The device of the roof truss system

For a rebuilt house to serve for many years, being strong and reliable, it needs not only a good foundation. An equally significant element is the roof rafter system, which takes on all the vicissitudes of the weather. And she must withstand the load in the form of gusts of wind, heavy snowfalls and heavy rains. Let's talk about how it works and how to build this system.

Content:

Requirements for the rafter system

Rigidity

First of all, every detail of the system, as well as the joints, must be rigid, without deforming either under shear force or under pressure. The basis of the whole structure is a triangle. It is this form of frames (trusses) that are fixed parallel to each other. Their rigid fixation provides the roof with the necessary stability. But if the farm turned out to be mobile, not far from trouble. Such an inferior roof can itself collapse, and the walls collapse.

Light weight

The roof should not be heavy, so the rafter system is usually made of wood. If the weight of the roof is solid, then the supporting base is made of metal. Or take a coniferous tree, not lower than the first grade, with a moisture content below 18 percent. The use of antiseptic treatment and the use of flame retardants to protect against fire are two prerequisites. Then the fastening nodes of the roof truss system will be strong and strong.

High quality material

The tree for the rafters should be as follows:

- Wood is taken 1 - 3 grades. Cracks and knots should be kept to a minimum. There can be 3 knots per meter no more than 3 cm high. Cracks are not permissible over the entire depth, up to half the length of the board.

- Bearing elements are made of wooden parts from a thickness of 5 cm, an area of 40 cm2.

- Coniferous boards can be up to 6.5 m long, and deciduous - up to 4.5 m.

- Girders, pillows and Mauerlat are made from hardwood. They are treated with an antiseptic.

