Condensing gas boilers - the principle of operation, advantages and disadvantages

The ever-increasing cost of energy has pushed scientists and engineers to create a new type of heat generator - a condensing boiler. When installed in a low-temperature heating system, the capacitor can show an efficiency of more than 100%. How do you manage to achieve this? What is the principle of operation of a condensing gas boiler? What are its advantages and disadvantages? After reading our article, you will learn about it all or almost everything.

Content:

The principle of operation of the condensing boiler

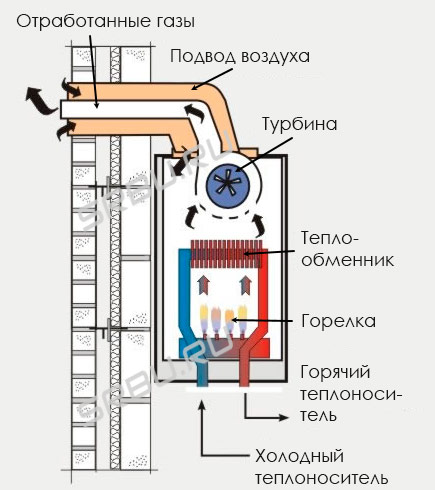

Condensing boiler is the younger brother of the most conventional gas convection boiler. The principle of operation of the latter is extremely simple, and therefore understandable even to people who are poorly versed in physics and technology. The fuel for the gas boiler, as its name implies, is natural (main) or liquefied (balloon) gas. During the combustion of blue fuel, as well as any other organic matter, carbon dioxide and water are formed and a large amount of energy is released. The generated heat is used to heat the coolant - industrial water circulating through the home heating system.

The efficiency of a gas convection boiler is ~ 90%. This is not so bad, at least higher than that of liquid and solid fuel heat generators. However, people have always sought to bring this indicator as close to the cherished 100% as possible. In this regard, the question arises: where do the remaining 10% go? The answer, alas, is prosaic: they fly out into the pipe. Indeed, the products of gas combustion leaving the system through the chimney are heated to a very high temperature (150-250 ° C), which means that 10% of the energy we lost is spent on heating the air outside the house.

Scientists and engineers have long been looking for the possibility of a more complete heat recovery, however, a method for the technological embodiment of their theoretical developments was found only 10 years ago, when a condensation boiler was created.

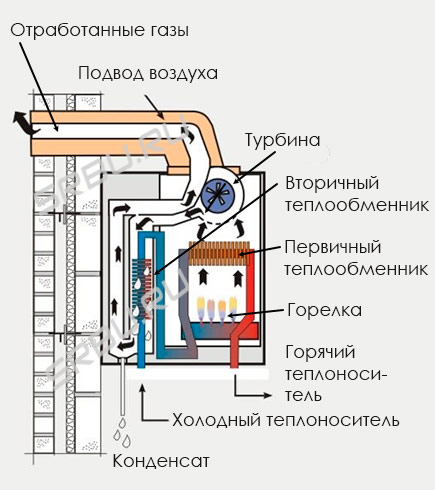

What is its fundamental difference from a traditional convection gas fuel heat generator? Having completed the main process of burning fuel and transferring a significant part of the heat released during this process to the heat exchanger, the condenser reaches the combustion gases to 50-60 ° C, i.e. to the point where the process of condensation of water begins. Already this is enough to significantly increase the efficiency, in this case, the amount of heat transferred to the coolant. However, this is not all.

Traditional gas boiler

Gas condensing boiler

At a temperature of 56 ° C - at the so-called dew point - water passes from a vaporous state to a liquid state, in other words, water vapor condenses. In this case, additional energy is released, which in due time was spent on the evaporation of water and in ordinary gas boilers is lost together with the volatilized vapor-gas mixture. A condensing boiler is able to “pick up” the heat generated during the condensation of water vapor and transfer it to the heat carrier.

Manufacturers of condensation-type heat generators invariably draw the attention of their potential customers to the unusually high efficiency of their devices - above 100%. How is this possible? In fact, there is no contradiction to the canons of classical physics. Just in this case, they use a different settlement system.

