Choosing a gas boiler for heating a house - detailed instructions

The individual heating system is becoming more widespread in our country: it is easier to switch to independent heating of your home than to invest in building new or upgrading old boiler houses. There are several ways to heat a private house, but the most economically viable is the use of a gas-fired boiler.

The heating equipment available on the market today is striking in its diversity, which leads potential buyers to some confusion. To understand what kind of gas boiler to choose, you should spend a little time studying the issues of the device of this type of heat generators, the principle of their operation, the purpose of individual elements, etc.

Only in this way you can understand what really suits you. The selection process will become simpler and more understandable, and in addition, you can save money on the purchase of the unit and its subsequent operation.

Content:

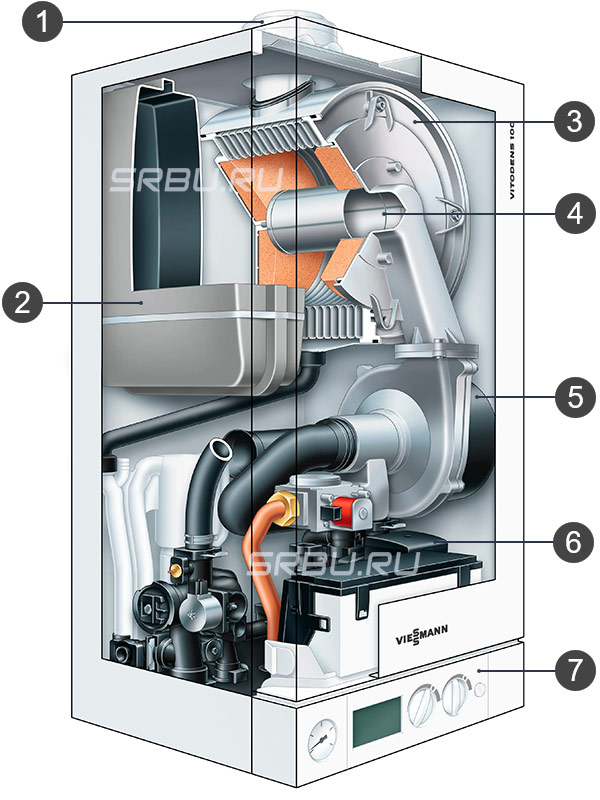

The device of a gas heating boiler

All gas boilers, regardless of the level of their "tricked out", have a single principle of operation and a similar device. Let’s figure out what is hidden under the panel of the body of any gas boiler.

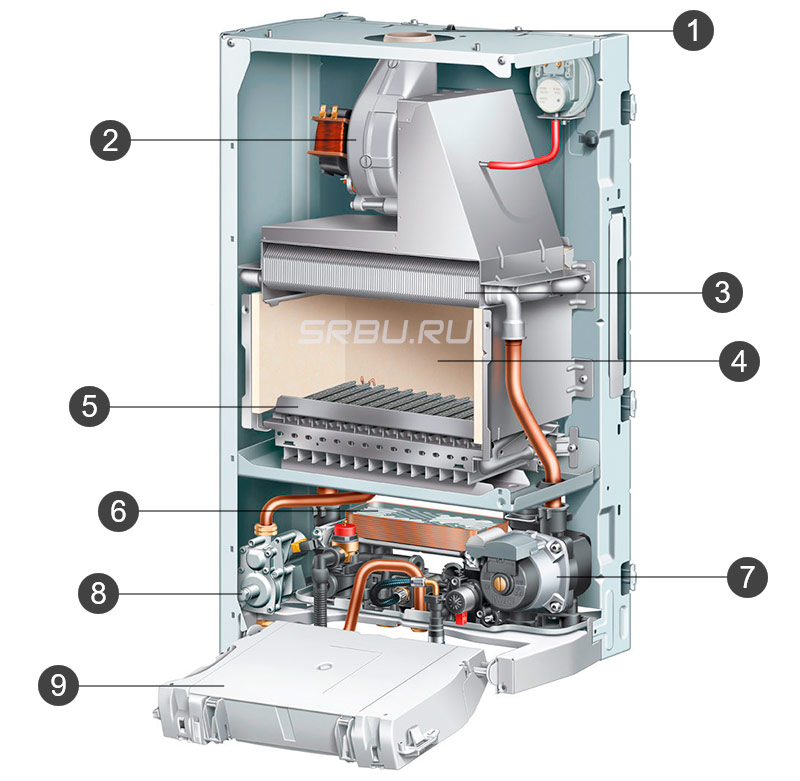

The main structural elements of a gas boiler

1. exhaust gas discharge;

