Which gas boiler is best to use - an overview of the types and models of equipment

From this review you will learn what types of boilers exist and in which cases this or that type of heating equipment is needed. In addition, we present to your attention a rating of the best gas boilers for a private house, based on user reviews and taking into account the main characteristics of the equipment.

Wall or floor gas boiler

According to the installation method, gas boilers are of two types:

- wall mounted;

- outdoor.

The first variety involves mounting to the wall, so it has a small mass - not more than 80 kg. The power of such units can reach 35 kW, (more powerful are rare), and the capacity of the built-in boiler does not exceed 40 liters. Wall models - a great solution for small private houses with an area of about 100 m2 - 120 m2.

Although these devices have low power and small heating capabilities, they have their advantages:

- there is no need to allocate a special room for the wall-mounted boiler - just place the device in the bathroom or in the kitchen;

- most wall-mounted units are equipped with a closed combustion chamber, while the chimney can be removed through an opening in the wall.

Floor standing boilers are larger and heavier: the weight of such units can exceed 100 kg. Installation of such equipment implies the creation of a boiler room in compliance with the requirements of specialized SNiPs.

The rules regulate important parameters of the room equipment: ceiling height, podium dimensions for boiler equipment, air exchange rates. The combustion chamber of outdoor units is predominantly open type. This means that a steady supply of air is required for normal operation. However, floor standing boilers have more power than wall mounted boilers.

Wall-mounted units have a weak point - a heat exchanger. This part is often made of steel to reduce the cost of the boiler and reduce its weight. Condensate is formed on the walls of the heat exchanger having acidic properties, which leads to the destruction of the steel part. The cost of replacing the heat exchanger reaches 50% of the price of the boiler itself. Copper is more resistant to corrosion, therefore, copper heat exchangers have a long service life, however, the price of copper elements is higher.

In the manufacture of floor devices, there is no need to reduce the weight, so heat exchangers for such units are often made of cast iron. The main advantages of this material are heat capacity and durability. Cast iron service life reaches 50 years. However, such a heat exchanger has a disadvantage - fragility. In addition, sharp temperature changes in the supply and return pipes adversely affect cast iron.

When choosing between a floor-mounted and a wall-mounted gas boiler, it must be borne in mind that wall-mounted units are often cheaper because they are equipped with an expansion tank and a circulation pump. For outdoor equipment, these parts must be purchased separately, which leads to additional costs.

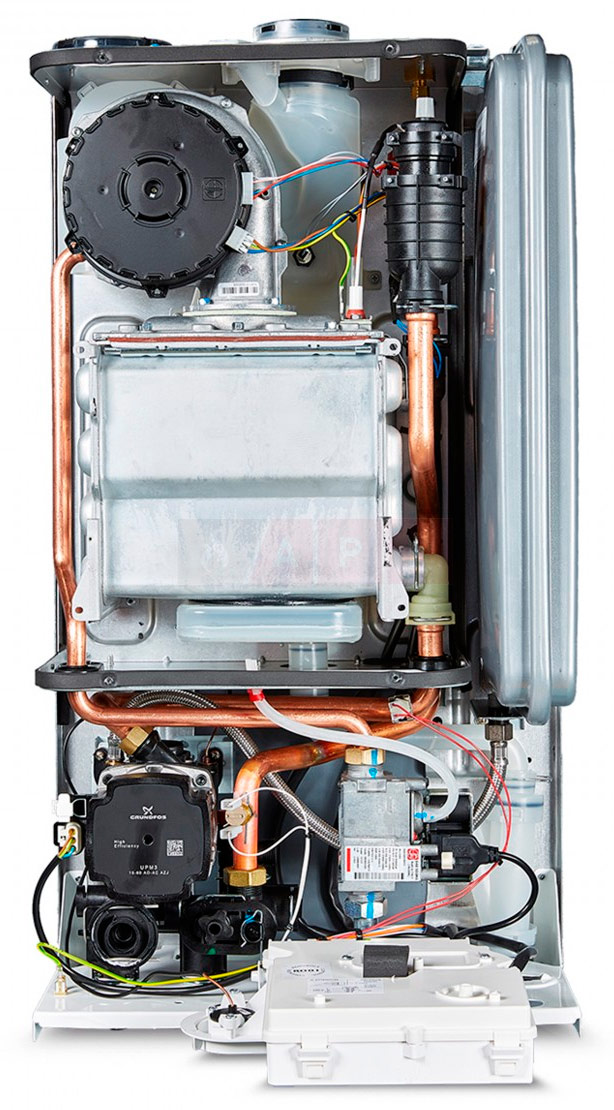

Wall mounted gas boiler equipped with tank and circulation pump.