Often, evaluating the efficiency of heating boilers, they calculate how much of the heat released is transferred to the coolant. The heat "taken" in a conventional boiler, and the heat from deep cooling of the flue gases will give a total of 100% efficiency.But if we add here also the heat released during the condensation of the vapor, we get ~ 108-110%.

From the point of view of physics, such calculations are not entirely true. When calculating the efficiency, it is necessary to take into account not the released heat, but the total energy released during the combustion of a mixture of hydrocarbons of a given composition. This will include the energy spent on transferring water to a gaseous state (subsequently released during the condensation process).

It follows that a coefficient of performance greater than 100% is just a tricky move by marketers who exploit the imperfection of an outdated calculation formula. Nevertheless, it should be recognized that the condenser, unlike a conventional convection boiler, manages to "squeeze" all or almost all out of the fuel combustion process. The positive points are obvious - higher efficiency and lower consumption of fossil resources.

The device of the main components of the condensing boiler

From a structural point of view, the condensation boiler is not much, but still different from the usual gas boiler. Its main elements are:

- a combustion chamber equipped with a burner, a fuel supply system and a fan for pumping air;

- heat exchanger No. 1 (primary heat exchanger);

- a chamber for further cooling the gas-vapor mixture to a temperature as close as possible to 56-57 ° C;

- heat exchanger No. 2 (condensing heat exchanger);

- condensate collection tank;

- chimney for the removal of cold flue gases;

- a pump for circulating water in the system.

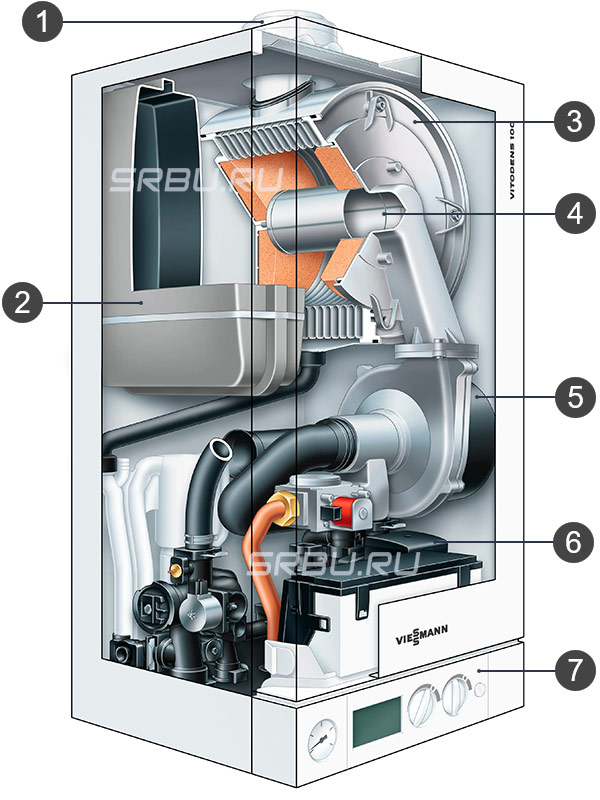

1. Chimney.

2. Expansion tank.

3. Heat transfer surfaces.

4. Modulated burner.

5. Burner fan.

6. Pump.

7. Control Panel.

In the primary heat exchanger coupled to the combustion chamber, the evolved gases are cooled to a temperature significantly above the dew point (in fact, this is what conventional convection gas boilers look like). Then the flue mixture is forcibly directed to the condensation heat exchanger, where it is cooled to a temperature below the dew point, i.e. below 56 ° C. In this case, water vapor condenses on the walls of the heat exchanger, "giving the last". Condensate is collected in a special tank, from where it flows down the drain pipe into the sewer.

Water, which acts as a coolant, moves in the opposite direction to the motion of the vapor-gas mixture. Cold water (return water from the heating system) is preheated in a condensing heat exchanger. Then it enters the primary heat exchanger, where it is heated to a higher temperature specified by the user.

