Types of siding for house sheathing

Manufacturers offer various types of siding - basement, ceramic, steel, wood, cement, aluminum, copper. Siding today has gained immense popularity. It is used for cladding private houses, office buildings, commercial premises, etc. The material has won such recognition due to its qualities - durability, strength, attractive and neat appearance.

What is siding and its advantages

Siding - these are separate panels that are very conveniently fastened together. Externally, siding trim is similar to plank cladding. Each panel has a latch lock and a perforated edge for nails. Siding stripes come in different sizes. Length, as a rule, varies from 2 to 6 meters, width 10-30 cm, thickness up to 10 mm.

The siding profile is performed in two versions: “herringbone” (single fracture) or “shipboard” (double). This does not affect the quality of the material, and a profile is selected only on the basis of personal preferences. Siding texture most often imitates natural wood. For protection against shock, scratches and corrosion, use a special polymer coating or paint.

Siding retains its qualities and original appearance for several decades. It perfectly protects the building from the effects of atmospheric phenomena. This is a very lightweight, easy-to-use material that looks great in any landscape. In addition, the siding is environmentally friendly and easy to clean. It is easy to clean and does not require periodic painting, unlike wood materials.

All types of siding for cladding are very easy to install and can be cladding on your own. Installation of siding does not require special skills, including thorough preparation of the wall surface. On the contrary, it helps to hide many irregularities and other flaws.

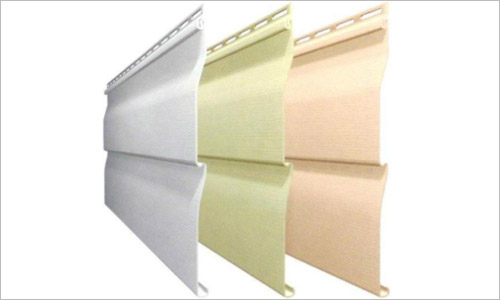

Types of Vinyl Siding

Vinyl siding is made from polyvinyl chloride. It represents solid stripes, which are also called panels. Each panel is a monolithic sheet, which is given the desired shape.

Vinyl siding does not crack, does not crack, does not rot and does not represent any interest for insects, unlike wood materials. The advantage of siding is that it does not support the combustion process, but simply melts under the influence of high temperatures.

PVC panels are used both for the construction of new buildings and for the decoration of old houses. Often, simultaneously with the installation of the siding, the building is insulated, since the insulation is very convenient to lay in the crate space.

Vinyl siding is available in standard sizes:

- length - 3000 mm, 3660 mm, 3730 mm, 3850 mm;

- width - 205 mm and 255 mm;

- thickness - 1.1 mm and 1.2 mm.

Advantages of PVC panels:

- low flammability;

- environmental Safety;

- resistance to atmospheric agents and chemicals. Well established in the conditions of the increased humidity and the moderate acid or alkaline environment. Does not crack, does not warp in the sun and does not rot;

- operating temperature range 0t -50 to +50 degrees. Under such conditions, it does not burst and does not change the initial shade;

- ease of operation: it is easy to clean with a hose and does not require additional painting throughout the entire service life;

- a huge selection of colors and shades;

- Does not interfere with ventilation at home, as it does not seal the walls tightly;

- openings in the lower edges of the panels prevent condensation. This protects the insulation material and wooden structural elements from decay;

- due to the possibility of insulation, it saves money on heating the house;

- low price in comparison with other types of facing materials;

- high reliability, which avoids costly and energy-consuming repair work.

- the texture of the outer surface of the panels can be smooth or rough, imitating natural wood.

There are two ways to install PVC panels: horizontal and vertical. Vertical siding is used relatively recently. In another way it is called spotlights.

Spotlights are used for exterior decoration. Basically, it is stacked with the roof lining instead of the plastic lining that was used previously.

Today on the market there are about 15-20 siding color options. All of them can be divided into three main groups:

- white

- pastel;

- colored.

Most often, you can find siding in pastel shades. This type is optimal in terms of price, visual and operational qualities.

Bright colors siding also has a very attractive appearance. But at the same time it costs twice as much as usual material. This increase in price is associated with the need for the addition of expensive substances that prevent burnout in the sun.