In some cases, the heating system with a single-circuit boiler is filled not with water, but with a special antifreeze.This liquid does not lead to corrosion of metal parts and allows you to increase the life of the boiler and pipeline. Unlike water, antifreeze does not freeze at low temperatures, therefore, in winter, the heating system with antifreeze does not fail (and water can freeze and damage pipes).

Antifreeze can only be used in floor boilers. It is not suitable for wall models, as it can lead to deformation, leaks and environmental disasters of a local scale. This fact must be taken into account when choosing a gas boiler for periodic operation in the winter, for example, in country houses.

Single-circuit or double-circuit gas boiler

A single-circuit gas boiler is a single-line device that has one heat exchanger. Such boilers were originally intended for heating a country house and for installing a warm floor.

The double-circuit gas unit is equipped with two heat exchangers. The device is connected to two independent highways, one of which is intended for heating, and the second - for supplying hot water.

Heating water for hot water can be done in one of three ways:

- Heating with a boiler flow heater.

- Heating using a tank built into the boiler.

- Heating in a free-standing boiler.

It would seem that you can buy a double-circuit boiler for a house in which a large family lives, and for a house in which you only come for the weekend, a single-circuit one is enough. But in fact, such a solution will not always be optimal.

The main disadvantage of dual-circuit units with a flow-through water heating system is that heating and hot water supply cannot work simultaneously, but are switched on in turn. That is, while you take a shower, the batteries in the house cool down. At the same time, boilers with a capacity of up to 25 kW are not able to maintain a sufficiently high temperature at once for two points of water intake. That is, when one person takes a shower in the bathroom, and the other decides to wash the dishes in the kitchen, the shower will automatically become a contrast. Even the purchase of powerful models does not save the situation - because even with a connection diameter of ½ inch the water flow does not improve much.

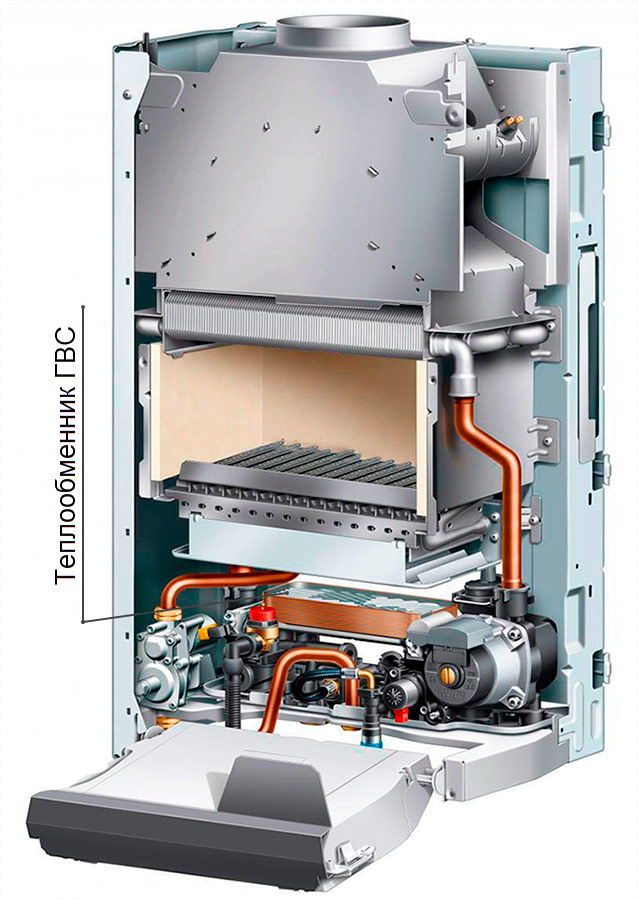

Double-circuit gas boiler.

If the tap is more than 5 meters away from the boiler, then after you turn on the water, you will need to wait 10-15 seconds for the cold water to change to hot. To solve this problem, you can get a dual-circuit gas unit with a built-in boiler, in which there is always hot water. The capacity of such a tank reaches 40 liters, sometimes more: this is enough for an express shower, but not for taking a bath.

Double-circuit gas boiler with integrated boiler.