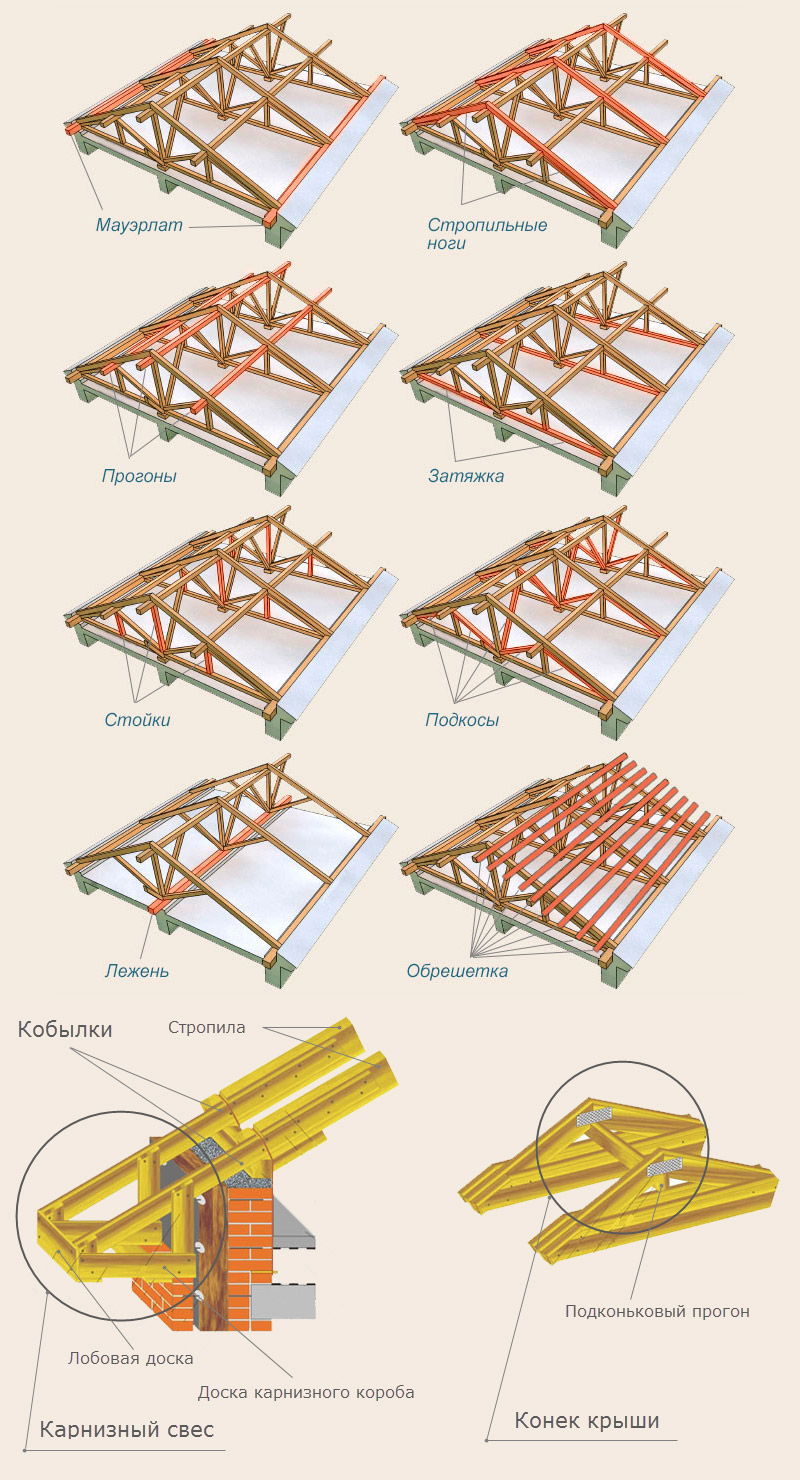

The main parts of the design of the rafter system

Thinking over the device of the roof truss system, you need to know what parts this system consists of.

#1. Mauerlat - this is the foundation of the whole system. It helps to evenly distribute the load on the walls.

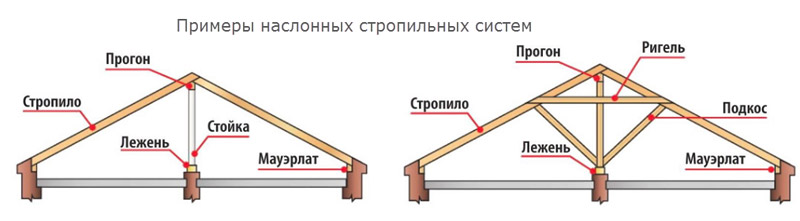

#2. Rafter leg determines the angle of inclination of the slope, as well as the general view of the roof, rigidly fixing individual elements.

#3. Run - fastens the rafters legs. The ridge run is at the top, the side runs are on the side.

#4. Puff - does not allow the rafter legs to disperse, connecting them below.

#5. Racks and struts - give rafters legs additional stability. They rest against the lying (which lies below parallel to the ridge).

#6. Crate - Stuffed perpendicular to the rafter legs and is a cut bars or boards. It is designed to transfer all the load from the roofing material to the rafter legs.

#7. Skate roof - This is the junction of the two slopes of the roof. A solid lath is crammed along the ridge to reinforce this part of the roof.

#8. Mares - used to create an overhang in case the length of the rafter legs is not sufficient.

#9. Eaves - This is an element designed to protect against excessive rainfall on the walls.

