Electric scissors for metal: everything is like clockwork

Cutting sheet metal using hand-held scissors or a grinder is a difficult, labor-consuming and traumatic process, but the greatest difficulties arise when processing corrugated and shaped metal products. And if they are also located in inaccessible places, then it is almost impossible to perform any operation. Without problems, electric scissors for metal will help to cope with any task. This article will tell you how they are, how they differ, how they function, and what you need to consider when choosing a tool.

Content:

Design features of metal shears for metal

Externally, electric scissors for metal resemble a small angle grinder (grinder). Compact models have a narrow oblong-shaped case, conveniently located in the hand. Larger and more powerful options are more difficult to grasp with the palm of your hand, so they are equipped with a remote handle. For the manufacture of the body of electric shears, shock-resistant structural ABS plastic is used.

1. Multistage gear;

2. Work unit;

3. Protective plate;

4. Plastic case with built-in electric motor;

5. Electric cord.

Inside the plastic tool body is an electric motor, and in the front there is a multi-stage gearbox in a metal casing. In this unit, the rotational movement of the spindle is converted into reciprocating, as a result of which the cutting equipment is driven. The working unit works on the principle of a manual mechanical tool: it includes static and movable elements in its design, when passing between them, the sheet metal is cut.

Electric scissors for metal differ in the way the material is deformed - there are knife models that cut the canvas like household scissors, slotted and punching machines resembling a clerical hole punch with their work.

The working bodies of various types of electric shears for metal:

Leafy

Slotted

Cutting

The advantages of electric scissors for metal

We will talk about the functional features of specific modifications of the electric shears later, but now I would like to dwell on the advantages inherent in all these devices. So:

- Compared with manual scissors for metal, the appliance does not require special physical effort, because the cutting or cutting process is performed automatically;

- for the same reason, productivity increases significantly;

- electric shears for metal can be used for cutting fairly thick (up to 5 mm) metal elements, as well as for working with non-ferrous alloys, polymers and composite materials, the processing of which, of course, is not possible for a hand tool;

- not only smooth sheet metal, but also profile products (for example, metal tile, corrugated board, etc.) can be easily cut with a power tool of this type;

- the ergonomic design of the electric shears allows the manufacture of complex curved parts, including and by templates;

- Due to the sharp cutting element and high speed, the cut is accurate and clean;

- during the cutting process, the workpiece is not deformed or damaged;

- the safe design of the instrument and the absence of the need for direct tactile contact with a metal product nullifies the risk of injury during operation.

Types and modifications of electric shears for metal

There are three main types of electric shears, differing in their functional purpose, design and principle of operation. So all models are divided into sheet, slotted and die cut modifications. Next, we consider in detail the features of each species.

Sheet Scissors

According to its design features and the principle of operation, this tool most closely resembles household scissors. On a rigid support element of a horseshoe-shaped in the horizontal plane, a static knife is fixed. In the perpendicular (vertical) plane, a movable knife works through reciprocating movements. By reinstalling the support platform, you can adjust the gap between the upper and lower knives, adjusting the electric shears to work with a material of a certain thickness.

+ Benefits of Sheet Metal Scissors

- high speed and productivity (it is advisable to use for dismantling metal structures);

- accuracy of a direct cut and some types of shaped cutting;

- convenience of snacking materials (wire, folds, etc.);

- during the cutting process no waste material in the form of long and small spiral chips;

- the possibility of cutting metal sheets with a thickness of 4-5 mm;

- the possibility of long-term use of one cutting blade (square-shaped knives with cutting edges at the edges, when one of the edges is blunted, you can change the position of the knife, moving it with the sharp side to the working position).

– Disadvantages of sheet shears

- The main disadvantage is that you can start cutting the workpiece with sheet scissors only from its edge.

- In addition, such devices are characterized by insufficient maneuverability when making curved cuts and profile blanks.

- In addition, they have a somewhat bulky design.