In the case when hot water is required constantly and for the comfortable use of hot water supply, it is recommended to purchase a single-circuit unit and additional equipment - an indirect heating boiler. A free-standing boiler is used in cases where a large amount of hot water is needed - about 100-200 liters. This device is a capacious metal container with thermal insulation. Inside the boiler is a coil connected to the heating system of the house. Hot water or antifreeze moves along the coil, as a result of which the water in the tank heats up. If a small family lives in the house, then a boiler of 100 liters is enough. If the boiler is turned off, the water in the boiler does not cool down quickly.

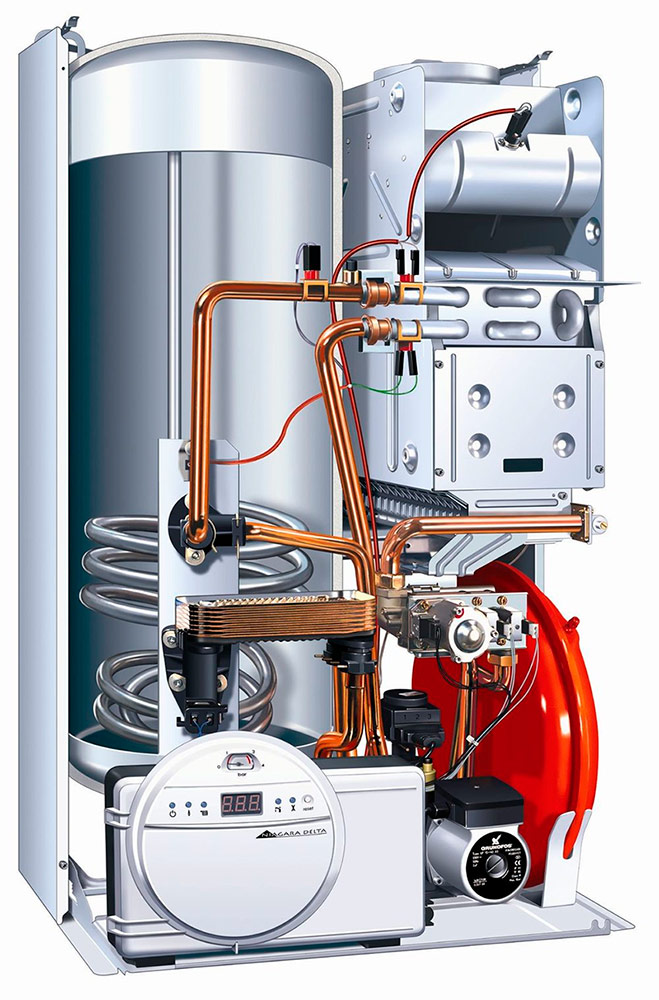

Single-circuit gas boiler with indirect heating boiler.

Photo: PROTON + company.

The disadvantages of such a system from a single-circuit boiler and indirect heating boiler include:

- higher cost of such a combination, compared with a dual-circuit unit;

- the need for a separate room as a boiler room.

At the same time, this combination of equipment allows for the recirculation of hot water: by opening any tap, you will immediately receive hot water.In addition to the system, you can connect a heated floor or heated towel rail, which will function when the heating is off. Recycling is convenient, but not always beneficial from an economic point of view.

If hard water is supplied through the pipeline, then buying a double-circuit boiler is not the best solution. This may result in the need to replace a secondary heat exchanger. The cost of such repairs can reach 50% of the price of the boiler itself. In fact, dual-circuit units are designed for small houses and apartments, since they take up less space and allow you to save free space.

Tip: sometimes a double-circuit gas boiler in combination with an electric boiler can be the best option. Thanks to such equipment, there will always be hot water in the house, even if one of the devices breaks down.

Convection or condensing gas boiler

Depending on the heating method, gas boilers are divided into two types:

- convection (or traditional);

- condensation.

This particular feature should be considered first of all when buying a boiler. However, before making the final choice of the desired type, you need to learn more about the features of this boiler equipment.

The principle of operation of the convection boiler: the fuel burns and heats the water, and the gases formed are removed through the chimney. The temperature of the gases exceeds 100 ° C, so they leave without having time to cool to the dew point and without leaving condensation on the pipe surface. The efficiency of a traditional boiler is about 90%.

In this case, partial losses of thermal energy occur when hot gases go into the chimney. For example, if the burner power is 20 kW, then only 18 kW is used to heat the coolant.

