Long burning stove for giving: types, how to choose, the best manufacturers

The arrangement of a country house with a heating system is the most important task that should be solved even at the stage of construction or major repairs of the building. Sometimes for these purposes it is convenient to use long-burning wood-burning stoves for cottages. Modern models can not only effectively maintain heat in your home, but also help in cooking, as they are equipped with a hob or oven.

The selection of goods was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.

Disadvantages of Natural Burning Fireplaces

Traditional open hearth fireplaces ceased to meet modern consumer requirements. They create an atmosphere of warmth and coziness in the room, but they are inferior in efficiency even to a Russian stove or a Dutch woman. The inability to control the air flow necessary for the combustion of solid fuels is the main reason for their low efficiency. In classic models, it rarely exceeds 20%.

The main disadvantages of conventional fireplace stoves:

- solid fuel often does not burn completely, leaving a large amount of a mixture of ash and coal on the grate;

- unregulated strong draft leads to intensive intake of external cold air into the room, for the heating of which additional energy needs to be spent;

- unburned soot particles, harmful carbon monoxide (carbon monoxide), and other gaseous products of thermal decomposition of organic substances fly out of the chimney.

The operation of a traditional fireplace is not only economically unprofitable, but also adversely affects the environmental background around the building. It is no coincidence that throughout the world there has been an increase in the popularity of long burning stoves, which are devoid of the above disadvantages.