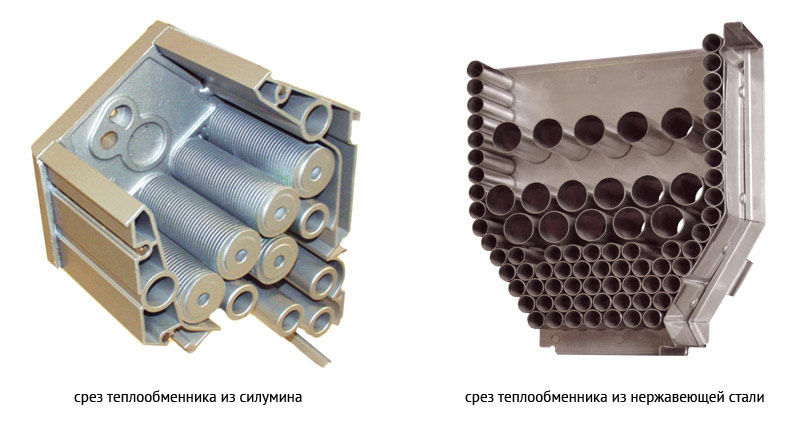

Condensate - alas, not pure water, as many believe, but a mixture of diluted inorganic acids. The concentration of acids in the condensate is low, but taking into account the fact that the temperature in the system is always elevated, it can be considered an aggressive liquid. That is why in the manufacture of such boilers (and primarily condensing heat exchangers) acid-resistant materials are used - stainless steel or silumin (aluminum-silicon alloy). The heat exchanger, as a rule, is made cast, since welds are a vulnerable spot - this is where the process of corrosion destruction of the material begins in the first place.

Steam should be condensed precisely on the condensing heat exchanger. Everything that went further into the chimney, on the one hand, is lost for heating, and on the other, it destructively affects the material of the chimney. It is for the latter reason that the chimney is made of acid-resistant stainless steel or plastic, and a slight slope is attached to its horizontal sections so that the water formed during the condensation of the insignificant quantities of steam that nevertheless fall into the chimney is drained back into the boiler. It should be taken into account that the flue gases leaving the condenser are very cooled, and everything that has not condensed in the boiler will necessarily be condensed in the chimney.

At different times of the day, a different amount of heat is required from the heating boiler, which can be regulated using a burner. The burner at the condensing boiler can either be modulated, i.e. with the possibility of a smooth change in power during operation, or non-simulated - with a fixed power. In the latter case, the boiler adapts to the requirements of the owner by changing the frequency of turning on the burner. On most modern boilers designed for heating private houses, simulated burners are installed.

So, we hope you have got a general idea of what a condensing boiler is, how it is built and by what principle it works. However, most likely, this information will not be enough to understand whether you should personally purchase such equipment. To help you make this or that decision, we will tell you about all the advantages and disadvantages, pluses and minuses of a condensing boiler, comparing it with a traditional convection one.

The advantages of a condensing boiler

The list of advantages of the condensing boiler is impressive, which ultimately explains the growing popularity of this type of heating equipment:

- Fuel economy compared to a conventional convection boiler, it can reach 35%.

- Emission reduction in the transition from traditional gas models to condensation ones, it is estimated at an average of 70%.

- Low flue gas temperature makes it possible to install plastic chimneys, which are much cheaper than classic steel.

- Low noise increases the comfort level of people living in the house.

Let's talk about some of the listed advantages of condensing boilers in more detail.

Fuel economy when used in low temperature systems

Fuel consumption directly depends on the power of the equipment and the load assigned to the heating system. For heating a house with an area of 250 m2 a 28-kilowatt condensing boiler with a maximum gas consumption of 2.85 m will be enough3/ h A classic boiler of the same power will consume 3.25 m3/ h Provided that the boiler is operated for six months out of twelve, you will save about 3000 rubles a year. (at existing prices for main gas for Russian consumers). It is probably difficult to call such a saving significant - it will not even cover the differences in the cost of annual maintenance of boilers.

But let’s take a look at the situation through the eyes of the average European consumer, who costs four to five (or even more) times the price of natural gas. The amount of savings in this case is already about 300 euros, and it’s worth fighting for.

