Ocified log - advantages and disadvantages of the material

Round log - a modern material for the construction of houses in the ancient way. What qualities a round log has, its pros and cons, as well as the advantages and disadvantages of a house from it - the topic of this article.

Content:

Features of the manufacture and construction of logs

The rounded log is made of straight wood trunks. Their processing on a cylindering machine looks like a turning groove in a cylindrical part. The workpiece is fixed from two ends and is rotated around a longitudinal axis. The cutting tool moves along the barrel, cutting off the excess, and giving it the shape of a cylinder. In order for the treated log to retain its shape, it is first dried to atmospheric humidity.

A longitudinal lunar groove is made on the log processed in this way, which is necessary for tightly mating the log crowns, and a compensation (unloading) cut. Propyl is a groove 5–7 mm wide and 20–25 mm deep. It slightly reduces the internal stresses in the wood that occur during drying, and reduces cracking. If cracks still appear, then not on the side surfaces of the logs, but go out into the groove, which allows you to maintain a perfect appearance of the walls from the outside and from the inside.

Instead of the lunar groove, grooves of a more complex shape can be cut out, including those with two-sided profiling of the log - from above and from below. But in any case, the visible sides remain intact.

The unloading cut can be done simultaneously with the mounting groove or immediately before sending the parts to the construction site, and in some cases it is not done at all. It depends on the quality of the wood, the diameter and length of the log.

When cylindering the trunks, one of the diameters of the standard size range is attached: from 220 to 320 mm, in increments of 20 mm. After completion of the machining, the wood is impregnated with an antiseptic and fire retardant.

The construction technique of logs differs from the traditional procedure. Modern woodworking equipment with detailed design allows you to pre-cut the logs on the details of the desired length and make in them all the cutouts necessary for the assembly of the log house.

With this approach, finished parts are delivered to the construction site that do not require additional processing and adjustment. The crowns are stacked and fastened like Lego blocks. It remains only to establish the pins and interventional ties. This greatly speeds up the construction and improves its quality. The advantages and disadvantages of a house made of logs are a continuation of the advantages and disadvantages of the source material.

The advantages of a log

Everything is known in comparison, so we will compare the logs with other materials.

High speed and impeccable construction quality

This was described in detail in the previous section. In speed and accuracy of assembly, in the quality of the walls, a rounded log significantly surpasses other materials.

Precise processing of parts on special equipment in the factory slightly increases the cost of the material, but gives significant savings due to the ease of assembly of the log house and the simplicity of ensuring its quality.

At the construction site, no more work is done on cutting logs, cutting locks, fitting, etc. Only laying the finished parts, laying the seal, drilling vertical holes and installing pins. The amount of manual work is minimized. Saving time is saving money on the wages of builders.

Low cost

Despite the fact that the logs are subjected to high-tech processing, the degree of this processing is small, so the cost of building material does not increase much from the cost of the original wood. For example, profiled or glued beams are more expensive. Savings are achieved not only due to the nature of the material, but also due to the high speed of construction and minimal labor.

Heat in the house

Wood has a low thermal conductivity compared to brick and other wall materials. Due to this, a log wall with a thickness of only 200-300 mm has the same resistance to heat transfer as a brick wall with a thickness of half a meter or more.

The average thickness of the log wall is higher than that of the beam, since the beam is obtained by cutting from the logs of croaker. On the other hand, precise machining of parts and their tight mating reliably protect joints from blowing. All this gives warm walls that protect well from the cold.

Light weight and durability

A house made of logs has the basic qualities inherent in any log house. This is a relatively light weight and robust construction, the strength of which is given by the interconnections of all parts. Unlike a brick structure, a log cabin can only be completely destroyed. He to the last resists any destructive loads, while maintaining his integrity.

Savings on finishing work.

Smooth surfaces of the logs, their clear geometric shape make complex finishing work unnecessary both inside and outside. It is enough to cover the walls with a protective varnish. In some cases, additional caulking of cracks is required. From the inside, decorative caulking of twisted cord or sealing of joints with special sealant can be performed.

Out of the whole range of finishing work for log walls, only a few are performed:

- grinding logs (if necessary);

- decorative sealing of joints (if necessary);

- coating with protective and decorative varnish.

Quite a bit of trouble, isn't it?