Slotted electric shears

This modification also has a pair of knives in its design. One of them is fixed on top, it is fixed, has a U-shape and two cutting edges. The lower knife performs reciprocating movements in a vertical position, going into the groove of the fixed upper element of the electric shears. When cutting, thin spiral chips are formed. The function of adjusting the gap between the knives is also available here, which allows you to adapt the device to the thickness of a particular metal sheet.

In high-quality models, the chips come up and to the side, without interfering with the review and without damaging the workpiece. Chips are periodically cut with special nippers.

+ The advantages of slotted electric shears

- the ability to start cutting from any part of the workpiece (can be used to make holes);

- the machine copes with local bumps in the steel sheet (folds);

- when sawing, the sheet is not deformed;

- slotted electric scissors for metal hold a given line well;

- the narrow nose of the device provides convenience in hard-to-reach places.

– Disadvantages of slotted electric shears

- slotted models are the weakest of all modifications, as the maximum thickness of the material that they can handle is only 2 mm;

- have an impressive turning radius;

- short work of the lower movable knife.

Nibblers

Scissors for metal electric nibblers are essentially a miniature punching press that can be manually moved around the web in a given direction. The design of this equipment includes the same elements as the stationary metalworking equipment - a matrix and a punch.

The matrix is a static element of a square or round shape, fixed in the matrix holder. A punch acts as a punch, which is a movable part of the equipment. It is mounted in a slider that performs reciprocating movements transmitted by the crank mechanism. The shape of the punch is fully consistent with the shape of the matrix.If it is necessary to replace one of the elements, they are changed in pairs.

Round die-cutting elements are designed to work with thin sheet materials (up to 3 mm), and square - for thicker workpieces. The die and punch have a stepless 360-degree rotation function, which makes it easy to make curved cuts. To make it easier to reach very hard-to-reach areas, the matrix can be fixed with an angular interval of 90º.

During the operation of die cutting machines, the punch cuts holes in the metal sheet, from which a continuous path is formed, with a width equal to the diameter of the punch.

Some kind of die-cutting shears are die-cutting shears for corrugated sheets with high trapezoidal corrugation.

+ Advantages of Die Cutters

- high maneuverability and versatility (the ability to perform curved cuts, cuts according to the pattern and various holes);

- the smallest turning radius among other models of electric shears;

- extended functionality (you can quickly replace cutting elements);

- good visibility of the work area;

- the possibility of cutting not only from the edge, but also from the middle of the workpiece (you must first drill a hole);

- very clean cut, no deformation on the workpiece;

- the ability to work with thick workpieces (most nibblers have considerable power).

– Disadvantages of die cutters

- formation in the process of carving waste in the form of sharp metal “confetti” of a crescent shape, abundantly sprinkling operator’s shoes and clothes;

- it is difficult to keep a straight cut line;

- poor patency in places of thickness difference (for example, biting of the fold).

How to choose a metal shears for metal

And now let's talk about how to choose electric shears for metal. First of all, it is necessary to determine the specifics of the prevailing work. According to experienced craftsmen who used different types of electric shears in their practice, the most versatile are cut-off machines, namely sheet models. For example, for the installation of ventilation - this is ideal. Slotted electric shears can be classified as cutting tools. They are excellent for working with thin sheet steel in hard-to-reach places, for example, for carrying out body repairs. Vysechnye models are convenient to use when carrying out roofing works, since they do an excellent job with sharp relief surfaces - corrugated board, metal tiles, corrugations, etc.

However, when choosing, it is worth focusing not only on the nature of future work, but also on the technical characteristics, as well as the capabilities of the tool itself.

Type of food

There are battery and network models. For example, for roofing the main factor is mobility, as It is not possible to connect the car to the network on the roof. Plus, there is no risk of cord damage to the sharp edges of the roof elements. However, it should be noted that mobile electric shears have restrictions on power and operating time. Using a battery-powered device, you can cut a steel sheet with a maximum thickness of 1.5 mm, and the total cut area per charge will be, at best, 70 m. When choosing a mobile model, you should pay attention to the number of spare batteries and their charging speed.

