Technical characteristics and properties of aluminum heating radiators

Many of those who have their own home somewhere outside the city or within it use aluminum batteries for space heating. After all, aluminum radiators technical specifications are quite suitable for this. Next, we’ll put their characteristics on the shelves and consider why they are so good specifically for mansions and cottages.

Content:

- What are the types of aluminum radiators and how are they made

- What are the technical specifications of aluminum radiators

- Characteristics of popular manufacturers and models of aluminum radiators

- Table: Specifications of popular aluminum radiator models

- Advantages and disadvantages of aluminum radiators

- Video: Installing aluminum radiators

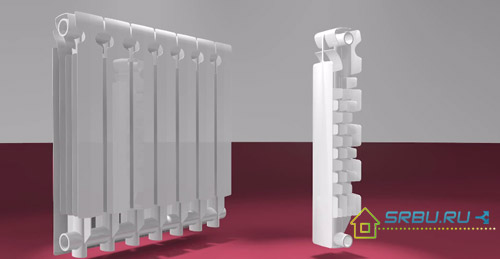

What are the types of aluminum radiators and how are they made

In the process of manufacturing these radiators, special silicon additives are added to the aluminum melt to achieve strength. Either separate sections or collectors are produced from the resulting mass. Consider the two main methods of manufacturing these heating devices - this is the casting method and the extrusion method.

Casting method

This method assumes that all sections are done separately. They are poured from silumin (the so-called aluminum with the addition of silicon). The content of silicon additives does not exceed 12% - this is enough for strength. Casting is at high pressure. As a result, sections of various shapes can be obtained. They are able to withstand from 6 to 16 atmospheres. To water freely passed through radiators, make extended water channels. And to make the battery strong, its walls are made thick enough.

Separate sections fasten in one radiator.

Extrusion method

Extrusion is extrusion (in a more understandable language). This method involves the manufacture of individual parts of the radiator. Then they are held together. However, only vertical parts are made by extrusion. Making them from aluminum with certain additives. But the collector is poured from a silumin alloy. Although sometimes it is also done by extrusion, immediately a certain width. Then all the parts are pressed, tightly connecting them. This method is cheap, but a battery made with it cannot be improved during use.

It is impossible to remove a section from such a radiator, as well as put additional ones.

Anodized batteries

This is a separate type of instrument made of purified aluminum of very high quality. They undergo anodic oxidation, which changes the structure of the metal, thanks to which it is almost not affected by corrosion. Separate parts are connected not with nipples, as usual, but with couplings mounted on the outside. This gives smoothness to the inside of the anodized radiators. Therefore, their heat transfer is better than that of ordinary aluminum batteries. The working pressure that anodized devices withstand is 50, or even 70 atmospheres, but they are also quite expensive.

What are the technical specifications of aluminum radiators

Distance between axles

Standard values are 500, 200 and 350 millimeters. They are abundant in the construction market. But there are also radiators with a distance between the axles that is different from the standard. It can vary from 200 to 800 millimeters.

Most often, you can find radiators with a distance between the middle of the lower and upper manifold of 500 millimeters. Some 580 millimeters make them tall.

When buying a radiator, first measure the distance under the windowsill - after all, it is there to put it. It is impossible for the radiator to fit end-to-end - warm air will not be able to circulate freely, so convection heating will be difficult.

Between the floor and the battery leave a gap of 10 centimeters (you can, however, more).The same gap should remain from above - to the back of the windowsill. Well, you need to retreat from the centimeter wall by 3 - then everything will be all right.

See that in width, all sections fit in the space provided for the radiator. And if it turned out that the heater doesn’t fit well in height or width, it’s better to take another one, a little smaller. So, for example, with a distance between the axes of 350 millimeters, the height of the battery will be 100 millimeters more. Be sure to consider this nuance when buying.

Pressure and its two types

For radiators, it is customary to indicate in the passport both the working pressure and the pressure test. Moreover, the latter is significantly higher. And sometimes they also indicate the maximum pressure. The amateur cannot immediately figure out what all these characteristics mean.

But everything is simple: the pressure called the worker is the one at which the battery will be used. For aluminum radiators, its standard values are 10 - 15 atmospheres.

In central heating networks, pressure is usually 10-15 atmospheres, while in heating mains 30 atmospheres is not uncommon. Therefore, it is not safe to use aluminum radiators for an apartment with central heating.