2. air blower;

3. heat exchanger;

4. the combustion chamber;

5. burner;

6. DHW heat exchanger;

7. circulation pump;

8. gas valve;

9. Control block.

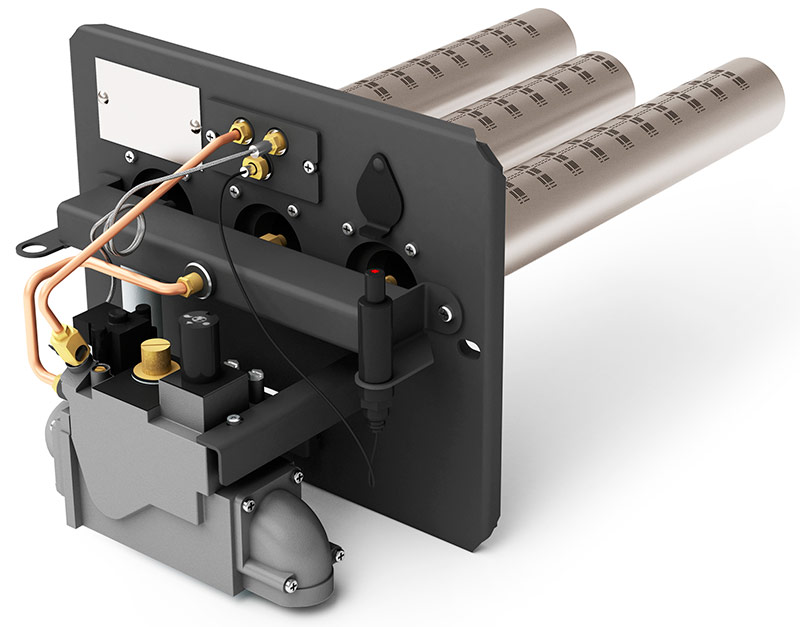

Burner

The burner can safely be called the heart of a gas boiler. It is here that the combustion of fuel occurs with the release of thermal energy. According to the method of regulating the flame intensity, the burners are divided into:

- single stage;

- two-stage;

- modulated.

The former have only one operating mode, the latter have two (maximum and economical), while the latter can be continuously adjusted in a fairly wide range from 10 to 100%, which makes it possible to fine-tune.

Modulated burners are much more convenient in operation, allow maintaining the set temperature with minimal deviations and provide fuel economy. For these reasons, most gas boilers manufactured today are equipped with just such burners.

By the method of igniting a gas-air mixture, all burners can be divided into devices with manual ignition (piezo ignition) and with automatic. The first can be found only in the simplest and cheapest boilers. Modern gas boilers are designed to heat a house in an autonomous mode: their work is controlled by automation, and installing burners with manual ignition on them is impractical.

Those who choose a gas boiler, it is important to know that for the main (natural) gas and liquefied propane-butane mixture supplied in cylinders, different burners are needed. In some boiler models, but not all, it is possible to replace the nozzle with a gas suitable for another type.

Burner gas boiler with fittings and automation.

The combustion chamber

The combustion chamber in which the burner is located may be closed or open type. An open combustion chamber consumes air from a room, a closed one requires additional installation of a special air intake.

Gas fittings

Gas fittings are designed to control the gas supply to the burner. The signal from the control unit opens or closes a valve that blocks the movement of gas through the supply pipes of the gas pipeline.

Three-way valve

The three-way valve is used in double-circuit gas boilers. He switches the system to the mode of generating hot water for domestic hot water and vice versa - to the heating mode. The valve operates at the moment of opening / closing of the water tap.

