Which siding is best for house sheathing - material comparison

Siding is a wall cladding for a curtain wall. These are flat profiled long lengths that are sewn onto the frame subsystem, mounted on the base wall. When deciding on the installation of a curtain wall, it is necessary to decide which siding is best for covering a house, since there are several types of them, and there are some features of their application.

Content:

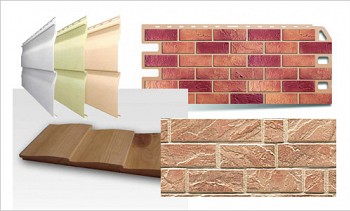

Popular varieties of siding

Depending on the materials used, siding can be:

- vinyl

- acrylic

- steel

- fiber cement.

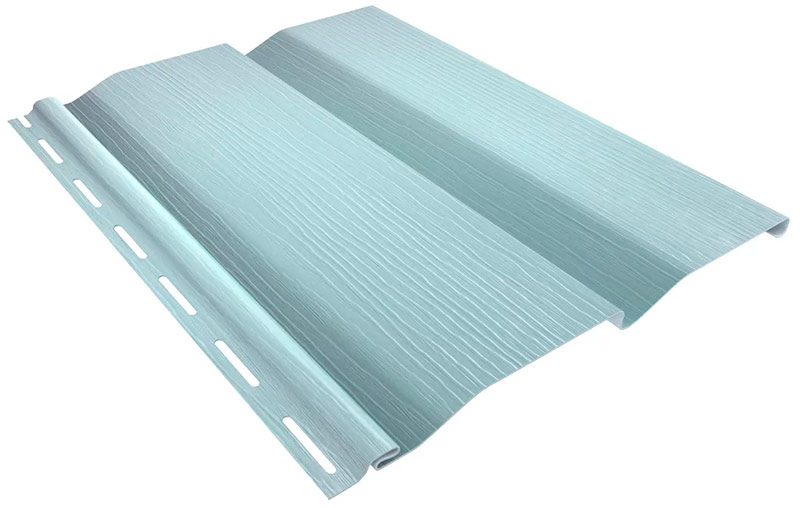

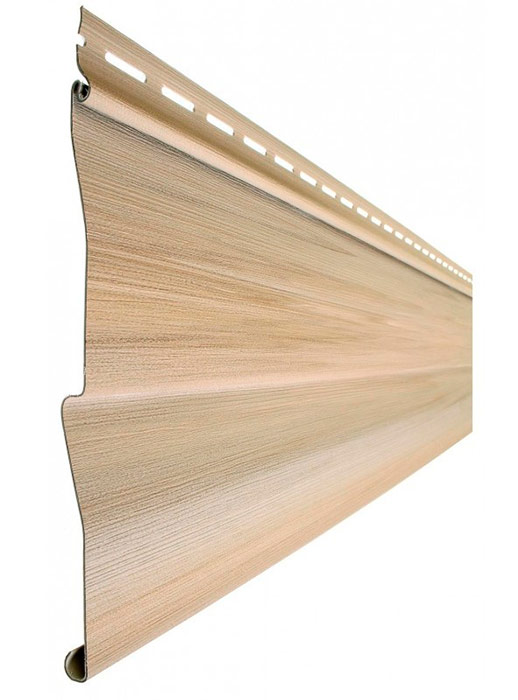

Vinyl siding

Vinyl siding is the most popular. It is made of polyvinyl chloride - plastic, characterized by chemical inertness and a wide temperature range of operation. The longitudinal profile gives the panels the required bending stiffness with a small sheet thickness.

Acrylic siding

Acrylic is called a siding with a vinyl base and an acrylic face layer. Vinyl provides the necessary mechanical qualities of the panels, and acrylic due to its higher resistance to sunlight makes it possible to obtain a lining with a bright, resistant color.

Metal siding

Metal siding is cold rolled from thin steel sheet. The formation of the profile gives the panels a sufficiently high strength with a small thickness of the starting material and low weight. Metal siding is protected from corrosion by galvanizing and polymer paint.

Protection consists of several layers:

- zinc or aluminozinc coating, providing electrochemical corrosion protection;

- passivation - chemical treatment of zinc, forming on its surface a thin protective film of stable oxides;

- primer - a layer providing adhesion of the paint to the metal;

- powder paint, from which, when exposed to an oven, a durable protective and decorative film is obtained that can withstand metal deformation, exposure to moisture and sunlight.