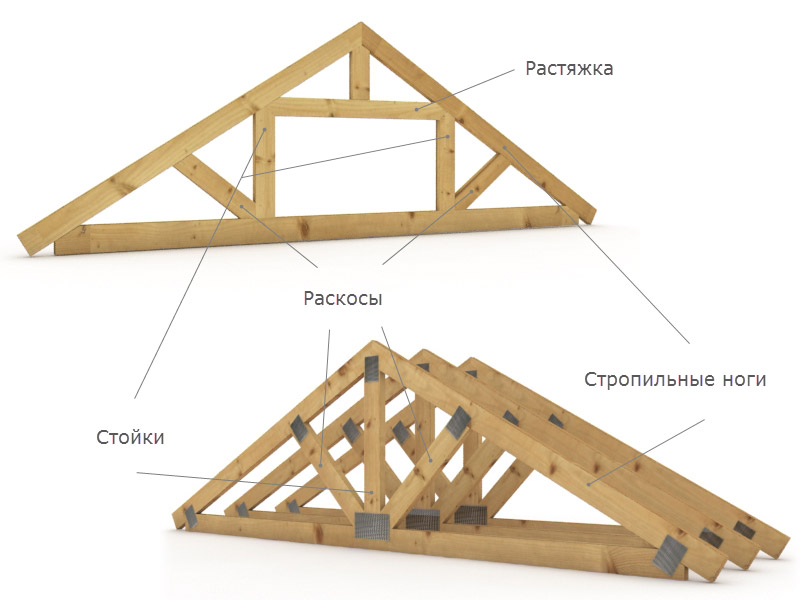

Now consider a complex site such as a truss truss. It has a flat shape, and are included in it, except for rafters, extensions, racks and braces. They are positioned so that the load on the walls inside the house does not occur. Only its external walls are supports, and the load goes vertically.The distance between farms is determined by calculations. If the span is large, then the farm consists of several parts. In the attic, the lower girdle of the farm serves as a ceiling.

The above are examples of wooden trusses, in addition, in some cases, trusses made of concrete and metal are used.

Forms of roofs and roof systems

Shed roof.

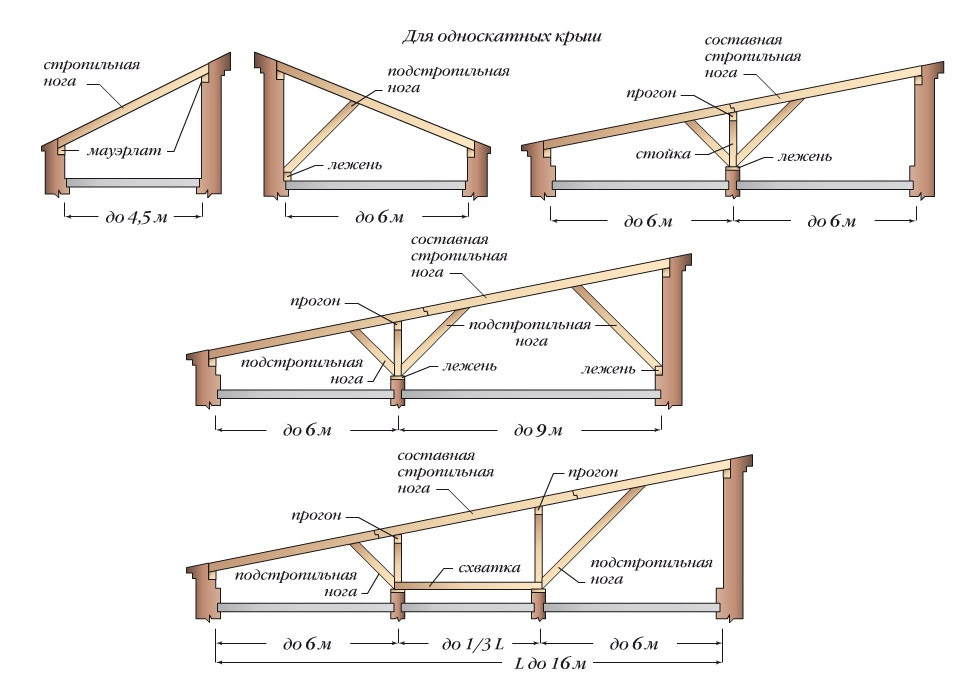

The simplest device of the rafter system has a roof with one slope, which is inclined at an angle of 14 to 26 °. If the house is small, and its span does not exceed 5 m, then a rafter type system is required. It relies on external walls, as well as on the wall inside the building (if any). When the span is more than 5 m, you need to use truss trusses.

The device of the rafters of a shed roof.