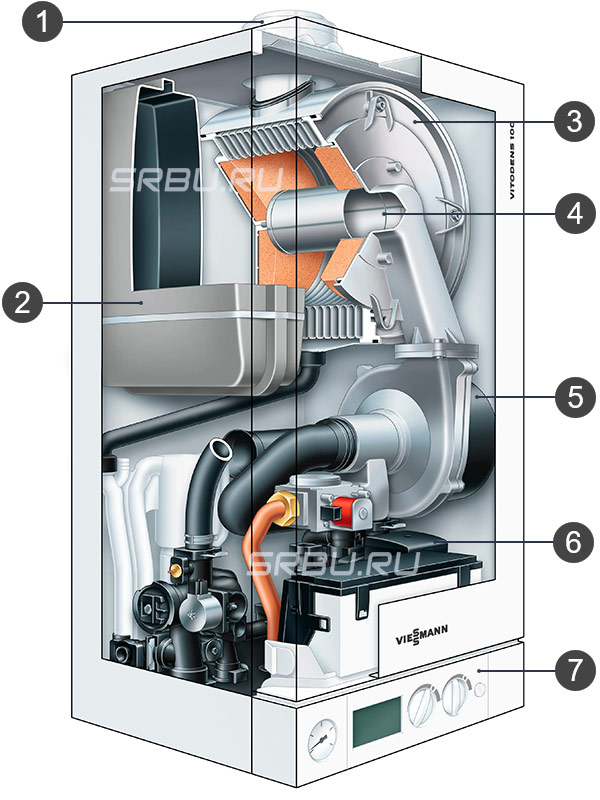

1. Chimney connection.

2. Supercharger.

3. Heat exchanger.

4. The combustion chamber.

5. Warmer.

6. DHW heat exchanger.

7. Priority valve.

8. Circulation pump.

To increase the efficiency in condensing boilers, exhaust gas heating is used. That is, the liquid goes through two stages of heating - exhaust gases, and then heating by gas combustion. As the flue gas cools, the proportion of energy used for its intended purpose increases.

Modern condensing type boiler units are more economical when certain conditions are met. Condensation is carried out inside the boiler, therefore, not only the energy from the combustion of the gas, but also the heat generated in the condensation process is most fully used. This is called higher calorific value. Thanks to condensation, it is possible to obtain a significant increase in heat, reaching 11%. In practice, the efficiency of condensing boilers is 106–109%. Here, the efficiency exceeds 100% due to the fact that the calculation of the efficiency of traditional boilers does not take into account the higher calorific value.

1. Chimney.

2. Expansion tank.

3. Heat transfer surfaces.

4. Modulated burner.

5. Burner fan.

6. Pump.

7. Control Panel.

It would seem that the massive replacement of boiler equipment with condensing units will lead to a massive effect. However, the situation is not so simple. When the gases cool to 57 ° C, condensation will begin. Water vapor present in the composition of the gases will gradually turn into a liquid state, accumulating chemically active substances. The condensate formed inside the boiler has high chemical activity, therefore, the heat exchanger must be made of the appropriate material. Part of the aggressive condensate enters the chimney, so it must also be resistant to such an effect. The resulting liquid must be removed from the system, for example, into the sewer (if the regulatory authorities allow condensate to be drained there).

However, this is not always possible: often boilers are placed in basements that are not equipped with a sewage system. When using a septic tank, condensate can not be drained into the sewer, as this will lead to disruption of its operation.Therefore, additional equipment may be needed - equipment that performs chemical neutralization of the condensate, as well as consumables for it.

As a result, the cost of the condensing boiler is much higher, a regular chimney is not suitable for it, and it is necessary to solve the problem of condensate utilization. If the increase in thermal power reaches 10-15%, then it will be beneficial. However, such an increase is possible only in the best case.

To cool flue gases, it is necessary to take thermal energy from them and transfer it to the water entering the boiler. In this case, it is necessary to consider what type of heating system is used: low-temperature or high-temperature heating system. Low-temperature heating systems include water heated floors.

If a water heated floor is installed in the house, then water with a temperature of about 30 ° C enters the boiler. Condensation occurs at temperatures around 55 ° C. Therefore, in such a situation, it is possible to effectively cool the flue gases so that condensation is carried out in the boiler.

Water floor heating.

But in cases where radiators are used to heat rooms, the temperature of the coolant at the inlet to the boiler remains high - an average of about 50 ° C. With such indicators, it is not possible to sufficiently cool the gases. As a result, only partial condensation occurs in the boiler, and a significant proportion of the combustion products are cooled already in the chimney.

Thus, condensation-type boiler equipment can only work effectively in cases where there is a low-temperature circuit in the heating system. In systems with radiator heating, the efficiency will be slightly higher than that of a traditional boiler, but will not reach the maximum possible value. In practice, at a temperature difference of water from 80 to 50 ° C, the efficiency is on average 95–98%.

