Doors with which finishes are better: veneered, laminated or with PVC film

To determine which doors are better: veneered, laminated or PVC, we will compare these finishing materials for a number of parameters. Each coating has its positive and negative sides. Even the most expensive coating is not without flaws. In addition, in the kitchen, in the bathroom or living room, the requirements for the doors are somewhat different. Also an important factor will be the budget that you can count on when planning such a purchase. The choice for comparison of these door trim materials is due to their greatest popularity among consumers.

Content:

What is each type of door trim

The main task that stands in any production is to reduce the cost of production while maintaining quality. Since the manufacture of doors often uses materials other than the original ones (if earlier they were made of solid wood, now it is more likely to be considered a luxury), the standards themselves have changed. It is clear that there can be no unique solution, for example, which is better - PVC doors or veneer, each coating has its own characteristics. To get started, consider each material and its constituent elements.

Veneered doors

Externally, doors made of this material are closest to classical solid structures - these models have the same surface pattern, similar operational properties, but their cost is much lower. This is due to structural features, because the veneer is a thin cut of wood, with a thickness of 0.2 to 5 mm and it is glued to the outside of the door surface.

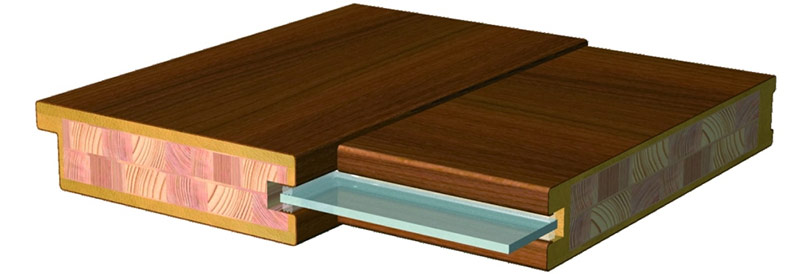

The inner part is made either from a solid mass of less expensive wood, or from particleboard and MDF. Another option is a frame made of pine bars, the cavities in which are filled with cardboard honeycomb and sheathed with MDF sheets. This design has a much lower weight than the models from the array, but it has a slightly lower strength.

The veneer layer is glued to the finished frame by vacuum hot pressing, which ensures the strength and durability of the fastening. For maximum safety of appearance, the finished doors are varnished - this emphasizes the wood pattern, protects the veneer layer from ultraviolet radiation and mechanical stresses.

As a result, veneered doors do not outwardly differ from those made of solid wood - they may be given to lay people by the lesser weight of the structure, but for interior models this is more of an advantage. Since such doors are made of different artificial materials, they are less sensitive to temperature extremes, and the low cost compared to solid models makes this option one of the best buying solutions.

A common drawback of such door leafs is inherent in all wooden models - it is better not to install them in wet rooms without special treatment. It is also better not to put veneered doors in the place where direct sunlight falls - despite the protective varnish, they may darken over time.

Laminated Doors

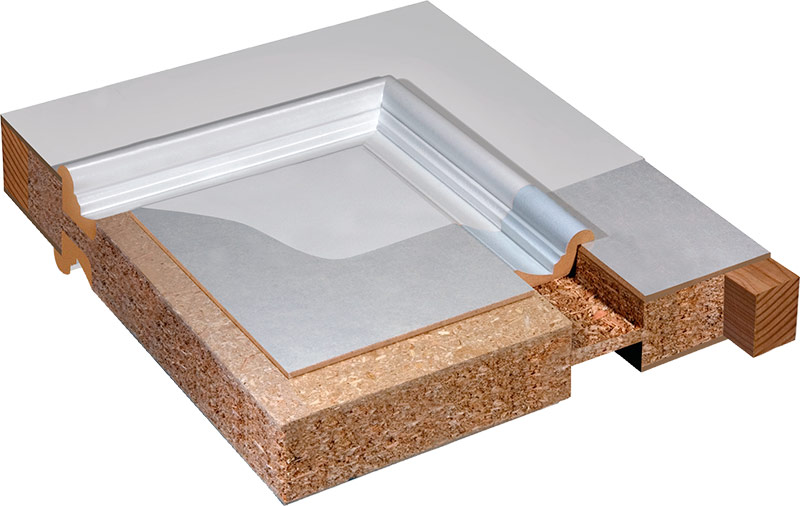

This is one of the most economical options. Structurally, they are a wooden frame, lined with MDF panels, on which a laminated coating is applied with the desired pattern or color. Outside, the surface is covered with a protective layer. The internal cavity of the frame is filled with various fillers - mainly cardboard honeycombs, but chipboard and MDF can also be used.

The main advantage of such a door is its low cost and stable coloring - the technology of manufacturing a laminate allows you to get the same color even in products from different parties.

The laminate is resistant to moisture, and the frame of the door ensures that there is no deformation from temperature extremes. Such models are characterized by reduced weight, so they can be used for installation in any interior partitions.