Gable roof

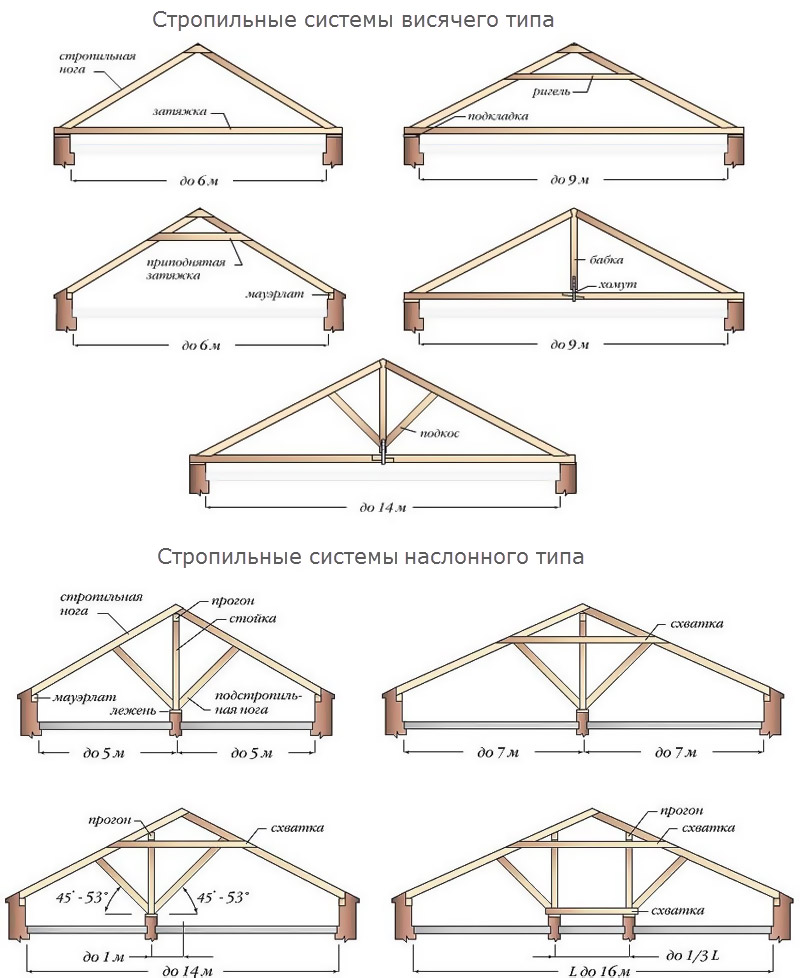

The roof with two slopes is also uncomplicated, under it is an attic or attic. Its bias is from 14 to 60 °. If the outer walls are less than 6 meters apart, they make a hanging rafter system. The roof rafters must be used when the span is large and there are internal supports.

The device of hanging and layered rafters of a gable roof.

- More about it in the material: Rafter system of a gable roof and its device

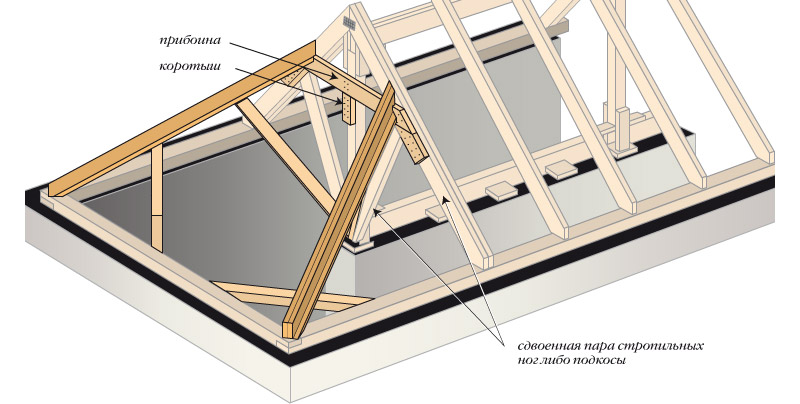

Four-pitched roof

A roof with four slopes is called hip or half-hip. Its slope is from 20 to 60 °, and the span can be up to 12 m. In this case, there must be internal supports. There are no front walls in this case, which saves materials. However, installing such a roof is more complicated than a gable roof. For such a roof structure, rafter systems are made either of a layered type, or with the use of truss trusses.

Features of the construction of a gable roof.