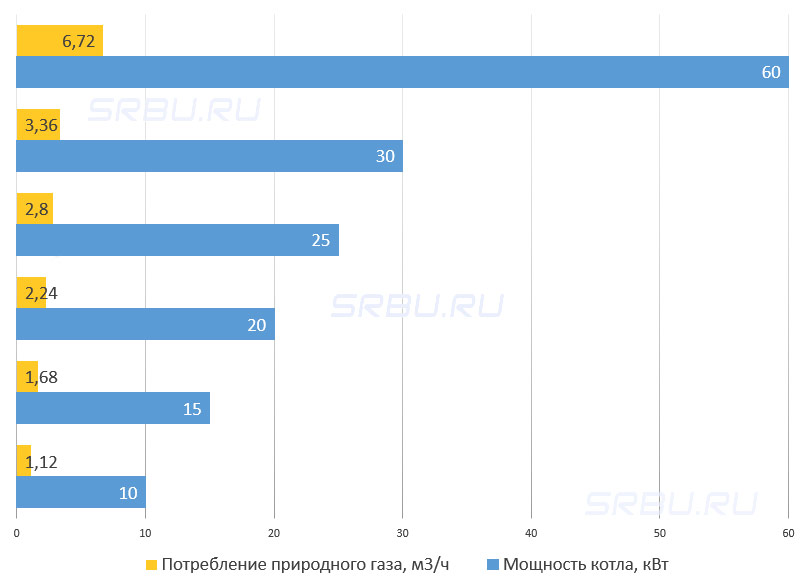

Gas consumption in condensing boilers of various capacities:

Emission reduction

During the combustion of fossil fuels, carbon dioxide is formed, which, when reacted with water, gives carbon dioxide. In addition, in any fuel there are always impurities of compounds of sulfur, phosphorus, nitrogen and a number of other elements. In the process of combustion, corresponding oxides are formed from them, which, when combined with water, also produce acids.

In conventional convection boilers, water vapor with an admixture of acids (carbonic, sulfuric, nitric, phosphoric) is released into the atmosphere. Condensing boilers do not have this drawback: acids remain in the condensate. However, given the problems with condensate utilization, the notorious environmental friendliness of this equipment can be called into question.

Cons condensing boiler

The condensation boiler, for all its advantages, cannot be called ideal heating equipment, because it is not without its drawbacks:

- high price;

- the high cost of the heat exchanger (and, as a consequence of this, the need to carefully monitor the condition of the entire heating system);

- inappropriateness of use in high-temperature systems;

- difficulty condensate recovery;

- sensitivity to air quality.

Price

For additional percent of thermal energy you have to pay.Technically, a condensing boiler is more complicated and therefore more expensive. The cost of a good household capacitor from a well-known manufacturer is several times higher than the cost of a classic unit of the same power. Of course, such equipment is purchased for more than one decade, which means it makes sense to give preference to innovative technologies that increase operating comfort.

Conventionally, all models of condensing boilers can be divided into three price categories - premium, middle and economy class:

1. The premium class is designed for a few buyers. Premium condensation boilers include, for example, models of German brands. This equipment is efficient in operation and convenient in operation, meets European environmental standards, made of high quality materials. “Premium” boilers have many useful functions that significantly increase the level of comfort during their operation: programming of operating modes (for example, maintaining the room temperature at a minimum level in the absence of hosts or a slight decrease in temperature at night), weather-dependent regulation, intelligent interaction with other heat generators , remote control using a special program on a mobile phone, etc. The only negative is the high price.

2. The middle class includes cheaper goods, but with slightly more modest consumer qualities. These are economical and environmentally friendly units that meet all the requirements and provide high performance. They are distinguished by a wide range of functions, equipped with an automatic control system that independently changes parameters depending on the temperature of the coolant and air in the room.

3. Economy class is designed for those who, for the sake of economy, are ready to put up with a lower level of comfort. Bulk goods always lead in sales. The leading positions in the market of economy class condensing boilers belong to Korean and Slovak companies. Their products are two or more times cheaper than premium models. Another advantage of this equipment is its adaptability to Russian operating conditions. Inexpensive capacitors with simple functionality calmly endure power outages and pressure drops when expensive automation stops working.