Savings on the foundation

The low weight of the log house allows you to lighten the foundation, reduce its material consumption and the complexity of its construction. For a log house, a columnar or pile foundation is well suited. The lower crowns do not rest on the foundation along the entire length, but at several points, but due to their rigidity they themselves perform the functions of grillages. As a result, less materials are spent on the foundation, and its construction requires less time and labor.

Environmental friendly material

Wood is a natural material and does not contain toxic substances. However, in production, an oversized log is treated with antiseptics. And although this reduces its environmental friendliness, the still logified log remains the leader in this indicator. The walls of the house made of logs breathe, which creates a favorable macroclimate in the house. The rounded ancient house has good aesthetics, the wood is pleasant to the touch and smell.

Disadvantages of Ocified Logs

The main disadvantages of the rounded log as a building material coincide with the main disadvantages of wood. This is susceptible to decay and combustibility, as well as a tendency to warp and crack. These shortcomings are largely eliminated by special measures - antiseptic treatment, impregnation with flame retardants, the device of the discharge groove, fixing the crowns with pins and screw or spring ties.

Log shrinkage and seasonal variations

After the construction of the house, time is required for the shrinkage of the log house. During this time, the crowns fit more densely in their places, the humidity in them is leveled and comes into equilibrium with the humidity of the air. As a rule, the height of the log is reduced by 3-10%, depending on the initial and final humidity, the accuracy of the preparation of logs and the accuracy of the assembly. Shrinkage, postpones the timing of putting the house into operation.

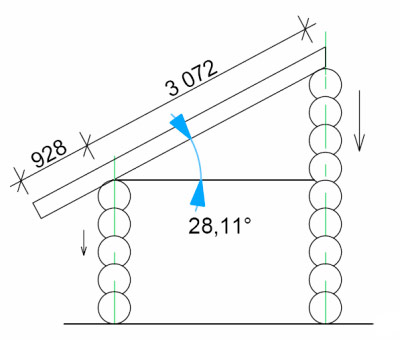

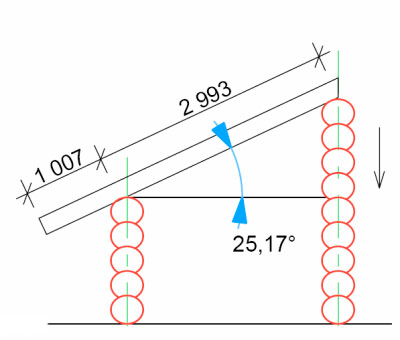

Rafters and walls when installing a log house.

Rafters and walls in a year.

After shrinkage, the dimensions of the log house continue to fluctuate slightly following seasonal changes in humidity.Therefore, window and door frames, as well as some other structures mounted in the house, are mounted on sliding mounts - casing, which do not prevent the vertical displacement of the crowns, but do not allow the occurrence of cracks or unintended loads.

The possibility of rot or fungus

Most of all damage to the lower rims of the house, as they are most in contact with moisture. To combat this ailment, there is a large number of anti-putrid antifungal impregnations. In order to prevent the destruction of the house, it is necessary to inspect its condition in time and take the necessary actions to protect it.

Insect damage

Ocified logs are plant material and are susceptible to insects. The control methods are the same as in the last paragraph - this is the use of insecticidal impregnation.

High sound conductivity

The sound conductivity of a house made of logs is higher than a house made of stone. Especially this point needs to be considered if it is supposed to build a house near busy roads.

Fire hazard

An oversized log burns very well, like any other wood material. Restoring a house after a fire is not possible.

Additional insulation is not possible

If you want to preserve the flavor of a log house, then you can not warm the walls. At the same time, the available thickness of the log house may not be enough for comfortable year-round living. It all depends on the region in which construction is planned. Therefore, before deciding on the materials for construction, be sure to find out the recommended standard wall thickness of wood for your region at home.

The disadvantages can be regarded as the features of a log house - a pronounced relief of the walls and the need to let the ends of the logs out of the corner locks. But the assessment of these features depends on the personal views of the homeowner. Often, logs are preferred for the sake of the traditional color of the chopped house.

Each advantage, and each disadvantage may have different values in the eyes of the builder, depending on the specific circumstances and personal preferences. Someone like chopping "in the paw", even corners and flat walls.

For some, the traditional look of a log house, with protruding logs, is valuable. Saving is important for someone, and someone is willing to overpay, if only to realize their vision of an ideal home. Weigh the pros and cons, and decide on the choice of material and type of home.