Liquid wallpaper application technology - how to do it right

Modern technologies for finishing walls allow you to use many decorative materials. An alternative to the classic type of wallpaper is a wide range of coatings called liquid wallpapers. Liquid wallpaper, the application technology of which is discussed in this article, has a large color gamut and a variety of textures. This allows you to realize any of the boldest design decisions.

The advantages of decorating with liquid wallpaper

In addition to its impeccable appearance, the rationality of the use of liquid wallpaper is associated with a high degree of wear resistance. They are practically not subject to mechanical damage, flooding and other accidental negative influences. Their surface lends itself to washing and cleaning. From them you can even remove the wall painting of little playful little girls. This allows you to save a fairly long period of pristine beauty of the repair. In most cases, they can last more than 10 years.

The advantage of this type of wallpaper is noticeable even at the initial stages of repair work. Their use makes it possible to advantageously hide cracks, bumps and other wall defects. This saves a significant amount and time for performing puttying work. The technology for applying liquid wallpaper is not demanding on possessing special skills and knowledge, which cannot be said about painstaking pasting with classic wallpaper.

With the manifestation of various defects, when applying liquid wallpaper, or damage during operation, the damaged place is easily brought into proper form. To do this, you need to moisten this area well by carefully removing a layer fragment. Then it is steeped and returned to its original place. After complete drying, there will be no trace of the restoration work. The transformed wall will look great again.

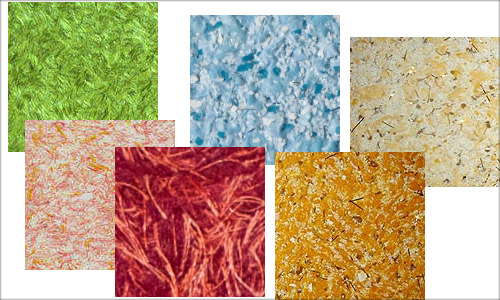

Different patterns of jellied wallpaper.

Wall surface preparation

From competently carried out work on the preparation of the wall surface, the quality of the applied coating depends. These works consist of removing the remnants of the previous finish: old wallpaper, a layer of whitewashing, etc. As a result, a homogeneous dry concrete surface should be obtained.

All metal elements found on the wall must be removed. If it is impossible to achieve such an effect and either the complexity of the process, it is possible to paint over such places with oil paint. The ingress of moisture on them will contribute to the development of a corrosion process, the manifestation of which will be reflected in the form of rust spots on new wallpapers.

For a high-quality result of applying liquid wallpaper, it is necessary to primer the wall with acrylic primer or paint it with water-based paint. It must be remembered that the surface of the wall should be whitish, this is necessary in order to get exactly the shade of wallpaper that was conceived.

Primer the walls with acrylic primer using a roller.

Preparation of a mixture of liquid wallpaper

As a rule, liquid wallpapers are packaged in bags and visually resemble sawdust. Their composition already contains all the necessary components to create a high-quality decorative coating. For their preparation, it is necessary to dilute their dry composition with warm water (up to 40 0C) to obtain a homogeneous mixture, medium density (sour cream). As a standard, 1 pack of dry wallpaper mix requires 6 liters of water. It is necessary to perform their mixing manually, because the use of various mixers will lead to crumbling of elements and a change in the planned structure of the wallpaper.

The resulting solution must be infused for at least 12 hours before application.Before direct distribution on the surface of the wall, it must be thoroughly mixed again.

Drawing liquid wall-paper on a wall

The process of applying liquid wallpaper is done with a spatula. The applied layer elements are evenly distributed over the surface area with a special roller or grater. Some types of liquid wallpaper can be applied using a Hopera pistol.

Surface coating should be done from the corner or some edge of the wall. Regardless of the thickness of the applied layer, the decorative characteristics of the wallpaper remain unchanged. For the optimal amount of consumable material and the drying period, the recommended thickness of the finish layer is not more than 2 mm. At the same time, it should remain unchanged over the entire area of the walls of the room.

An important point when applying liquid wallpaper is the regulation of the force of pressing the spatula or grater. Its excessive pressing against the wall will result in pressing of the elements and distortion of the textured layer. And its insufficient pressing will cause the uneven distribution of the thick layer.

When working with a spatula or grater, only reciprocating movements must be performed, not circular. The entire surface of the wall should be a layer of one batch. If there is doubt about the lack of the right amount of mixture, it is better to prepare a new one in sufficient quantity.

The remnants of diluted mixtures of liquid wallpaper can be dried and left in reserve. If necessary, they can be reused without loss of quality.

Depending on the individual composition and thickness of the layer of applying liquid wallpaper, as well as certain conditions of temperature and humidity of the room, the required drying time is 12-72 hours. In addition, it is affected by the method and technology of application.

Video. Master class on applying liquid wallpaper