Assessing your financial capabilities, you must take into account the inevitable costs of installation and commissioning of equipment, which will also cost you very, very expensive.

It should not be forgotten that during operation, the condensing boiler provides gas savings. However, this savings is so ghostly that the investment will not pay off soon. This means that before buying condensation heat, it is worthwhile to make a preliminary assessment: whether the cost of the saved fuel will justify the high price of the equipment.

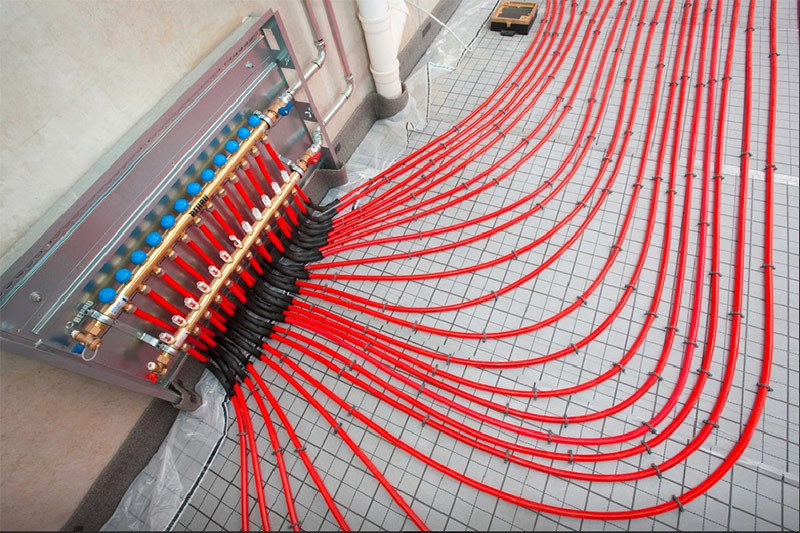

A positive economic effect from the acquisition of such a boiler should be expected only under certain conditions - if it is installed in a new (read “under construction”) house designed for permanent residence with an organized low-temperature heating system of underfloor heating. Moreover, the magnitude of the effect directly depends on the average winter temperature, i.e., on the region where the house is located (the principle is simple: the more heat is needed, the more sense there is in such a technique).

The high cost of the heat exchanger used

A heat exchanger is a technically complex and expensive element. In the event of its failure, you, as they say, "get on the headstock." For the money that you spend on buying a new heat exchanger and paying for the work to replace it, you could easily purchase a new convection boiler of the same capacity.

From this it follows that it is necessary to carefully monitor the condition of the heat exchanger. It will be extremely difficult to rinse it when it clogs. When installing a condensing boiler, it is necessary to audit the entire heating system - there should be no rusty pipes and radiators in it.

The safety of the heat exchanger also depends on the quality of the coolant used. Water should be soft, otherwise the tubes will quickly overgrow with scum from the inside. The presence of rust in the water, foreign suspensions, calcium and iron salts is unacceptable.

Since the condensate contains acids, the heat exchanger must be able to withstand their effects. Most often, heat exchangers are made of silumin and high-quality stainless steel. Silumin heat exchanger is produced by casting metol. Due to the lower cost of the material and production technology, these heat exchangers are cheaper than stainless steel heat exchangers. But there is a drawback to these heat exchangers - they are less resistant to aggressive acidic environments.

Stainless steel heat exchangers are produced by welding individual parts. The final cost of such heat exchangers is higher than silumin. However, they better resist acidic environments and add reliability to equipment.

Inappropriate use in high temperature systems

The promised efficiency of 108-110% can not always be obtained - the real figure depends on the heating system. There are two fundamentally different types of heating systems - high-temperature and low-temperature. They differ in the temperature range of the coolant at the inlet and outlet of the heat generator.

In conventional high-temperature heating systems, the ratio of the temperature of the supplied water to the return water is usually 75-80 ° C to 55-60 ° C. A system with a condensing boiler is effective only in low temperature mode, i.e. when the ratio of the supply and return temperatures is 50-55 ° C to 30-35 ° C. This ratio is ideal if the heating of the home is carried out using underfloor heating. Otherwise, to warm the room, it will be necessary to install additional radiators with a 2.5-3 times increase in useful surface area, designed for a coolant temperature of not higher than 50 ° C.

