference in quality with less powerful models.

These soldering irons for polypropylene pipes are equipped, as a rule, with two heating elements, which can be switched on simultaneously or alternately, which allows you to more finely choose the temperature and heating time, as well as electricity consumption. Such models are richer in configuration and are better suited for professional use.

|  |  |  | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inforce 03-12-02 | PATRIOT PW 205 | Elitech SPT 1500 | STURM TW7218 | |||||||

| Power, W | 1700 | 2000 | 1500 | 1800 | ||||||

| Weight, kg | 1,7 | 1,3 | 5,4 | 1,1 | ||||||

| Maximum diameter of welding, mm | 63 | 63 | 63 | 32 | ||||||

| A type | apparatus | soldering iron | soldering iron | soldering iron | ||||||

| Heater shape | xiphoid | xiphoid | xiphoid | cylindrical | ||||||

Inforce 03-12-02

The device with a power of 1700 watts with two toggle switches, allowing you to work in one of three modes: 700 W, 1000 W, 1700 watts. It is supplied with a bracket with horizontal placement on the table or fixation in an upright position and clamped vice.

+ Pros of Inforce 03-12-02

- Comfortable rubber grip - keep comfortable.

- Ample opportunities for choosing the temperature as toggle switches and thermostat from 0 to 300 degrees.

- Fast heating of heating elements.

- Good luggage capacity.

- It is completed with a tape measure, a screwdriver, a pipe cutter and gloves.

- All nozzles in the case are fixed and do not hang during transportation.

- Six matrices for pipes with a diameter of 20 to 63 mm.

- The pipe cutter will completely cope with its task and you will not need to buy anything extra.

- Good surface coverage of nozzles.

- Cons Inforce 03-12-02

- A bulky case, due to which it is inconvenient to climb in place to close the communication circuit.

- Not the easiest model and if you hold it with your hands, the master will quickly get tired.

- There are nozzles with chips, but this is rare.

- The suitcase is flimsy and requires careful handling, otherwise it quickly deforms.

- The heater is attached to the body through the bracket, and the cap of the bolt prevents the apparatus from being placed on the stand.

- At start, the set temperature of 260 degrees skips and overheats the fitting, so first you need to set 150 degrees and then raise it.

Conclusion. This is the best soldering iron for polypropylene pipes due to its very high-quality nozzles. The Teflon coating is thick and long eliminates traces of plastic on the matrix. The device is well suited for frequent use at facilities with a large amount of work.

PATRIOT PW 205

2000 W xiphonic soldering iron with three holes on the heater for fixing the matrices with different distances from the edge. It is equipped with two toggle switches for power selection and a temperature controller in the right side of the case. Equipped with an X-shaped stand.

+ Pros of PATRIOT PW 205

- Heats up very quickly and stably keeps the temperature set.

- Flat pipe cut with scissors from the kit.

- Gloves from a set with thermal insulation for twisting uncooled nozzles.

- Hardy sole of the iron - does not melt when overheated.

- The thermostat pretty accurately maintains the set temperature.

- Light weight 1.25 kg is optimal for working on outstretched arms.

- Six nozzles included.

- There is a tape measure and a metal case.

- The choice of power from three options with tuning through toggle switches.

- Cons PATRIOT PW 205

- Nozzles are constantly untwisted.

- The body of the soldering iron is made of very thin metal - careless movement and you can put a dent.

- The matrix for the 63 mm pipe is not inserted in its intended place - it abuts against the body.

- Scissors in the kit are weak - they break after 10-20 cuts.

- The place of fixing the handle to the body must be strengthened with bolts, otherwise it will first bend and then fall off.

- The stand is flimsy and staggering.

- Burns paint on the body next to the heating elements.

Conclusion. This machine for soldering polypropylene pipes is well suited in cases where speed is a priority. The power of two heaters in total is 2000 W, so heating the end of the tube and fitting will take a minimum time and in one day of work it will turn out to make a large number of joints.

Elitech SPT 1500

The soldering iron has a power of 1500 W and a set of matrices for pipes with a diameter of 20 to 63 mm. The front of the iron is pointed to improve access to bottlenecks.

+ Pros of Elitech SPT 1500

- Heats up quickly to the set level.

- No traces of plastic remain on the surface of the nozzles.

- The compact shape of the heater makes it easier to insert the tool into a niche or under other pipes.

- The tool kit in the kit is not disposable.

- Three hexagonal bolts for installing several pairs of nozzles at once and quick installation of pipes with different diameters.

- The support is cross-shaped and stable, there is a side clamp on the thread for fixing in an upright position.

- The level is equipped with three cells to control all planes.

- Cons Elitech SPT 1500

- A short cord requires a carrying connection - when working at height, it pulls down due to weight.

- A case made of very thin metal - the lid is unbent, the latches hold poorly.

- During transportation, all contents fall into one pile.

- Scissors can cut pipe diameters up to 40 mm only.

- Gloves are cheap and come apart quickly.

Conclusion. A great option for a master with field work. The kit includes everything necessary for installing water supply or heating: tape measure, pipe cutter, level, gloves. The pointed heater will facilitate manual operation for docking in hard to reach places.

STURM TW7218

It has a power of 1800 watts with one mode of operation and temperature control from 0 to 300 degrees. The cylindrical heating element is coated with a non-stick coating to stay clean longer.

+ Pros of STURM TW7218

- Very lightweight 1.1 kg model for comfortable work in all spatial positions.

- The case is painted with powder paint and retains its normal appearance for a long time.

- Thick aluminum nozzles.

- Heats up in 2-3 minutes.

- Clear on and off - the device does not overheat and can be soldered for a long time.

- The outlet of the network cable from the case is equipped with a seal so that the wire does not break for a long time in this place, which is one of the most common failures in other soldering irons (they close it there).

- Cons STURM TW7218

- The designation on the thermostat does not correspond to reality and you need to adapt yourself to remember in which position the device heats better for plastic of different thicknesses and brands.

- The soldering iron is easy to turn over if accidentally hurt by hand or foot.

- Nozzles are mixed and churned during transportation - it is better to wrap them with cloth.

- There are only 4 matrices in the set.

- There are few original nozzles on sale - if these peel off, you will have to buy expensive imported ones.

- The side for putting on the pipe is slightly larger than the standard size, so you have to pull it with difficulty and you need to get used to it.

- A very small instruction without a job description - a beginner will need to look for additional information.

- The heating cylinder hangs - you need to periodically tighten the mount.

Conclusion. Thanks to the compact form, short rod and high power, it is easy for them to wiring from the boiler house around the house, bring the supply from below to the heating radiator, power the boiler from the back and connect the circulation pump to the system. The presence of a nozzle for a diameter of 16 mm allows you to use it when installing underfloor heating.

The selection of goods was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.