Eco-veneered doors

Eco-veneer is a polyurethane foam film with wood shavings. Ecophone found application in door production for a number of reasons. In particular, natural wood fibers glued together by polymers are used in its manufacture. When applied to a flat surface, its relief becomes like a tree, and not only externally, but also to the touch.

An eco-friendly eco-veneer is called for the reason that it is chemically inert and does not contain chlorides in its composition - this is one of the criteria that can be followed when deciding which is better - PVC doors or eco-veneer. In any case, there is nothing in common between eco and natural veneer, except for the surface texture. Some sellers use external resemblance and present ecophone as “the same veneer, only better”, arguing that they are not afraid of moisture. In fact, only the internal parts of the frame are identical here, and the outer coating is made of different materials. This does not mean the poor quality of such a coating - just the opposite - this is a new word in the manufacture of doors, just if for some reason you need a completely natural wooden coating, then eco-coupon in this case will not work.

PVC coated doors

Unlike classic plastic doors, which are completely made of PVC profile, these models have a traditional wooden frame, which is coated with polyvinyl chloride.

The technology of applying the film provides for the use of special chambers in which the frame of the door leaf covered with synthetic glue is placed. A film is applied on top of the surface, which is then baked at high temperature - a diffusion process occurs, as a result of which PVC becomes part of the door surface. This technology allows you to get a matte or shiny surface of any color and texture.

The application of PVC film can be made on a frame made of solid wood, which is made from a single piece of wood or glued between each other beams. The array in this case is taken from inexpensive, usually coniferous, species of wood.

The second option is the door in which the frame is made of beams. The voids are filled with cardboard honeycomb filler, and on top everything is sheathed with MDF panels, on which PVC film is applied.

When choosing between veneered, laminated, eco-veneered or PVC film doors, a large number of factors must be taken into account. Which of them to pay attention to first of all, and which can be neglected, depends on where and by whom such doors will be operated.

Environmental friendliness

Practice shows that when deciding which interior doors to choose - laminated or veneered, made of PVC or eco-veneer, buyers do not pay so much attention to environmental issues as is commonly believed. But we look at these issues.

Veneer. Presented as environmentally friendly and harmless to humans, able to breathe. Some marketers add here a third point that using veneers reduces wood consumption. Questions arise immediately on all of the items listed. Firstly, who will guarantee that the production used varnish or glue, which in the future will not emit fumes. Secondly, the surface varnished (and the veneer is always varnished) can not be breathable. Thirdly, we must understand that it is not the consumption of wood that is reduced, but the amount of its waste that is now going into production.

Laminate. In fact, this is paper coated with a protective coating - if it is of high quality and not subject to evaporation, then there will be no harm to health from such a door.

Ecointerline interval. According to the manufacturers, the material does not emit any fumes into the air, respectively, and will not let them out if they begin to appear from the glue on the frame. It’s hard to say about wood consumption, because its fibers are used in production.

Pvc film. One of the components of this material is chloride, which is slowly but surely released into the air. The question remains, does this happen during the entire period of operation or during a certain time, but judging by the conclusion of the commissions for permission to use this material and the number of installed plastic windows and doors, basically this moment is left without due attention. It is much more often mentioned that PVC is a completely artificial material, and wood is not used in its production.

In terms of environmental friendliness, the veneer wins with a slight margin, but doors covered with an ecointerline interval and a laminate with a high-quality coating are unlikely to yield to it. Here it is still necessary to pay attention to what filling the door leaf has. The best option in terms of environmental friendliness will be doors, the frame of which is made of an array of low-value species covered with veneer. If you choose between a frame made of particleboard and MDF, then the best option would be MDF, because it is a more environmentally friendly material.

Strength and wear resistance

This is one of the main parameters that determines the service life of doors. Typically, manufacturers try to improve this indicator through the introduction of new technologies.

Veneer. The main protection for such doors is provided by a layer of varnish with which they are coated, but in any case scratches and dents that may appear to close up or mask are rather difficult.

Laminate. It was originally developed as a floor covering, so it is stable enough to resist cuts and dents. But for inexpensive doors, a material with a thin protective layer is often used, which can be susceptible to abrasion.

Ecointerline interval. Since it was created on the basis of polymeric materials, the wear resistance of the surface treated by it is at a high level - it does not crack, is not subject to chips and deformations. If natural veneer can change its appearance over time, the eco-veneer will retain its original appearance for two to three decades. Unlike natural wood products, the ecointerline interval is not subject to cracking and fading from ultraviolet radiation.

Pvc film. By technology, this material is literally baked on the surface, creating a durable coating. But when exposed to sharp objects, the film is easily damaged. Subsequently, it may lag behind the base.

If you do not take into account the quality of the materials used, eco-veneer and laminate are unambiguously leading in this category.

Humidity and Climate Change

Here it is necessary to take into account not only the finish but also what the frame of the door is made of - an array of glued pieces of wood or chipboard and MDF. In the first case, the influence of humidity and temperature will be much more noticeable.