The efficiency of the condensing boiler is determined primarily by the inlet temperature of the coolant. This is explained simply: the lower the temperature of the water in the return circuit, the more intense the condensation occurs. The boiler efficiency in a low-temperature heating system (inlet / outlet temperature is approximately 30/50 ° C) can reach those very 108-110%. If such a boiler is made to function in a high-temperature system (60/80 ° C), then there will be no condensation, and the efficiency will drop to 98-99% - this is more than with conventional convection boilers, but less than it could be.

Thus, if you want to extract the maximum benefit from the capacitor, the decision to install it must be taken at the design stage of the house. If you buy such a boiler for an existing house with an existing heating system, this means the inevitable reconstruction of the building with the replacement of a high-temperature radiator heating system with a low-temperature system of underfloor heating (and such a large-scale repair is again a considerable expense, and the economic effect of the whole undertaking is lost).

Condensate recovery difficulty

The use of a condensing boiler involves the disposal of condensate. Moreover, the latter is formed in considerable quantities - one liter of a cubic meter of burned gas. For example: a boiler with a capacity of 25 kW per hour consumes about 2.8 m3 gas, i.e., in just one hour of its operation, slightly less than 3 liters of condensate will be released, per day - 70 liters.

Recall that condensate is a solution of acids, which means that the question of where to put it is not at all idle. It’s good if your house is connected to a centralized sewage system. Even according to strict European standards, boilers with a capacity of up to 28 kW do not require special disposal of condensate. It is assumed that such a quantity of condensate is sufficiently diluted with domestic wastewater so as not to harm the sewer pipes.

But what do owners of private houses with autonomous sewer do? It is impossible to pour into a septic tank - beneficial (and expensive) bacteria will die.Pouring onto the ground is unacceptable - soil salinization will occur, and over time, nothing will grow in this place. It is extremely difficult to transport 70 liters daily for disposal. There is only one way out - to provide for its own separate system to neutralize the acids contained in the condensate. In the West, where the requirements for compliance with environmental standards are more stringent than ours, a catalytic converter is automatically purchased when a condensing boiler is installed.

Sensitivity to air quality

An important point that you should pay attention to if you want your boiler to function normally is the removal of combustion products and the access of combustion air.

One of the differences between condensation and convection boilers is the use of a closed combustion chamber. Convection boilers take air from the room, condensation boilers from the street. In the first, natural air circulation (convection) is used to saturate the air-fuel mixture with oxygen, and in the second, a fan is provided that pumps air into the burner. The removal of products of combustion in them, by the way, is also carried out forcibly. Air masses are circulated, as a rule, through a coaxial chimney, which is a pipe-in-pipe construction. The intake air moves through the external cavity of the chimney, the exhaust products of combustion - through the internal.

From all this it follows that capacitors must be very sensitive to the quality of the intake air. The presence of a noticeable amount of dust in the air leads to rapid wear of the turbine (fan).

Of great importance for the normal functioning of the condensing boiler is not only cleanliness, but also the outdoor temperature. If air is accessed into the system through a coaxial chimney pipe, then, as practice shows, the inlet air duct in winter, in frosts, can freeze, because the temperature of the exhaust flue gases is quite low, and they are not able to warm the chimney walls. This leads to a decrease in the oxygen supply necessary for burning fuel, and, as a result of this, to a decrease in the efficiency of the equipment.

To prevent this from happening and you do not have to periodically heat the pipes to free them from ice, the calculation of the system, its installation, start-up and configuration should be carried out by certified service specialists. To adjust the parameter responsible for the intake of air in the amount necessary for burning fuel in a boiler of a given power, they use a gas analyzer. Without such special equipment, the required efficiency from the boiler cannot be achieved. In addition, residents of areas with harsh climatic conditions, when deciding on the installation of a condensing boiler, should seek clarification from the manufacturer's representatives about the possibility of operating such equipment at a given range of local outdoor temperatures.