Chimney

The chimney is designed to exhaust combustion products. The smoke exhaust system can be either forced or natural draft.

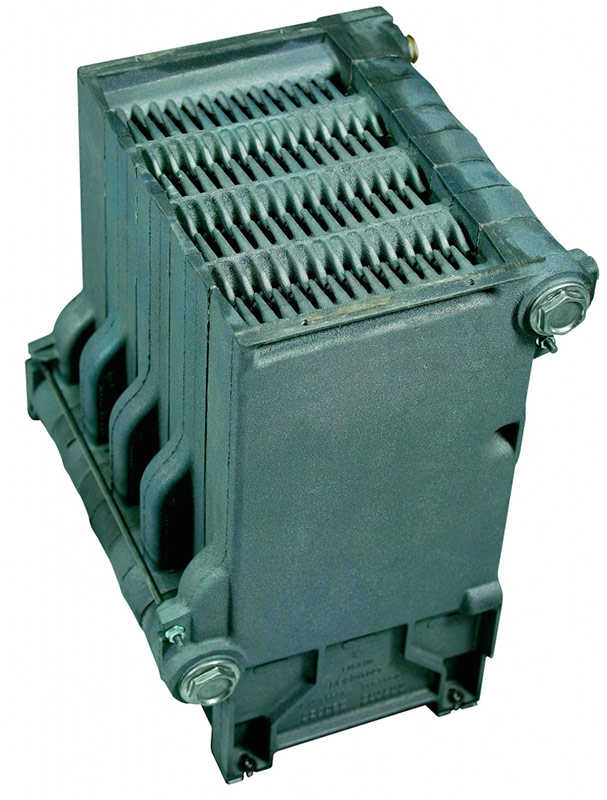

Heat exchanger

The heat exchanger performs the function of transferring heat generated during the combustion of gas to the coolant. In its simplest form, it is a coil along which the heating medium of a heating system moves, with many tightly mounted metal plates.

The longer the coil pipe and the greater the number of plates mounted on it, the greater the heat transfer. The material from which the heat exchanger is made is determined primarily by the method of mounting the gas boiler. In wall-mounted devices, as a rule, copper or stainless steel — relatively light metals — are used for these purposes.

Steel heat exchanger of a gas boiler.

In outdoor models, heavy cast iron heat exchangers are often installed, since cast iron is not subject to corrosion (which means that it is very durable) and holds heat well. In addition to the main heat exchanger located above the burner, some gas boilers install an additional one designed to heat water for the domestic hot water system.

Cast iron gas boiler heat exchanger.

Circulation pump

The circulation pump makes the coolant continuously move through the pipes of the heating system. Thanks to the pump, heat is distributed faster throughout the entire house.

Expansion tank

The expansion tank is designed to compensate for the increase in the volume of the liquid that acts as a coolant when it is heated. The volume of the tank depends primarily on the volume of the coolant in the heating system (~ 10% of the volume of the entire liquid). The tank is located either in the boiler itself or in the immediate vicinity of it.

Security system

The safety system includes a pressure gauge, a safety valve and an air vent. A pressure gauge controls the pressure in the system. If it “exceeds” the upper limit of permissible values (according to Russian standards - 3 bars), the safety valve will reset. The air vent is needed to remove air from the system, which is always dissolved in water and antifreeze in a certain amount, and which, when the temperature rises, starts to come out of the liquid in the form of bubbles.

Control block

The control unit bears the function of monitoring the status of the various components of the system and controlling the burner, circulation pump, valves and other elements. Electronics through various sensors monitors the temperature in the rooms and in the circuits of the heating system, the pressure of the coolant, the presence of flame and other process parameters. The simplest control unit maintains the temperature set by the user.

In more complex and expensive models, it can be programmed for various modes of operation of the boiler (for example, a slight decrease in temperature at night, the “master at work” mode, when the boiler maintains a low temperature during the whole working week and only reaches full power at full power in the evening, that is, by the time the tenants return home, the “host on departure” mode, in which the room temperature is maintained at the minimum acceptable level, preventing the coolant from freezing in the pipes, etc.).