When calculating the power of condensing equipment, it is necessary to clarify the required heat capacity and take into account the efficiency in these conditions. The documentation usually indicates at least two values of the efficiency: for a difference of 80–50 ° C and for 50–30 ° C. Therefore, you need to choose a boiler based on the type of heating system.

Which gas boiler is better and whether it is worth installing a condensation model - you need to decide in each individual case. For example, if in a high-temperature heating system it is easy to replace the boiler with an expensive condensing one, the increase will not be significant. With new construction and installation of a warm floor, you can get about 15 additional percent of power.

The best wall mounted gas boilers

Bosch Gaz 7000 W MFA

The lineup.

In this line of the German brand there are five models operating on the main and liquefied gas. These are wall devices with a closed combustion chamber, the power of boilers is 24, 28 and 33 kW. Cost-effective devices are effective for heating and hot water. Additional advantages of these units are ease of installation and compactness.

Hot water preparation.

The lineup includes dual-circuit models equipped with two heat exchangers for hot water supply, and single-circuit ones that require additional installation of a boiler.

Design features.

- Stainless steel atmospheric burner with the ability to work on liquefied gas.

- Primary monothermal heat exchanger.

- The presence of a three-way mixing valve with an electric actuator for connecting a boiler.

- Electronic type ignition.

- Two-mode preparation of hot water: Comfort for constant high temperature and Eco for heating water if necessary.

- Protection against boiler pump from blocking, freezing, scale.

- The system of eliminating thermal inertia.

- Protection of the boiler against legionella.

Equipment.

The equipment provides the ability to modulate power in DHW and heating modes. There is a Bosch Heatronic 3 control module, a security system is built into the control board. Units are equipped with a self-diagnosis system with wide functionality.

Additional Information.

The efficiency of boilers is 91%. The devices are equipped with a wide range of remote controllers, thermostats, weather-dependent programmers and timers. Due to compatibility with solar systems, it is possible to change the settings of the heating and water supply systems taking into account the intensity of exposure to the sun.

Baxi eco four

The lineup.

The Italian wall-mounted boilers presented in this model range operate on liquefied or main gas and have a capacity of 14 and 24 kW. The lineup includes three models of heating equipment designed for country houses, cottages and offices. These devices are in great demand in the Russian market because of their performance, compact size and many other qualities.

Hot water preparation.

Dual-circuit models allow heating water in flowing mode, and when installing a single-circuit boiler to provide hot water supply, an indirect heating boiler must be connected.

Design features.

- Primary copper heat exchanger.

- Stainless steel burner and heat exchanger for domestic hot water.

- Protection against blocking and freezing.

- The circulation pump is equipped with an automatic air vent.

- The smallest permissible gas pressure is 5 mbar.

- Automatic bypass.

- Smooth electronic ignition and electronic flame modulation.

- Heated water flow sensor.

Equipment.

A programmable timer and thermostat can be connected to the device. To display information about the functioning of the system, a liquid crystal screen is used. Boilers of this model range are equipped with an electronic self-diagnosis system with the ability to display a blocking signal on the control panel.

Additional Information.

You can connect a street temperature sensor to the devices, since weather-dependent automation is built into them. The temperature in the heating circuit is regulated and maintained in automatic mode.