Advantages of long burning stoves

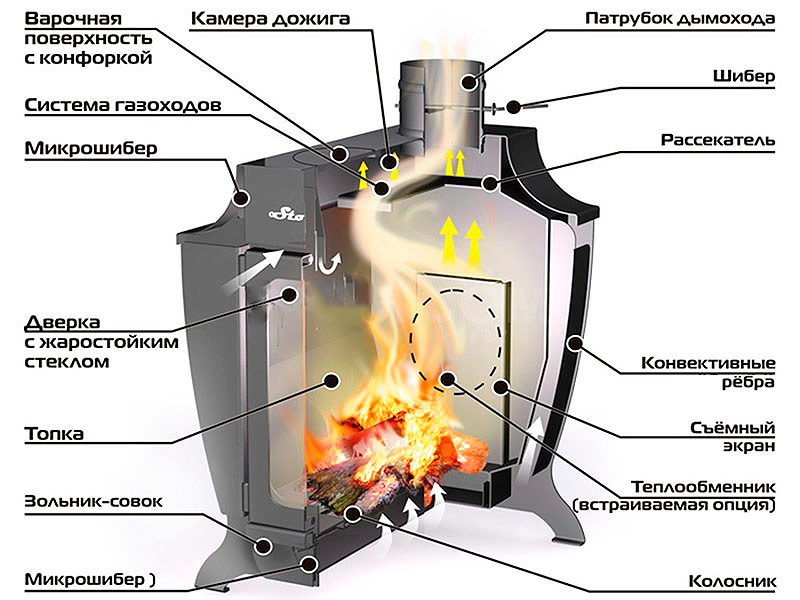

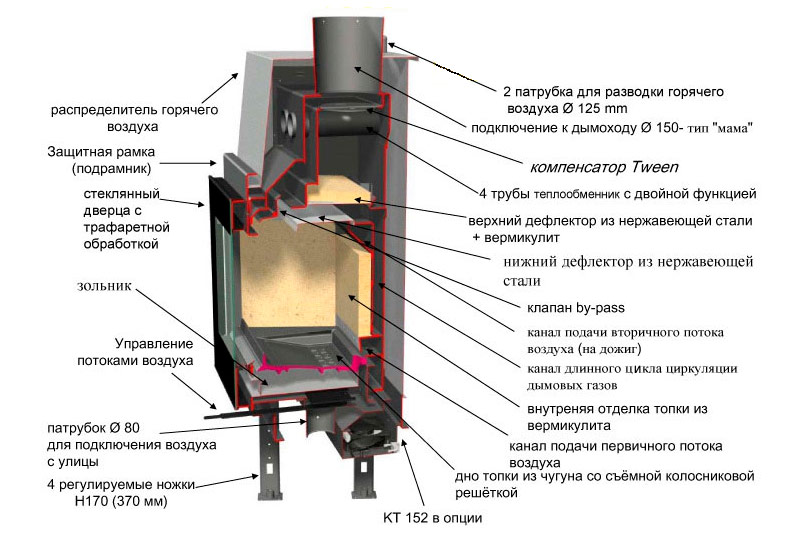

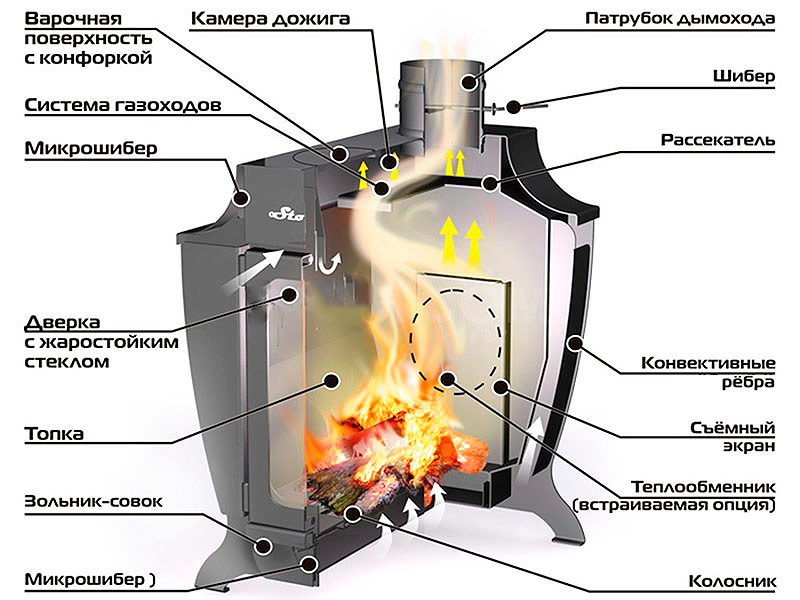

The main feature of a modern fireplace stove is the regulated process of burning solid fuel, which occurs in the main chamber with some oxygen deficiency. Firewood in this mode does not flash with a bright flame, but smolders for a long time. At the same time, a temperature sufficient for pyrolysis is maintained - decomposition of high molecular weight compounds to simple gases, including CO. They completely burn out at the exit of the furnace, where additional air enters in the required quantities. As a result, the maximum amount of heat is generated and no harmful emissions occur.

Unlike a pyrolysis boiler, a fireplace stove does not need additional energy sources. She does not need a forced air supply, which in this case comes from natural draft in two streams:

- primary air is supplied to the lower part of the main combustion chamber;

- secondary air is mixed with the exhaust gases at the outlet of the furnace.

The best fireplace stoves arranged in this way demonstrate an efficiency of 75-85%.They require a small bookmark of firewood and do not need to be added for a long time, providing long-term heating of the room. The main process of heat transfer in them occurs due to thermal radiation, but there are convection fireplaces that supply heated air through pipelines to neighboring rooms. At the same time, all such devices retain the main advantage of an ordinary fireplace - the ability to admire the playing flames.

How to choose a long burning fireplace stove

For the right choice of a fireplace stove for heating a country house, it is desirable to have a clear idea of its structure and principle of operation. This will save purchase costs and avoid errors during operation.

Design Features

The gas-dynamic processes taking place in the furnace of a fireplace with a high level of efficiency depend on many parameters. It is hardly possible to independently achieve the optimal design based on clay and fireclay bricks. It is better to give preference to factory developments that have passed the design stage and repeated tests in a variety of operating modes. They are a ready-made technical device that you just need to correctly install in place and operate in accordance with the manufacturer's recommendations.

For the installation of a fireplace stove, it is not necessary to specially prepare the foundation or a niche of brick or stone. The device is mounted in compliance with fire safety regulations to an empty place and pipes are connected to it for the removal of flue gases.

The fireplace itself is a sturdy case with the necessary devices installed inside it. Doors are usually made of heat resistant glass. It is blown with secondary air directed into the exhaust gas afterburner, which prevents soot from settling.

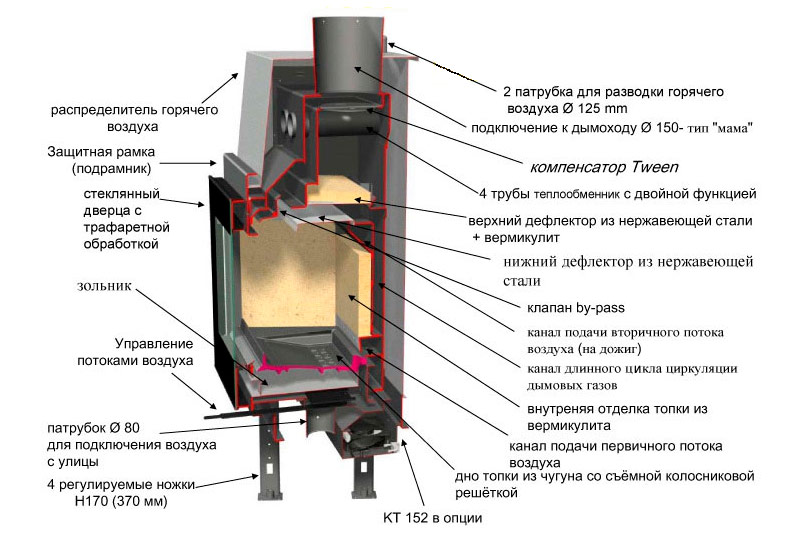

The device and scheme of operation of a long-burning furnace

Applicable Materials

In the manufacture of the main elements of fireplace stoves, cast iron is often used. It easily tolerates numerous heating and cooling cycles. Such material is almost not subject to corrosion. He needs a little more time to warm up, but he keeps the heat longer.