But for your own home, the pressure in a domestic-made boiler is usually only 1.4 atmospheres. Sometimes it is indicated in bars - these two units are similar. For boilers from Germany, the working pressure is higher - about 10 bar. Here you can already use aluminum radiators.

Pressure, called crimping, is often even more important to know than working pressure. After the summer (when the water from the batteries was drained), before starting the heating system, you must first check whether this system is tight. To do this, it is pressed, that is, they are tested at elevated pressure, which is higher than the working pressure, one and a half times, or even more. So the standard pressure of pressure testing reaches 20, 25 or 30 atmospheres. This procedure is typical for central heating networks.

Significant differences in working pressure for private houses and high-rise buildings are explained simply. After all, pressure shows to what level water can reach up. So, one atmosphere (otherwise, one bar) pushes water up 10 meters. This is enough for a three-story house, but not enough for a four-story building. But public utilities do not always supply water under the declared pressure. Sometimes it goes off scale so that even the most durable and expensive batteries burst.

So it is best to buy heating appliances with a margin of pressure. They will not only be able to withstand the pressure of hot water in the heating system, but will also live long. Such a reserve of pressure will also serve as a guarantee of additional durability and long serviceability of your batteries.

Different manufacturers indicate different pressure units in the passport. As mentioned earlier, one bar corresponds to one atmosphere. And if the pressure is indicated in megapascals (MPa), then to translate it into atmospheres, we multiply this value by 10. Thus, 1.2 megapascals corresponds to 12 atmospheres.

What you need to know about thermal parameters

One second of the heat given off by aluminum batteries is heat rays. The remaining heat is convection, which is formed when the air layers move from the bottom of the radiator up. Due to the ribbed surface of the inner side of the sections, the heat transfer is very significant.

The room is heated with an aluminum radiator in two ways - by direct heat radiation and convection.

The heat transfer coefficient is indicated in watts. It is given, as a rule, for one section. Take, for example, a battery with an axle spacing of 500 millimeters. The heat transfer of its section will be from 100 to 150 watts. Multiply by the number of these sections - this is the general value, according to which the main thermal calculations are carried out.

You need to know that high heat transfer corresponds to a lower inertia of radiators. This helps to save money, therefore, in terms of efficiency, aluminum batteries are the leaders. They left behind both classic cast iron and newfangled bimetal. After all, their heat transfer is higher, and their inertia is less.It is necessary to heat the water to a lower temperature, respectively, and the boiler wears out more slowly.

A bit about design

Aluminum alloy radiators, although not dazzling with luxury and high cost, often embody interesting design solutions. Therefore, they fit perfectly into the various interiors of modern apartments and houses. So people choose not fashionable expensive new items, but aluminum radiators that have stood the test of time. They will not let you down in difficult times, and they will decorate the house.

Service life of aluminum radiators

Typically, manufacturers guarantee that the aluminum battery will last 10 to 20 years. Famous brands sometimes become generous even for a quarter of a century. When the declared warranty period has passed, you should not immediately carry the batteries in the trash. Just periodically inspect them, carefully looking at the slightest flaws.

The main technical characteristics of aluminum radiators are as follows:

- The distance between the upper and lower collector (center) - from 200 to 500 mm;

- pressure (working) - from 6 to 16 atm;

- power (thermal) - from 82 to 212 W;

- the weight of one section is from 1 to 1.47 kg;

- the capacity of one section is from 250 to 460 ml;

- limit temperature of the heat carrier - 110 degrees;

- Warranty - from 10 to 15 years.

Characteristics of popular manufacturers and models of aluminum radiators

Manufacturer FARAL originally from Italy

He supplies two types of batteries to us: FARAL Green HP and FARAL Trio HP. They have a distance between the axes of 50 and 30 centimeters, and a depth of 9 and 8.5 centimeters. The number of sections assembled is from three to sixteen. These sections are attached to each other with steel nipples. For sealing put gaskets.

Before shipment to the consumer, the plant tests the batteries by applying 24 atmospheres pressure (gauge) to them. Such a check will allow the radiators to withstand the working pressure of 16 atmospheres.

KalidoR radiators are also Italian - Radiatori 2000 S.p.A.

The production is located in the city of Bergamo and uses the most modern technologies in the production of batteries. Therefore, the characteristics of the aluminum radiators made by this company are simply excellent. For example, good heat transfer and low susceptibility to corrosion can be mentioned. Their color is strong, which is done using the anaphoresis method, which ends with epoxy-polyester spraying. The plant conducts tests at a pressure of 24 atmospheres, which corresponds to a working pressure of 16 atmospheres.