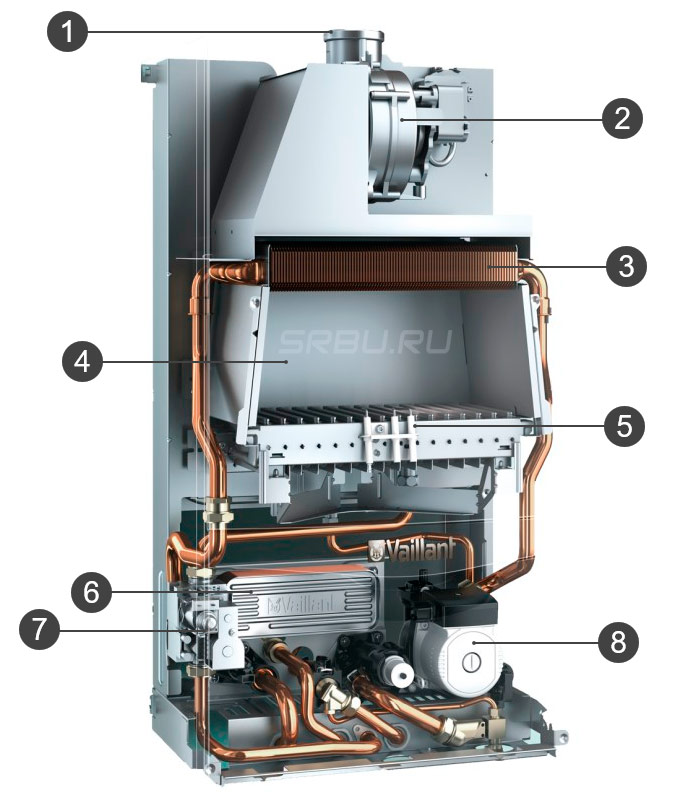

Vaillant turboTEC plus VU INT

The lineup.

In this model line of the brand Vaillant (Germany) 6 boiler models are presented. All models can use main or liquefied gas as fuel. The power of wall units varies from 12 to 36 kW. All models of this line are single-circuit, equipped with a closed combustion chamber.

Hot water preparation.

All boiler models are single-circuit and are intended only for the heating system. To prepare hot water, an indirect heating boiler is required. It is possible to combine with a variety of VIH water heaters.

Design features.

- Copper primary heat exchanger.

- For the manufacture of the burner, chromium-nickel steel is used.

- The circulation pump is equipped with an automatic step switch.

- Frost protection system and constant pressure control in the heating system.

- Expansion tank closed.

- Automatic air vent.

- Electronic ignition.

- The equipment has a built-in switching module for the e-bus interface.

Equipment.

The boilers are equipped with automatic bypass and safety valves. There is a priority switching valve with an electric actuator. The devices provide protection against jamming of the pump and the three-way valve resulting from downtime. A backlit liquid crystal display allows you to monitor the status, and a diagnostic system helps to quickly detect malfunctions.

Additional Information.

The coefficient of performance exceeds 91%. In heating mode, it is possible to tune to partial power. It is permissible to assemble a cascade design based on boilers of this line.

Protherm Panther KTV

The lineup.

This model range of a brand from Slovakia includes two models of wall-mounted double-circuit gas boilers with a closed combustion chamber. Units with a capacity of 24 and 29 kW are able to operate on main or liquefied gas. A distinctive feature of this line is increased comfort in use and maintenance.

Hot water preparation.

Hot water is produced in a plate heat exchanger made of steel or in a separate storage boiler. Water is heated at a rate of 14 liters per minute.

Design features.

- Hot water plate heat exchanger made of steel.

- Closed combustion chamber.

- Efficiency 91–92.8%.

- Flame modulation in automatic mode.

- Independent adjustment of thermal loads of the heating system and domestic hot water.

- Microprocessor control.

- Built-in circulation pump equipped with an automatic air vent.

- Integrated feed valve for filling the heating system with fluid.

Equipment.

Diagnostics of equipment operation is performed automatically. There are two control modes: “Comfort” and “Winter - Summer”. The boiler is protected from overheating and freezing, there is a built-in control of the presence of flame and draft in the chimney, as well as a pump anti-lock system. Devices of this model range are able to work with weather-dependent automation. The parameters of the heating system, information about malfunctions and the need for maintenance are displayed on the LCD.

Additional Information.

Boiler equipment is able to work fully automatically throughout the year. In the process, the temperature indicators of water are controlled not only at the inlet of the heating system, but also in the return line. Thanks to this, the most accurate adjustment of the power of the unit is achieved. With the help of an intelligent control system, it is possible to reduce the number of on and off equipment and extend its service life.

The best floor gas boilers

Vaillant atmoVIT VK INT

The lineup.

In this brand line from Germany, there are six floor-mounted gas boilers, the power range of units is from 16 to 56 kW. The devices are equipped with an atmospheric injection burner without a fan. These boilers can be used as heat generators for heating and hot water supply. Natural gas is used as fuel, but when reconfiguring equipment, it is possible to use liquefied gas.

Hot water preparation.

One of the models is capable of producing instantaneous water heating; in the rest, indirect water heater is required for the preparation of hot water.

Design features.

- Cast iron sectional heat exchanger.

- Atmospheric injection type burner.

- High efficiency indicators, reaching 92%.

- Low emissions.

- Electronic ignition and integrated flame monitoring system.

Equipment.

The devices are equipped with built-in temperature and traction sensors. The burner has ceramic rods for heat dissipation, as well as an automatic pressure regulator. It is permissible to connect various analog type controllers. The equipment has a safety temperature limiter. An additional convenience is the ability to adjust the height of the boiler legs.