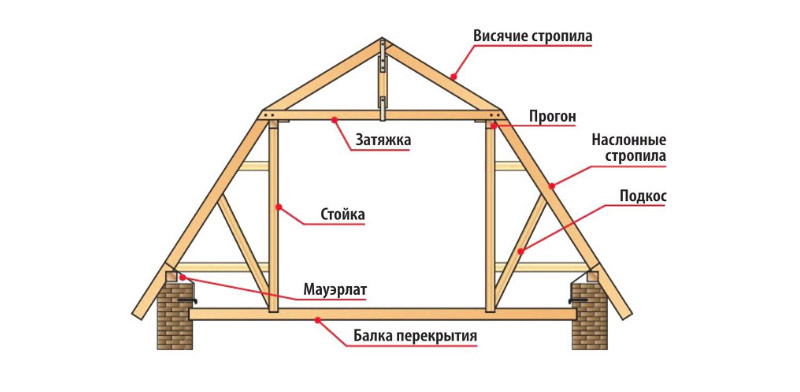

Broken roof

The roof is broken or mansard, at the bottom it can have a slope of up to 60 °. But above it is usually more gentle. Due to this, the attic area is increasing. Such a roof is good for houses where the width does not reach 10 m. As in previous cases, you can use a layered rafter system. However, farms are preferred.

Broken roof device.

- The most common, but not all forms of roofs are listed above, for more details see the material:Types of roofs of private houses by design and geometric shapes

Types of rafter systems - how do they differ among themselves

This or that type of rafter system is chosen not spontaneously, but depending on the design of the house under construction and its size. Further about each type of rafter systems.

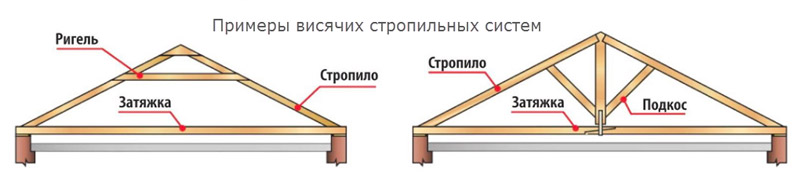

System with hanging rafters

They are good for roofs with two slopes, where the span is not more than 6 meters, and there are no walls inside. At the bottom, the rafters are supported by a Mauerlat, and at the top, they are supported by each other. There is also a puff that reduces the strut rafters on the walls of the house. Beam puffs are located at the very bottom of the rafter legs - they simultaneously serve as floor beams. By the way, the overlapping of the upper floor, made of reinforced concrete, can also play the role of a puff. If the puff is made higher, it is already called a crossbar. If the span between the outer walls is more than 6 m, it is necessary to use support struts and braces to maintain the rafter legs. In this case, the length of the lower part of the rafters, i.e. the part after the support, is long, should be no more than 4.5 m.

We list a few important facts about their design:

- It is not worthwhile to lean the roof overhang on the bottom of the rafter legs extended outside the wall. It is much better to support the filly for supporting such roof truss systems (at the same time, the width of the overhang is up to a meter). And then the leg will rest on the Mauerlat with the entire plane. The cross-section of the filly is usually smaller than the cross-section of the rafter legs.

- On a slope you need to nail a wind board, from the ridge to the Mauerlat. The slope is done from the attic. This is necessary so that the roof becomes rigid, does not stagger and is not destroyed by the wind.

- If the humidity of the wooden truss material is more than 18%, get ready for the fact that the rafter system after drying the wood can become unstable. Therefore, connect such a tree not with nails, but with bolts - you can tighten them if something happens.Better yet, use screws or rough nails.

Rafter systems

They are suitable for roofs, where the span is from 10 to 16 m. The slope can be any, and inside the building there should be load-bearing walls or columns. At the top of the rafters rely on the ridge run below - Mauerlat. The ridge run is supported either by an internal wall (lying) or by uprights. Since the loads are only vertical, there is no need to tighten.

When the span is large (up to 16 m), you can replace the run of the ridge with two side ones that will rest on the racks. So that the rafter legs do not bend, you need braces and crossbars. If an attic is made, a wall with a height of 1 to 1.5 m can be used as a support for the built-up nylon. Well, or use a broken mansard roof (with broken slopes).