When installing temperature sensors outside the building, the control unit can cause the boiler to work even in weather-dependent mode, which can significantly save fuel. In the event of an emergency, the automation itself will turn off all equipment.

The ability to connect the control unit to the remote control is available even for relatively simple boilers.More complex models can also be controlled via the GSM channel. Of course, the “smarter” the gas boiler, the more expensive it is, but the high cost is justified by the increased efficiency and operating comfort.

How to choose the right type of gas boiler

When deciding which gas boiler for heating a private house is better to choose, you should not focus solely on price. There are other selection criteria, no less important. And before you go to a company engaged in the supply and installation of heating equipment, you need to get at least a general idea of what gas boilers are. This will help you avoid making mistakes that can cost you quite a bit.

Wall or floor gas boiler

By the method of installation, all gas boilers are divided into wall and floor. The main difference between these two types is the dimensions. All other differences - power, a number of other technical parameters, cost - can be considered as a consequence of the first.

Wall mounted models are compact and lightweight. As a rule, they do not even have a separate room for such devices, placing them in the kitchen or in the bathroom. Wall-mounted boilers are distinguished by relatively small capacities, which is quite predictable given their modest dimensions. As a result, they do not allow heating a large area of a house. The main advantage of wall-mounted gas boilers is lower cost.

Wall mounted gas boiler.

The weight of the average floor boiler significantly exceeds 100 kg. Typically, such units are placed in a boiler room. Most floor models have an open type combustion chamber, which means that high-quality forced ventilation must be mounted in the room, ensuring a constant flow of air.

Floor gas boilers on average are much more powerful than wall-mounted: they can be used to heat a fairly large country house. Another advantage of floor heating systems is the longevity of operation. This is primarily due to the use of more reliable materials for the manufacture of their individual structural elements.

So, for example, in floor units, as a rule, a cast-iron heat exchanger is installed, but not steel, as in wall-mounted models. Cast iron, as you know, is less susceptible to corrosion, which means it will last you longer. Of course, cast iron is much heavier than stainless steel, but for floor boilers, unlike wall-mounted boilers, a lot of weight is not a problem.

Floor gas boiler.

Of course, a powerful and reliable floor unit will cost you more than a wall unit. In addition, an expansion tank and circulation pumps are often not included in the set of floor models - these elements of the system will have to be purchased separately.