Additional Information.

Thanks to the cast-iron heat exchanger, the durability of such boilers is high. Therefore, the equipment will serve for a long time and please the owners.

Viessmann Vitogas 100-F 29-60

The lineup.

This line includes 15 boiler models with power ranging from 29 to 60 kW. The equipment combines economical fuel consumption with high efficiency (92%). When choosing which gas boilers are the most economical and practical for the home, you should pay attention to the units from this model range. The devices have high operational reliability even with significant fluctuations in pressure in the gas pipeline and voltage in the mains.

Hot water preparation.

To provide hot water, you need to combine the device with a capacitive storage.

Design features.

- Stainless steel rod burner.

- Durable gray cast iron heat exchanger.

- Full automation of the work process.

- Silent ignition and high ignition reliability.

Equipment.

Units are equipped with a gas pressure monitoring switch, which is necessary in cases of low pressure. Digital programmed control of the boiler operation is provided.

Additional Information.

The devices have good fuel economy and compact size. The boilers in this series are environmentally friendly and meet the requirements of the Blue Angel.

Protherm Bear KLOM17

The lineup.

Slovak floor boilers of this line are represented by four models. The power of the devices is 17–44 kW, and the main or liquefied gas is consumed as fuel. Gas equipment is designed for heating private homes and small commercial facilities.

Hot water preparation.

Boilers are designed for heating, but heating water for hot water is possible in an external boiler.

Design features.

- The coefficient of performance reaches 90–92%.

- The two-way heat exchanger is made of cast iron with condensation protection, has from 4 to 8 sections.

- Open type combustion chamber.

- Stainless steel atmospheric burner.

- Electric ignition.

- Infinitely variable power.

- Built-in traction and flame control system.

- Overheat protection and cooling circuit.

Equipment.

The boilers are equipped with built-in microprocessors that allow you to effectively manage equipment in the "Winter - Summer" mode. Indication of indicators of pressure and temperature, work with weather-dependent devices.

Additional Information

The equipment is stable during operation in all hydraulic modes, it is supplied fully assembled. The boilers are easy to install and maintain. The middle sections of the cast-iron heat exchanger can be replaced.

Baxi slim

The lineup.

The line of floor boilers Baxi (Italy) is represented by 10 models with a capacity of 22–62 kW. Units work on the liquefied and main gas. Devices of this wide range are equipped with a cast-iron heat exchanger.

Hot water preparation.

Bypass models have a built-in boiler for hot water. It is possible to connect an external storage boiler.

Design features.

- Self-diagnosis system.

- Durable cast iron heat exchanger.

- Electronic flame modulation.

- Efficiency reaches 90.5%.

- Two ranges of temperature control (for operation in radiator heating and underfloor heating).

Equipment.

The boilers have built-in frost protection, overheating and blocking systems, flame control. The equipment is equipped with high-speed circulation and post-circulation pumps, built-in weather-dependent automation, traction sensor, pressure gauge and safety valves.

Additional Information.

Boilers are compact in size and modern in design. Regulation and automatic maintenance of the set temperature in the heating circuit and in the boiler are provided. You can optionally connect a programmable timer.

Bosch Gaz 2500 F

The lineup.

The model range is represented by five boilers, the power of the units is 22, 26, 33, 42, 50 kW. The main gas is used as fuel. The boiler equipment is designed to provide heat and hot water at home with an area of up to 500 m2.

Hot water preparation.

Units are able to work with free-standing indirect heating boilers.

Design features.

- The heat exchanger is made of steel 3 mm thick.

- It is possible to adjust the power depending on the load in the range from 60 to 100%.

- Highly efficient boilers with an efficiency of 92%.

- Large diameter connection of the boiler unit to the heating system.

Equipment.

The boilers of this line are equipped with a modern control system, disinfection function and frost protection.

Additional Information.

To increase the comfort of operation, it is permissible to connect regulators. The devices are easy to install and operate, fully adapted to Russian conditions of use. During operation, the DHW priority is provided over heating. In the "Summer" mode, the device operates only to ensure hot water supply.

The best condensing gas boilers

De Dietrich Innovens PRO MCA

The lineup.

Condensing boilers of the French brand have a capacity of 43 to 114 kW and a closed combustion chamber. There are eight models in total in this line. The devices have a wall mount, have a stylish modern design and small size. They are great for bathroom or kitchen. Due to improved indicators of energy saving, increased productivity and safety, these units occupy high positions in the rating of gas boilers for reliability and quality.