What you need to pay special attention to:

- Each of the elements of this system should not have a thickness of less than 5 cm.

- A smooth, ragged surface of all the nodes of the rafter system is a necessary condition. So they will not rot and will not be so susceptible to fungus.

- Adding additional nodes "from the lamp" in the calculated rafter system is prohibited. Otherwise, the load may not be where it is needed.

- Mauerlat (his sole) must lie strictly horizontally relative to the walls. Requires horizontal position and the docking surface of the Mauerlat with the rafter leg. Otherwise, the support may tip over.

- Racks and struts have the most symmetrical.

- So that the rafters are not wet and do not rot, they make good ventilation. For this, gaps are provided in the roof of the attic, and air in the roof of the attic.

- Where the rafters are joined with masonry, waterproofing is needed. Otherwise, condensation will ruin the tree.

- Having no support or strut, the rafters foot is made no more than 4.5 m long.

Connecting elements

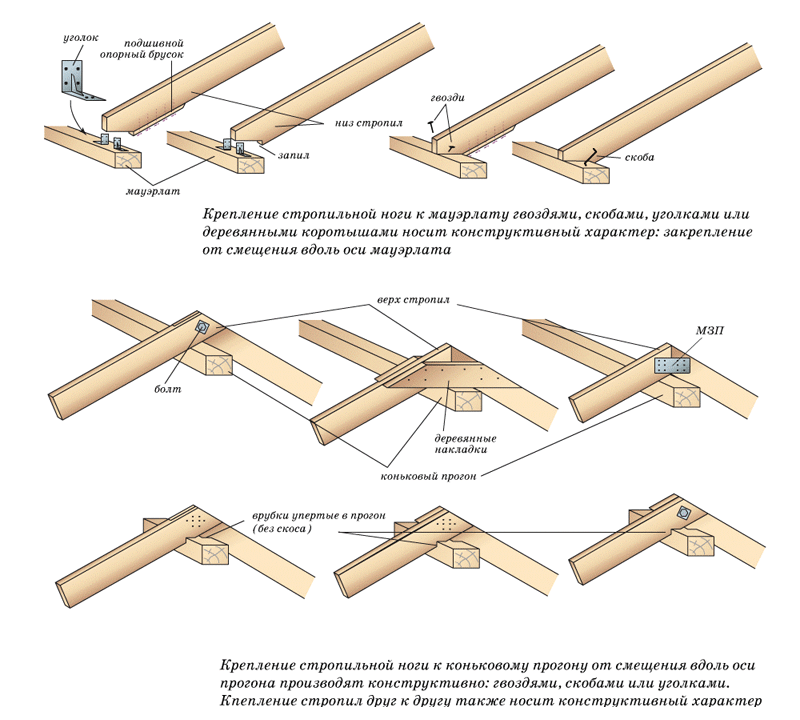

To make the roof reliable, the nodes of the rafter system must be connected correctly. It is necessary to take into account the direction and strength of the loads (both static and dynamic). It is also important to provide for possible cracking of the tree from drying out, making sure that the nodes of the rafter system do not stop working properly.

Previously, all the details of the rafter system were fastened together by notches. It is reliable, but not too economical. Indeed, for this it is necessary that wooden structures have large sections, which would make it possible to make cuttings safely weakening wooden elements.

Therefore, at the present time, the nodes of the rafters are fastened not with cuts, but with pins and bolts.

Methods of fastening the rafter legs.

The use of perforated steel plates having a coating against corrosion is popular. Fix the pads with nails or plates with teeth recessed into the tree. Such fasteners for the rafter system are convenient in that:

- Pads reduce wood consumption by one fifth, since elements of a smaller cross section are required than with a cutting;

- they can be mounted by a master with not very much experience;

- they are fixed very quickly.

Perforated plates used for fixing rafters.

Lastly, you can watch a useful video that talks about all the most important points in the design of the roof truss system.

Material prepared by the authors of the project Electricianexp.com