Engine performance

The power of the average electric scissors can not be called high - it varies between 300-650 W. Naturally, this indicator affects the productivity of the electric scissors and their ability to cope with a certain metal thickness. When choosing a more powerful tool, you should consider that it will have a solid mass and a larger turning radius due to the size of the knives. The choice in this case will depend on your needs.

Cutting Frequency

The speed and "purity" of the process of cutting metal parts will depend on this criterion.The higher the speed of the electric shears, the more accurate the cut line. As a rule, light, but not particularly powerful tools, work quickly and cleanly, and high-torque units are slower and more inaccurate. When comparing the stroke frequency, one should take into account the parameters of indicators of the same type of models, i.e. sheet - with sheet, die-cutting - with die-cutting devices. The best option is electric scissors, which have a function of adjusting the stroke frequency, which allows you to adapt the tool to certain conditions and specific characteristics of materials.

The indicator of the maximum thickness of the metal

This characteristic is determined by the output power of the electric shears and their design features. Attention should be paid to indicators such as the stroke length of the cutting element in order to determine the maximum thickness of the metal for cutting, as well as the category of metal that can be worked with (mild steel, hard steel, aluminum).

Maneuverability

Here, the main indicator is the turning radius of the tool. Almost all manufacturers indicate the minimum radius in the passports for electric scissors, but many models significantly exceed this limit. Do not forget that sheet machines can only start sawing from the edge of the sheet, with slotted ones it is convenient to work in narrow sections, and punching machines are distinguished by the ability to rotate 360º around their axis and perfectly cope with profiled products.

Ergonomics

Electric scissors for metal are designed to be held with one hand so that the workpiece can be fixed with the second hand. In this regard, the shape and design of the machine body (thickness, the presence of corrugations and overlays) are of great importance. However, the ability to hold the device with both hands when performing certain operations is also important, so you should pay attention to whether there is a removable handle in the kit.

Launcher Option

The main requirement is the ability to lock the switch in operating mode. You should also check if the switch “knocks out” during vibration. The location of the button is also an important criterion. It should be located in such a place on the case that it was convenient to reach it with your fingers, but the possibility of accidental pressing was excluded.

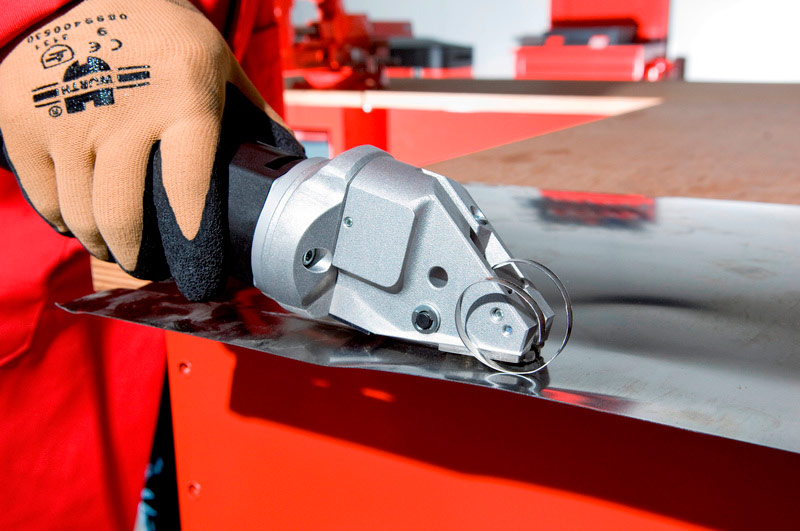

Traumatic protection

It is recommended to choose models equipped with a special shield plate designed to protect the user's hands. By the way, this option is not provided in every device, although it is very important to ensure safe operation.

Cutting Functionality Level

When choosing a tool, take an interest in the range of adjustment of the distance between the knives and whether such a function is provided at all. In addition, evaluate how easy it is to replace cutting tools (knives, die, punch). Ask if the electric shears are equipped with spare equipment, and if not, is it possible to purchase it yourself, as well as whether similar components from other manufacturers are suitable.