Fiber cement siding

Fiber cement siding is made from a mixture of cement with mineral fillers and fiber. Fiber is a thin glass, polymer or cellulose fiber that creates dispersed reinforcement in the entire volume of panels and gives them strength and resistance to cracking.

When deciding which siding to choose for a particular case, you need to determine the conditions for its use and select the material with the most suitable characteristics. Next, we compare the given types of siding by the main parameters.

Which siding is stronger

The hinged facade usually does not have high strength requirements, so the material for cladding is usually designed for wind loads and is quite easily damaged by concentrated mechanical stresses. The highest strength is fiber cement siding. Its strips have a thickness of 10-12 mm and can easily withstand most of the stresses that may arise during operation - a hand push, a ball hit, etc. This cladding is sometimes used in the basement of the building, where such loads are most likely.

Metal siding is less durable due to the small wall thickness. In an effort to reduce the material consumption of the casing and reduce its weight, manufacturers of metal cladding use a thin sheet, and bending stiffness is achieved by forming a profile that increases the structural thickness of the planks.Metal siding can withstand quite large loads, but when a certain limit is reached, which depends on the thickness of the metal, the height of the profile and the pitch of the subsystem, dents appear on it, which can only be removed by replacing the panels.

Plastic siding is relatively easy to deform, but just as easily restores its shape if the elastic limit is not exceeded. Due to this quality, it successfully serves as a facade cladding.

At low temperatures, plastic becomes more brittle and can burst from shock passing without a trace in warm time. Lower limit of safe temperature, -50aboutC, virtually unattainable for most regions. In the summer heat, the material approaches a state of fluidity, but up to +50aboutWith the elasticity of vinyl remains high enough. Acrylic siding withstands more heat - up to +80aboutFROM.

Damage to vinyl siding in a large hail.

If you create a list of siding in order of increasing strength, it will look like this:

- vinyl

- acrylic,

- steel,

- fiber cement.

Durability - the sister of strength

The service life of facade cladding is related to its strength, but not always “durable” means “durable”. Various factors influence this parameter, and it is not always possible to unambiguously indicate the most durable material. We will deal with this issue.

Stone durability

Among the types of facade cladding under consideration, the highest hopes regarding longevity are provided by fiber cement siding. This material is theoretically eternal, since in fact it is a stone reinforced by fibration. However, humidity and low temperature are adjusted for the life of this cladding.

If the panels are not protected against moisture and are operated in cold climates, they are susceptible to frost damage. High-quality cement cladding should have frost resistance at the level of 100-150 cycles, which means 20-50 years of trouble-free operation at normal humidity. This material is completely indifferent to solar heating.

If the operating conditions of the facade do not contribute to the appearance of moss, mold, microscopic algae on its surface, then its appearance remains unchanged throughout its service life. Mineral dyes are used for coloring, which do not lose color over time.

Corrosion-free metal

Corrosion of iron casts doubt on the durability of the facade cladding of steel sheet. But here modern protective coatings come to the rescue. The zinc layer forms a galvanic pair with iron, which prevents its oxidation, and the polymer paint serves as a reliable protective layer, resistant to mechanical damage and cracking. The service life of metal cladding is at least 10 years. Today, manufacturers guarantee up to 20-25 years of operation without significant manifestations of rust.

Metal siding does not react to low or high temperatures. It does not experience frost damage, does not become brittle in the cold, does not lose strength when heated. The only thing to consider during installation is the thermal elongation of the lamellas.

The entire service life of the appearance of the siding is practically unchanged, with the exception of the burnout of some helmets. Over time, the color of the facade may lose its initial saturation.

"Eternal" plastic

Plastic siding, despite the fragility of PVC, is the most durable under the conditions of its use. The claimed service life is 50 years.

It is achieved due to several factors:

- plastic does not absorb water at all, which means it is not subject to frost damage;

- fungi, moss and algae do not take root on polymers; insects are not interested in them;

- chemical inertness makes the casing insensitive to weathering;

- UV resistance of the plastic is ensured by the addition of stabilizers.