Veneer. In any case, such doors are not recommended to be placed in rooms with high humidity. If the frame is made of solid wood, then it will be susceptible to temperature extremes.

Laminate. It tolerates moisture well, but if the outer layer is damaged, it will begin to deteriorate.

Ecointerline interval. The material is not susceptible to moisture and temperature changes. Such doors are recommended to be placed in the bathroom and toilet.

Pvc film. Plastic absolutely does not absorb liquid and is not subject to deformation under the influence of temperature, therefore it can be installed not only in humid, but also in technical, unheated rooms. In conditions of variable humidity and temperature, such doors will keep their shape unchanged.

In this parameter, artificial materials win, and there is no particularly noticeable difference between them.

Practicality and complexity of care

Veneer. Wooden doors often require special care, since chemically active cleaning agents are contraindicated for them. As a result, it is better not to install them in places with a large movement of people.

Laminate. Wet cleaning is well tolerated, but since the layer of the laminate is usually quite thin, it is better not to use abrasive substances when cleaning it.

Ecointerline interval. Manufacturers do not impose any restrictions on care products for doors covered with eco-veneer, but remember that they have a relief surface, so you should not use very rough cleaning agents. They also tolerate the effects of detergents.

Pvc film. Surfaces coated with it can be washed with any cleaning agents - in addition, they do not require any care. The surface of PVC has no pores, therefore it can be washed freely with detergents.

The easiest way to care for doors with an external coating based on polyvinyl chloride - their dense surface prevents the penetration of dirt inside and it is easily washed off by any means available. However, on the same surface, various sweat marks are best seen.

Design and appearance of the coating

None of the materials for the outer coating of door leaves imposes any significant restrictions on their design. Doors can be paneled, with glass, other decorative inserts or with a drawing on its surface.

Veneer. The surface has a characteristic woody pattern - most often is varnished, less often - painted.

Laminate. Manufacturing technology allows you to apply any pattern to the surface, but mainly buyers choose solid colors “wood-like”.

Ecointerline interval. Mostly this is the design of solid colors with the characteristic structure of the outer coating for wood. In addition to the fact that the eco-veneer imitates the wood structure, its advantage is the ability to paint the surface in different colors during production and get, for example, blue wood. At the same time, the colors at different doors will be exactly the same.

Pvc film. Manufacturing technology does not impose any restrictions on the coloring and design of such doors, especially since there are opportunities to use embossed embossing. Doors with PVC coating can be made very similar to the construction of solid wood or veneer, which allows you to use them together with such models in the same interior.

A feature of coatings made of natural materials is the heterogeneity of their colors - the color of doors even from one batch may vary slightly. Moreover, no coating can convey the beauty of natural wood except veneer and eco-veneer.

Door cost

Leadership in this category will be quite arbitrary, because doors with each type of external coating can be made in different price categories - with different fillings and thicknesses of the coating itself.

Veneer. Natural materials have always been in price, especially since their deficit is increasing over time - veneered doors, all other things being equal, will be the most expensive.

Laminate. The cost of a laminated door is cheaper than veneer and eco-veneer, but more expensive than PVC coated doors.

Ecointerline interval. Eco-veneer is in second place in terms of cost, which is determined by the content of wood fibers in its basis and recognized environmental friendliness. However, the cost of the final product for the buyer will be much lower than that of analogues made of natural wood.

Pvc film. The relatively low price is one of the most inexpensive and affordable economy class doors.

Also of great importance to the cost will be the type of door - folding, sliding or solid. The first two options require additional fittings, the quality of which has serious requirements.

Comparison of various door coverings

|  |  |  | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Veneer | Ecointerline interval | Laminate | Pvc film | |||||||

|

|

|

|

|||||||

| Environmental friendliness | Natural material, but glue is used to apply it. | Artificial material which contains wood fibers. | Artificial material, but high-quality coating is environmentally friendly. | One of the components is chloride, which is released into the air. | ||||||

| Strength and wear resistance | The main strength is provided by the protective varnish and the reliability of the coating depends on its quality. | It has high wear resistance. | If the coating is of good quality, then it resists the formation of scratches and dents. | It is easy to damage with sharp objects, after which peeling from the base can be observed. | ||||||

| Humidity and Climate Change | Very capricious, under the influence of moisture, peeling from the base can be observed. | Not susceptible to moisture and temperature changes. | Resists moisture, but if the layer is damaged, it begins to deteriorate. | Does not absorb moisture. | ||||||

| Practicality and complexity of care | Requires special care. | There are no special requirements, but it should be remembered that the surface is embossed. | There are no special requirements, but it should be remembered that the surface is embossed. | The surface has no pores, it can be washed with detergents. | ||||||

| Design and appearance of the coating | The texture and color of natural wood. | They have the texture of natural wood, while the color can be any. | It is possible to apply any images, but mainly under the texture of the tree. | A variety of colors and designs, but a closer look shows that this is a film. | ||||||

| Door cost | High. | Lower than veneer. | Medium. | Low | ||||||