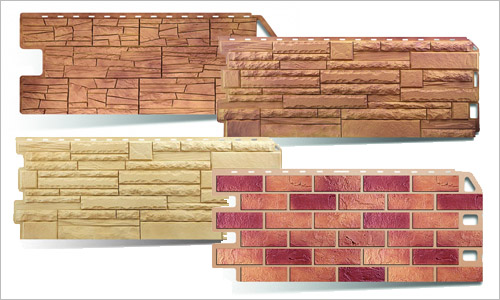

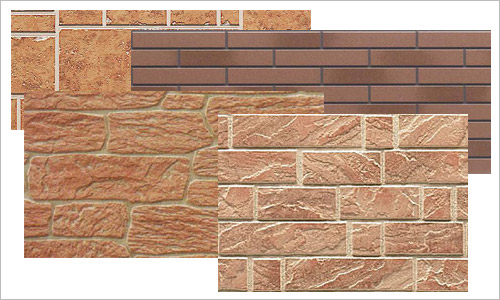

Basement siding and its types

Basement siding - a kind of vinyl panels that are used specifically for finishing the basement. Such siding has higher strength characteristics. The basement is much more susceptible to destructive factors than the rest of the house. In the summer, it is very hot from sunlight and asphalt. And in winter it is in conditions of high humidity due to sticking snowdrifts.

The variety in the design of the basement siding is much greater than that of simple vinyl panels. Of the many colors and textures, you can always choose the most optimal option. Most often models of basement siding imitate alternative natural facing materials: wood, stone, brick, etc.

The panels are used for finishing both external and internal surfaces. Basement siding is used for:

- wall cladding of the house and the foundation;

- creating a building facade with a ventilation system and a layer of insulation;

- creating the original design of garages, baths, fences, arbors, etc .;

- decoration of walls indoors for various purposes.

Among the many advantages of basement siding, the most important ones can be distinguished:

- moisture resistance (makes it possible to use in saunas and pools);

- lightness (perfect for covering ceilings);

- quick and easy installation (allows you to use for the assembly and reconstruction of temporary exhibition stands).

Types of Metal Siding

Aluminum siding. This material is suitable for decoration of residential premises, offices, industrial buildings. Due to the lightness of the panels (only 1.7 kg per square meter), safe use in multi-story buildings is possible. This type of siding is ideal in situations where you need to quickly bring the building into a decent appearance. In a short time, you can update the walls and ceilings of the building, while avoiding complex expensive repairs.

Metal siding. It is a lightweight long panels of various widths: 120, 300 and 550 mm. On each panel there are locks with which they are fastened together.

The most common material is galvanized steel. The surface is coated. One of the coating options is a polymeric material - polyester, plastisol, pural. In this case, the choice of color is limited to only six to eight shades. Another type is coloring by applying a special powder. With this method, the color scheme is much more diverse.

Metal siding has advantages over vinyl:

- increased strength characteristics;

- durability;

- resistance to sudden changes in temperature;

- color fastness;

- incombustibility.

In addition, metal siding has hidden fasteners, which greatly improves the appearance of the structure. This is especially important when it comes to facade cladding.

Ceramic siding

Ceramic siding is a fairly new invention for cladding and decoration of the front side of the building. This is the best finishing material in the middle price category. Developments related to ceramic siding belong to practical Japanese specialists. They try to use everything that nature gives with a benefit and rational approach.

Ceramics for siding is a mixture of clay interspersed with other natural materials. The panels are environmentally friendly, hypoallergenic and fireproof. The quality of the ceramic cladding can safely be compared with ceramic tiles of increased strength.

Cement siding

The composition of cement siding includes cellulose fiber and, in fact, cement. At the final stage of manufacturing such panels, a wood-based texture is applied to the surface using a special method.

Among the many advantages of cement siding, the following can be distinguished:

- good resistance to temperature extremes, precipitation, wind, ultraviolet rays, mold, fungus;

- cement siding is not exposed to insects;

- allows you to quickly update an existing building, give it a fresh look, decorate the facade, align the walls;

- the possibility of use in buildings with increased fire safety requirements due to high fire resistance qualities;

- long term of operation;

- good color fastness;

- ease of installation and ease of maintenance.

Compared with other species, the following disadvantages can be called:

- heavy weight, for which the crate should be more durable;

- high price;

- inconvenience and complexity during slicing: it is necessary to use protective equipment (masks or respirators) to avoid contact with the face and lungs of silicon dust.

Wood siding

In another way, wooden siding is called glued lining. The panels are made of wood fibers, pressed at high pressure and high temperature. To better connect the fibers to each other, special resins are added.

For reliable protection against external influences, wooden siding has to be covered with several layers of varnish or paint. Recently, wooden siding is used less and less. And with the advent of new materials, it completely fades into the background.

This is due to the following disadvantages of this material:

- high price;

- short term of operation;

- tendency to ignite;

- high moisture absorption;

- the need for tinting and impregnation over the entire service life, so as to last longer without major repairs.