Cast iron fireplace stove.

Heat-resistant steel grades are considered a worthy alternative to cast iron. Some manufacturers are actively using stainless steel. Steel products weigh less and are easier to manufacture.

Steel fireplace stove.

With prolonged contact with an open fire, it is likely that they will lose their strength characteristics and burnout, therefore, cases of high-quality fireplaces made of steel are usually protected from the inside by a lining.

To do this, apply:

- fireclay tiles or bricks;

- refractory clay mixtures;

- special compositions based on chamotte clay in combination with aluminum and titanium;

- vermiculite protective materials;

- cast iron inserts.

The device of the fireplace stove with lining of vermiculite.

For the outdoor decoration of metal fireplaces, they often use:

- ceramic tile;

- decorative rock;

- iron casting;

- heat-resistant enamels.

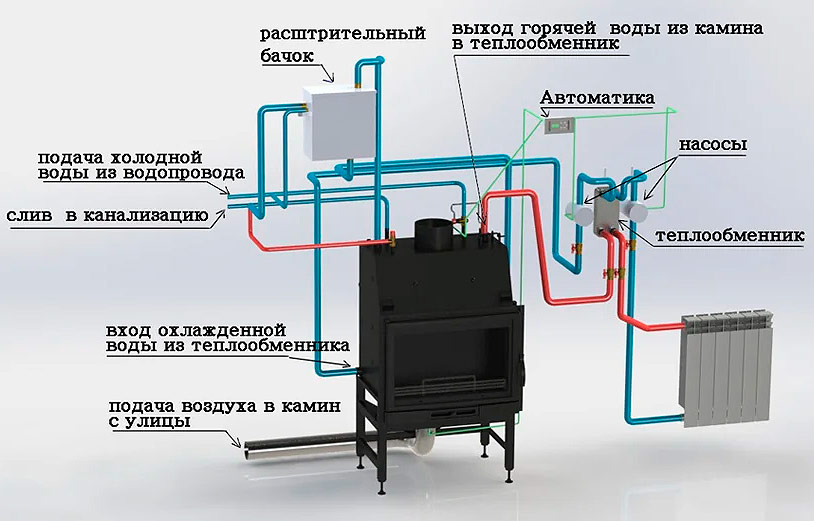

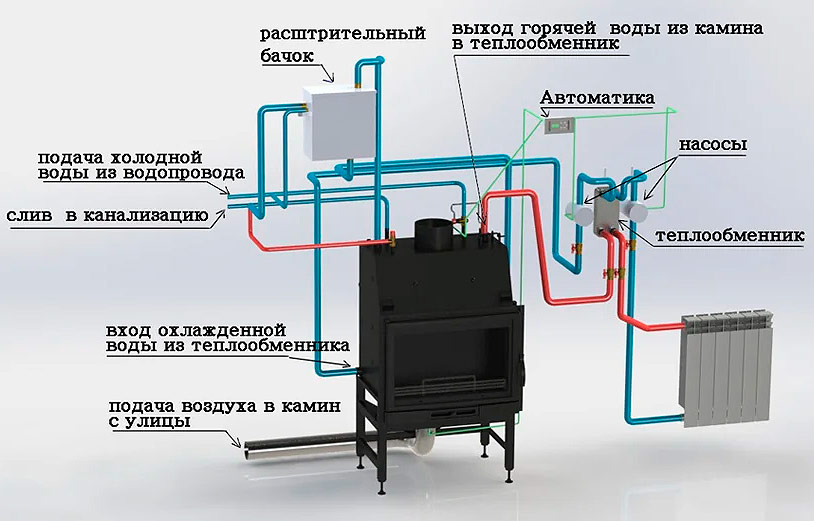

In which case it is advisable to use a fireplace stove with a water jacket

In the absence of alternative sources of heating for a large house, a conventional fireplace stove will not be able to maintain a normal temperature in all rooms. Thermal radiation is not able to penetrate walls and partitions. In such a situation, it is better to purchase a model with a water or air jacket. On their basis, it is possible to create a heating system for each room by adjusting the circulation scheme of the liquid coolant or by organizing the supply of convective air flows through special air ducts.

The device of the heating system of the fireplace stove with a water circuit.

How not to make a mistake with the power of the chosen model

The general rule for calculating the required amount of heat for heating a well-insulated building is also applicable for long-burning stoves. In general, for every 10 m2 The area of heated rooms requires 1 kW of thermal energy.

Most fireplaces without a water circuit develop power from 4 to 12 kW.This is enough to heat a small country house or cottage with a total area of up to 150 sq.m.

Fireplaces stoves with a water jacket often reach a power of 25 kW. The manufacturer usually indicates how much of it is released as thermal radiation and how much energy is given to water. These data should be taken into account when choosing a room for installing a fireplace and designing a coolant circulation scheme.

If you have mastered the theoretical part of the information presented here without any problems, then you can consider yourself ready to choose a specific model.