Single-circuit or double-circuit gas boiler

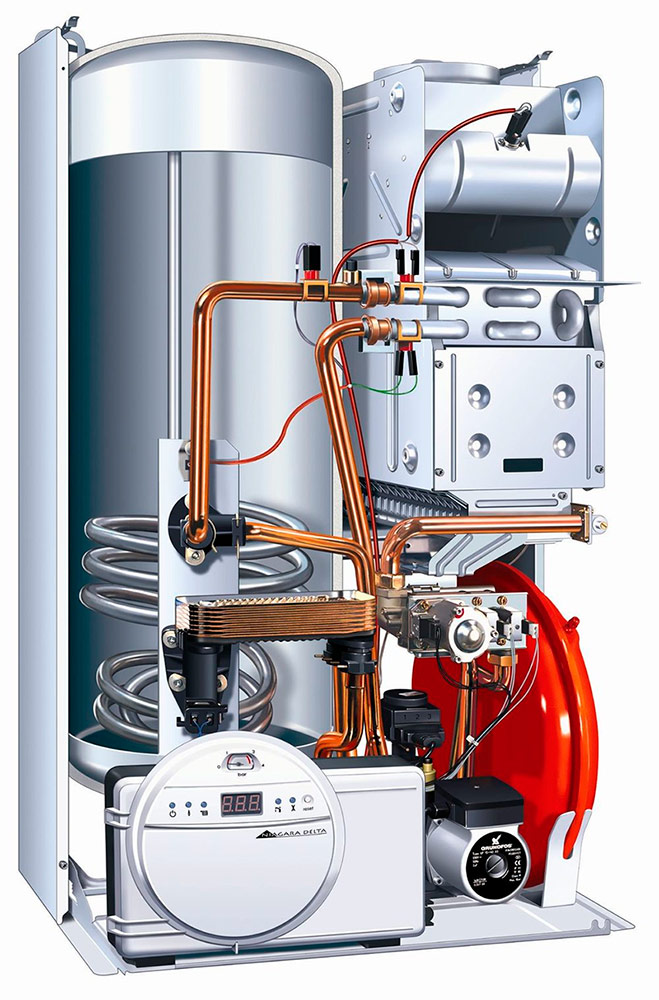

For a comfortable stay in a country house, it is required not only to heat the premises, but also to provide water heating for domestic needs. Of course, in addition to a heating gas boiler, you can purchase a gas or electric boiler. However, there is a simpler solution - a double-circuit boiler. It has two heat exchangers connected to two highways: one circuit is responsible for heating, the other for hot water supply.

Note that the second heat exchanger is located far from the burner and is not heated by a flame, but by the heat carrier heated on the primary heat exchanger. The flow of coolant through the heating circuit at the time of operation of the hot water supply is suspended. It follows from this that, despite the presence of two circuits, work simultaneously in two directions, i.e. provide hot water and heat the room, such a boiler can not.

And this in turn means that while you take a shower or wash the dishes, your batteries slowly cool down. True, practice shows that in a house of a small area, where hot water is consumed in reasonable quantities, this is almost imperceptible.

Providing residents of the house with hot water by means of a double-circuit gas boiler can be implemented in two ways: using a flowing water heater or an integrated tank. The first option is suitable only for those who do not spend more than 10-15 liters of hot water at a time.

In the second option, you can count on large volumes. The capacity of the built-in tank is usually 30-60 liters: this is enough to take a quick shower without experiencing any discomfort.

Sectional boiler with integrated boiler.

If you have a large family and, accordingly, the analysis of hot water is increased, it is better to install a single-circuit boiler and attach a 100- or even 200-liter indirect heating boiler to it. The latter is a large insulated metal tank, along the coil of which moves the coolant of the heating system.

For the summer period, the circulation of the coolant through the heating system is blocked so that only water for domestic hot water is heated.

Boiler with indirect heating boiler.

Which gas boiler to choose - single-circuit or double-circuit, depends on the amount of hot water consumed by the residents and on the area of the premises that need to be heated. A double-circuit boiler is a good option for a modest-sized home: there is no need to install a separate heating device and a separate water heater for hot water, and this gives you the opportunity to significantly save space.

If the house is large, it has several points of draw-in, and the family size is quite large, then preference should be given to a single-circuit boiler with a separate indirect storage boiler. You can also think about installing a dual-circuit gas boiler and a storage boiler with parallel electric heating: a similar system will allow you to have hot water even if any of the appliances breaks down.

Convection or condensing gas boiler

All gas boilers are divided into convection and condensation. How do they differ, and which one to give preference?

The efficiency of a traditional convection boiler is ~ 90%. In principle, this is a good indicator, but the reasonable question arises: where do the remaining 10% go? The answer, alas, is simple: fly into the pipe. The gas combustion products leaving the system through the chimney are heated to 150-200 ° C (for some modern low-temperature models - up to 100 ° C), which means that 10% of the energy lost is spent on heating the air outside the house.

The condensing boiler is able to cool the gaseous products of combustion up to 50-60 ° C and thereby significantly increase the amount of heat transferred to the coolant. But that is not all. At a temperature of 56-57 ° C, condensation of water vapor contained in the smoke occurs. In this case, additional energy is released. The condensing gas boiler "picks up" and transfer this heat to the coolant.

Condensing gas boiler device

1. Chimney.

2. Expansion tank.

3. Heat transfer surfaces.

4. Modulated burner.

5. Burner fan.

6. Pump.

7. Control Panel.

So, a condensing gas boiler is able to "take" much more energy from a burning gas than a convection model. In other words, its efficiency is significantly higher. Does this mean that you should forget about less economical convection boilers and initially tune in to the purchase of condensing. Before making a final decision, it makes sense to talk about the shortcomings of such an ideal unit at first glance.