Radiators are strong, last a very long time and have a beautiful design.

Third "Italians" - ROVALL batteries from the Sira Group

His popular models are: TANGO, OPERA, ALUX, JAZZ, BLUES, SWING. For the manufacture of radiators, extruded aluminum pipes are taken. Batteries have a wide range of colors, and their surface is treated in a special way. For Russia, tests are carried out at a pressure of 30 atmospheres (respectively, the working pressure is 20 atmospheres).

Using special technology, the company makes it possible to vary the height of the batteries in the range from 20 to 250 centimeters. Therefore, they can be installed in any niche.

Popular Manufacturer - Fondital

And he is also from Italy. But its Calidor Super battery is specially designed for the CIS countries and Russia, therefore, it perfectly suits the natural conditions of these countries. In its manufacture, Russian standards (GOSTR RU.9001.5.1.9009) and European standards (EN 442) are observed. These aluminum alloy radiators are poured under pressure. The maximum resistance to pressure from the inside is 50 atmospheres.

The increased diameter of the water channels prevents the radiators from clogging with not very clean water, and the thickened walls give the necessary strength.

Table: Specifications of popular aluminum radiator models

* All values in the table are for 1 section and are taken from the official websites of manufacturers.

** Indicated thermal power at 70 0FROM.

| Brand, country | Model | Distance between axles, mm | Dimensions H / W / D (sections), mm | Maksim. working pressure, bar. | Thermal Power, W | The volume of water in the section, l | Weight, kg |

|---|---|---|---|---|---|---|---|

Faral Italy |

GREEN HP 350 GREEN HP 500 TRIO HP 350 TRIO HP 500 |

350 500 350 500 |

430/80/80 580/80/80 430/80/95 580/80/95 |

16 | 136 180 151 212 |

0,26 0,33 0,4 0,5 |

1,12 1,48 1,23 1,58 |

| Radiatori 2000 S.p.A. Italy |

350R 500R |

350 500 |

430/80/95 577/80/95 |

16 | 144 199 |

0,43 0,58 |

1,4 1,6 |

ROVALL Italy |

ALUX 200 ALUX 350 ALUX 500 |

200 350 500 |

245/80/100 395/80/100 545/80/100 |

20 | 92 155 179 |

0,11 0,11 0,23 |

0,83 0,82 1,31 |

Fondital Italy |

Calidor Super 350/100 Calidor Super 500/100 |

350 500 |

407/80/97 557/80/97 |

16 | 144 193 |

0,24 0,30 |

1,3 1,32 |

| Rifar Russia |

Alum 350 Alum 500 |

350 500 |

415/80/90 565/80/90 |

20 | 139 183 |

0,19 0,27 |

1,2 1,45 |

Advantages and disadvantages of aluminum radiators

Positive traits

- Aluminum batteries are very economical.

- Their low weight does not cause inconvenience during installation and dismantling.

- There is a regulator to control the temperature.

- The installation of such heating devices is not difficult.

- The heat transfer coefficient is the highest.

- These radiators look very presentable and original, so they can be used in ordinary apartments and in luxury rooms.

Negative points

- At intersection joints, water leakage is possible.

- Heat is distributed extremely unevenly, mainly focusing on the ribbed surface of the sections.

- Convection heat transfer is very small.

- They serve not very long - until the age of fifteen. However, some manufacturers fixed this - they increased the warranty to twenty and twenty-five years.

- The formation of gases is possible.

- Aluminum is distinguished by high chemical activity, therefore corrosion is its strong enemy. To protect the batteries from this enemy, manufacturers carry out a special anti-corrosion treatment of the batteries. Or cover them with a layer of oxide film.

The chemical activity of aluminum is perhaps the main disadvantage of batteries made of this material. Therefore, when there is chemical impurity in the hot water circulating in the central heating system, an accelerated destruction of the radiator walls occurs as a result of a chemical reaction. And aluminum radiators are very sensitive to pressure instability in the heating system.

Because of these shortcomings, such radiators are best used only in autonomous heating systems. There you will be sure that there will be no “chemistry” in the neutral hot water flowing through the radiators, the pH of the coolant will be neutral, and the pressure in the system will not jump to unlimited values. But in an apartment it is dangerous to install aluminum radiators - even there is a ban on this from the relevant authorities.

Video: Installing aluminum radiators