Despite the use of photostabilizers, the color of PVC changes over time. Coloring loses its intensity, and white plastic may acquire a yellowish tint.Therefore, vinyl siding is painted in bright colors with low saturation.

In order to obtain more saturated colors, an acrylic face layer is used. Acrylic is more resistant to heat and ultraviolet. It is much less prone to fading. Even based on these parameters, you can understand which siding is better - vinyl or acrylic. Acrylic siding expands the possibilities of design and allows you to preserve the bright colors of the house longer.

The temperature range of operation of plastic sheathing is limited, but wide enough. As a rule, heating by sunlight does not lead to a decrease in strength. In severe frost, siding can become brittle and burst from a not too strong blow. Another feature of PVC is its high coefficient of thermal expansion. This feature must be taken into account when installing the facade.

Fire resistance siding

The main and perhaps the only danger associated with the use of hinged facade systems is the danger of fire. This problem is especially important for facades with a ventilated interlayer. The rod arising in the ventilation gap inflates the fire and quickly spreads it all over the wall.

Fiber cement siding has the highest fire resistance. It not only does not burn, but is also able to survive the local effects of fire without special consequences.

Metal siding is also completely non-combustible. But when exposed to fire, it loses its appearance, loses its corrosion protection and becomes unsuitable for further operation.

PVC can be made to burn. But this plastic does not spread the flame and burns only with external exposure, attenuating when the heating ceases. The front acrylic layer does not change the overall picture.

Vinyl siding after a fire.

Environmental friendliness

In terms of environmental friendliness, any of the options considered is not satisfactory. Some advantage can be attributed to fiber cement cladding, since it contains only natural components. However, polymer modifiers may also be added to the cement mixture.

Operation and maintenance

In terms of ease of use and surface care, plastic is beyond competition. Its smooth surface is easily cleaned from dust and dirt. Even strong scratches are invisible on it, since surface damage does not lead to a color change.

Metal siding is also easy to care for. But any scratches need to be painted over to restore the appearance and corrosion protection of the facade.

Fiber cement siding, like plastic, is insensitive to minor damage. The disadvantage may be some porosity of the material. It can make surface cleaning difficult, and in some cases a green coating may appear on the skin, which is very difficult to remove.

Facade Design Issues

Choosing the option of the curtain wall, you need to consider the convenience and ease of use, as well as the cost of acquiring the material, its delivery, the complexity of installation.

Convenience of installation is dominated by metal and plastic siding. Their lamellas are easy to manipulate, hold in place until locked. Metal siding is slightly heavier than vinyl, but in most cases this difference can be neglected.

When deciding which siding is better - vinyl or metal, it is worth considering that vinyl is easier to cut and bend. During installation, various techniques are often used, associated with bending the notched parts, which in the case of plastic is much easier to do. Vinyl parts can be significantly bent without irreversible deformation, which also simplifies the work.

Due to the ease of installation, vinyl and metal siding as a result are inexpensive. Plastic is especially economical since the material itself is cheaper.

Fiber cement siding is expensive to purchase and more difficult to install. It has more weight, which makes higher demands on the subsystem. This also increases the total cost of the installation of the curtain wall.

The best material, as always, is the one that best fits the task and meets the conditions of use.

The final comparison of siding of various types

|  |  |  | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vinyl | Acrylic | Metal | Fiber cement | |||||||

| Ruggedness and reliability | Average | Average | High | Very high | ||||||

| Durability | 56 years | 50 years | 20 - 25 years old | 20 - 50 years old | ||||||

| Invariance of appearance | Low stability | High stability | Medium stability | High stability | ||||||

| Flammability | Melts and burns when exposed to external flame | Melts and burns when exposed to external flame | Does not burn | Does not burn | ||||||

| Relation to temperature differences | Subject to thermal expansion, at low temperatures it becomes tiny | Subject to thermal expansion, at low temperatures it becomes tiny | Subject to thermal expansion | Not subject to temperature fluctuations | ||||||

| The cost of material and arrangement of the facade | Low | Average | Average | High | ||||||

| Environmental friendliness | High | High | High | Very high | ||||||

| Facade weight | Easy | Easy | Average | Tall | ||||||

| Mounting | Plain | Plain | More complicated | More complicated | ||||||

| Care | Easy | Easy | Easy | May be difficult | ||||||