Water vapor, condensing into a liquid, “grabs” with itself the gases also contained in the products of combustion. First of all, we are talking about carbon dioxide, although this also applies to sulfur oxides, phosphorus, nitrogen, and some other elements present in small amounts.

When interacting with water, these gases give the corresponding acids - carbonic, sulfuric, phosphoric, nitric, etc.From this it follows that the condensate formed during the operation of the boiler and accumulated inside it is not pure water, but rather a corrosive liquid.

And here we are faced with two problems at once:

- At firstso that the reactive condensate does not corrode the boiler elements with which it is in contact, they must be made of acid-resistant materials (for example, aluminum-silicon alloy or acid-resistant stainless steel). This also applies to the chimney, because part of the water vapor will still fly away with the smoke and condenses there. The heat exchanger must be cast, as welds are one of the most vulnerable places. All this increases the cost of the unit even more.

- Secondly, the question always arises of the disposal of accumulated condensate. Draining a chemically active liquid into the sewers is strongly discouraged, which means you will need to purchase a separate system to neutralize acids and consumables for it.

There is another, more significant limitation on the use of condensing boilers. The efficiency of such heat generators is determined by the temperature range of the coolant at the inlet and outlet. The fact is that there is only one way to cool flue gases - to take heat from them and transfer it to the water, which acts as a coolant.

1. If your house uses a high-temperature heating system, i.e. if the premises are heated by means of traditional radiators, the ratio of the temperature of the water supplied to the system and the water in the return circuit should be 75-80 ° C to 50-60 ° C. It is highly doubtful that at such temperature ranges the boiler will be able to effectively cool the gases to the temperature of water condensation.

2. If the premises are heated with underfloor heating, i.e. your house is equipped with a low-temperature heating system, the ratio of the temperature of the coolant and the “return” will be in the region of 50-55 ° C to 30-35 ° C. Under such conditions, the flue gas will be cooled sufficiently to allow condensation to occur in the boiler.

From the foregoing, a simple conclusion can be made: a condensing boiler is effective only in combination with a low-temperature heating system. Otherwise, its efficiency will not differ much from the efficiency of a traditional convection boiler, which means that the money spent on the purchase of expensive equipment will be wasted.

Gas boilers with open or closed combustion chamber

We have already mentioned that the combustion chamber of a gas boiler can be open or closed. In the first case, the air necessary to maintain the gas combustion process enters the burner directly from the room where the boiler is located, in the second case it is forcedly forced by the fan through the air intake pipe or through the coaxial chimney pipe.

Condensing boilers, which we spoke about above, always have a closed combustion chamber.

Boilers with closed chambers are more efficient, their efficiency is higher. In addition, they are less sensitive to pressure drops in the gas line and continue to work effectively even with reduced pressure in the gas pipeline.

But such boilers are more expensive than models with an atmospheric burner, and they need electricity to operate the fan. However, the main drawback of gas boilers with a closed combustion chamber is, perhaps, the noise of their work.

It is worth mentioning another type of gas boilers - parapet. They have a closed combustion chamber, air is supplied through a coaxial pipe, but without the use of a blower fan. The power of such units is less, but at the same time they are non-volatile and noiseless.

Those who are going to install a gas heating boiler in their home should understand that to ensure its normal operation it is necessary to ensure not only the removal of the combustion products of the fuel, but also the air flow, regardless of the type of combustion chamber used in it.The main product of gas combustion in the boiler, which does not have enough air, will be not a relatively harmless carbon dioxide, but a deadly carbon monoxide.

If we are talking about a model with an open chamber, it will be enough to install one chimney, however, the room must have good forced ventilation. The latter, by the way, is the reason for significant heat losses in the winter, and this should be taken into account when calculating the required boiler capacity.

For boilers with a closed combustion chamber, outside air is supplied through a pipe separate from the chimney. In principle, it can be one pipe, but coaxial, which is a “pipe in pipe” design: the exhaust flue gases move along the internal cavity of the pipe, and the supplied air moves along the external.

Coaxial chimney.