Hot water preparation.

Boilers of this model range provide comfortable heating and hot water in the required volume.

Design features.

- The coefficient of performance reaches 102.5%.

- Monoblock heat exchanger made of aluminum and silicon alloy.

- Steel burner with silencer.

- The shell insulating body is made of composite materials.

- Automatic electric ignition.

- Built-in sensors for flame monitoring.

- Reduced noise due to the use of a centrifugal fan.

- Condensate trap.

- Automatic air vent.

- Indoor LED backlight for easy maintenance.

- Flue gas temperature sensor.

- Control and self-diagnosis systems.

Equipment.

There are two control panels to choose from: basic IniControl and weather-dependent Diematic iSystem. The installation of an additional street temperature sensor allows you to modulate the power of the burner taking into account external temperature indicators. All parameters of the system and the status of the boiler are displayed on the LCD.

Additional Information.

Devices of this model range possess not only high efficiency, but also low noise level, as well as low rates of harmful emissions.

Viessmann Vitodens 100-W

The lineup.

The range includes five wall condensing units operating on main and liquefied gas. The power of the boilers is 19–35 kW. They are suitable for creating a heating system in private homes and commercial buildings. The models in this line represent the optimal combination of performance, reliability and competitive price.

Hot water preparation.

Thanks to the double-circuit plate heat exchanger and the temperature controller, comfortable preparation of hot water is possible. For single-circuit units, the installation of an indirect heating boiler is required.

Design features.

- The efficiency is 108%.

- Low content of harmful substances in flue gases.

- By adjusting the fan speed, good economy is achieved.

- Stainless steel heat exchanger with increased corrosion resistance.

- Steel burner cylindrical.

- The economical modulation principle of combustion.

- Electronic control system.

Equipment.

The boiler is equipped with protection systems against blocking, overheating and freezing. The operation of the device is regulated by wired and wireless regulators - digital and analog room thermostats. The unit is equipped with an integrated expansion tank, a variable speed fan, and a digital control device.

Additional Information.

When servicing equipment, additional space is not required, since all elements are accessible from the front side.

Vailliant ecoTEC plus VU OE

The lineup.

This series includes only two models of single-circuit boilers. These condensation boilers Vaillant (Germany) have a capacity of 45 and 65 kW. The advantages of units include cost-effectiveness and environmental friendliness. Boilers are used in low-temperature heating systems; they are well suited for mounting a boiler room on the roof.

Hot water preparation.

For the preparation of hot water, the installation of a DHW cylinder is required.

Design features.

- The average value of the efficiency during the heating season is 109%.

- Wide range of modulating burner power (28–100%).

- Automatic air vent.

- Two-stage pump with automatic switch.

- Adjustable fan speed.

- Expansion tank.

- Built-in siphon for condensate drainage.

- Safety valve.

Equipment.

To effectively use the thermal energy of condensation, the Aqua-Kondens system is used. The boilers have an electronic type ignition and a combustion control system. An e-bus interface has a built-in switching module.

Additional Information.

To maintain combustion, you can use air from the room or from the outside. It is possible to adjust and install partial power for domestic hot water and heating.

Baxi duo-tec compact

The lineup.

Three boilers of this line of the famous Italian brand combine advanced technology, ease of installation and use. The power of these wall units is 24–28 kW. Devices are able to adapt to the type and quality of fuel, chimney parameters and other factors. The equipment is intended for heating industrial and domestic premises in country houses and cottages.

Hot water preparation.

Providing hot water in dual-circuit models is carried out in flow mode. When installing a single-circuit boiler, installation of an indirect heating boiler will be required.

Design Features

- Primary stainless steel heat exchanger.

- Stainless steel burner.

- The two-speed circulation pump with increased energy efficiency is electronically controlled.

- Built-in air vent operating in automatic mode.

- Three-way solenoid valve.

- Automatic bypass.

- Filter for incoming cold water.

- The hydraulic group is made of composite.

- Ionization flame control system.

Equipment.

The boiler equipment is equipped with two temperature sensors: on the feed and on the return line. The weather-dependent automatic system has a self-adaptation function. The system can control the temperature in a wide range: from 25 to 80 ° C. The set heating temperature is maintained automatically.

Additional Information.

When reconfiguring the system, liquefied gas can be used as fuel. When the pressure drops below 0.5 bar, the burner shut-off function is activated. The boiler equipment provides a system of independent diagnostics, protection against overheating, blocking and freezing. The safety of removed products is monitored by an NTC sensor.