Since we are talking about chimneys, it will not be amiss to say a few words about the rules for installing the chimney:

- Do not try to save on pipes. For metal pipes used for the installation of the chimney, resistance to condensation and burnout is important, plastic must have sufficient heat resistance and reliable seals in the joints. Cheap pipes that are not designed for gas boilers are unlikely to meet these requirements, which means that in a couple of years you will have large-scale work to replace the chimney.

- The angle of the horizontal sections of the chimney depends on the type of gas boiler. For convection boilers, the slope should be made towards the street, for condensation boilers - towards the boiler itself.

- The maximum permissible chimney length from a coaxial pipe is 5 meters, and each bend reduces this value. That is why the coaxial tube, as a rule, is simply led out through the wall. For "single" pipes there are no such restrictions.

- The chimney in a natural draft system must be at least 4 meters high.

How to calculate the power of a heating boiler

The cost of a gas boiler is directly proportional to its power. And here we are faced with a dilemma. On the one hand, you want to have equipment with a power reserve so that you don’t freeze in your own house on especially cold winter days, on the other hand, you really don’t want to overpay. How not to make a mistake when choosing a gas boiler for this parameter?

Of course, experts will best deal with this issue. However, you can make a preliminary assessment of the required capacity of the climate equipment yourself. To do this, it will be enough to use the ten-to-one rule.

According to this rule, empirically derived, 1 kW of thermal energy is required to heat 10 square meters of a room. For example, for a house of 100 square meters, you need a boiler with a capacity of 10 kW. At the same time, it is assumed that the house is well insulated, the ceiling height in it does not exceed 3 meters, and the temperature in the street is kept at –25 ... –30 ° С.

Accordingly, if you live in a region that is characterized by harsher winters or the quality of home insulation leaves much to be desired, the boiler capacity calculated using this formula will not be enough. An experienced engineer will take into account all these nuances when developing a project. If you want to do the calculation yourself, just lay the power reserve at 10-20 percent.

It should be borne in mind that these calculations are suitable only for single-circuit boilers that provide home heating. If you intend to install a double-circuit boiler, which will not only warm your home, but also prepare water for domestic hot water, then the power of this unit should be significantly higher.

In order for the boiler to be able to dispense 10 l of water with a temperature of 35 ° С per minute, which is enough for a comfortable shower, its power should be at least 24 kW. If the house has two draw-off points, the lower limit of the required power will rise to 28-30 kW. If your house has two kitchens, three bathrooms and many households, it makes sense to think about installing two gas boilers.

Some additional nuances

Before making the final choice, potential owners of gas boilers should take into account a number of important points directly related to the purchase, installation and operation of this heating equipment.

1. Gas is the cheapest fuel today. However, it should be noted that bringing a gas pipe to the house is quite expensive. The costs of connecting to the highway are estimated in hundreds of thousands of rubles.

2. In some cases, it can be simply impossible to supply a gas pipe for technical reasons. There is a way out of this situation: you can dig a gas holder in the area adjacent to the house - a container for storing liquefied gas.

However, take into account that liquefied gas is more expensive than main gas, and the gas storage needs to be inspected once every 10-20 years (which is expensive and time-consuming) or replaced altogether.

3. The cost of a gas boiler on average varies from a couple of tens to a couple of hundred thousand rubles, depending on the type, capacity and other parameters. However, having such an amount in your pocket, do not rush to purchase.

In addition to the boiler itself, pipes and fittings for heating circuits, pipes for the chimney, automation and control devices, etc. will be needed. etc. You will have to spend a lot of money on installing the entire system.

4. Since possible fluctuations in the cost of the boiler against the background of other costs for a turn of the heating system can be considered insignificant, it makes no sense to chase cheap models. “No name” boilers, as a rule, function accordingly, and problems usually arise when they need to be repaired.

5. A big plus when choosing a particular brand of gas boiler will be the presence of the service department of this brand in your region.

6. The adjustment and first start-up of the gas boiler must be carried out by specialists. Installation of equipment must also be carried out by certified craftsmen.

Even if you can cope with this task on your own, a qualified employee will have to check everything and issue a permit for operation. If this condition is not met, the manufacturer will be entitled to refuse your subsequent warranty service.