The choice of electric scissors for metal, depending on the work performed

| Edge Processing, Trimming | ||

| Straight cuts → | High quality cut edges → | Shears |

| Poor edge quality → | Nibblers | |

| High cutting speed → | Shears | |

| Low cutting speed → | Carved scissors | |

| High feed force → | Shears | |

| Low feed force → | Nibblers | |

| Curved cuts → | External Curves → | Shears |

| Inner curves, large radii → | Nibblers | |

| Inner curves, small radii → | ||

| Separation cut of metal sheets | ||

| Straight cuts → | Thin metal sheets → | Slotted scissors |

| Thin and thick metal sheets → | Nibblers | |

| Curved cuts → | Thin and thick metal sheets → | Nibblers |

| Small radius curved cuts → | Thin and medium metal sheets → | Nibbler shears |

| Slots in metal sheets | ||

| Curved cuts → | Thin and thick metal → | Nibblers |

| Small radius curved cuts → | Thin and medium metal sheets → | Nibbler shears |

| Cutting profiled sheets | ||

| Corrugated sheets → | Nibbling scissors (special matrix), nibbling scissors for trapezoidal profile. | |

| Low Keystone Corrugated Sheets → | ||

| High Keystone Sheets → | Nibblers for trapezoidal profile. | |

How to use electric scissors: detailed instructions

Getting started and first precautions

The blades (punches) are very sharp and move quickly, so you need to handle the tool very carefully. You can’t immediately connect it to the network - first you need to make sure that the “start” button is not activated. If this is not the case, put it in a safe position. Here - only now you can plug in the plug.

Before cutting:

- It is necessary to firmly fix the metal sheet to be cut. Otherwise, he will walk with a shaker, which will ruin the cut line. If it is not possible to firmly fix the sheet, at least press it firmly against a flat surface (for example, a table, workbench).

- To protect eyes and hands, it is necessary to put on gloves with a mask.

Secrets of a flat cut line

To get beautiful and high quality, you need to work carefully and carefully. Especially if you have to deal with such complex materials as a profiled sheet or metal tile.

Here are a few rules that will help you do everything "five":

- Cut by holding the tool firmly and pointing it perpendicular to the work sheet. By tilting the apparatus to the side (even the smallest one), instead of a straight line we get squiggles with steps.

- When you need to cut something in the middle of a metal sheet, you must first drill a hole in this place with a drill. Then, from there, start cutting with slotted or punching electric scissors.

- If you want the work to go faster - take engine oil (or a mixture of 7 parts kerosene with 3 parts turpentine). The composition is applied along the cut line. In addition, every 10-15 minutes it will not be amiss to smear a matrix with a punch with oil.

The distance between the blades of sheet shears and its adjustment

This parameter can be changed not for all types of electric shears, but only for sheet devices. This is necessary if you first cut a thick, and then a thin sheet (or vice versa). Assume that the steel sheet being processed has a thickness of 0.7 millimeters. In this case, the knives should be closer to each other. If the next task is to cut aluminum with a thickness of 2 - 3 millimeters, then the blades will need to be moved apart by an appropriate distance. For adjustment it is necessary to unscrew special screws (adjusting). After setting the desired distance between the knives, the screws should be tightened tightly.

The whole truth about vibration

If the instrument is of high quality, then nothing should vibrate anywhere. And if you feel that vibration is present, then this may indicate a possible malfunction of the device. The second reason for vibration is cutting material that is not suitable for this tool. For example, more dense than permissible. Or corrugated.

In order not to spoil the tool, read its instructions. It describes in detail what materials the scissors can work with, as well as their maximum permissible characteristics (density, for example).

Tips to increase the durability of electric scissors

Of course, everyone wants the purchased equipment to work as long as possible. In the case of scissors, the following will help:

|

Tip # 1. Timely replacement of cutting blades. By working with a blunt tool, you can very quickly destroy it. And the cut lines will turn out curves, with jagged edges. |

|

Tip # 2. When working, do not forget to periodically allow the device to rest so that the heated engine has time to cool. The instructions say how long the continuous operation can last (usually 10 or 15 minutes). |

|

Tip # 3. Do not cut where it is too damp or dusty.In the first case, a short circuit may occur, in the second case, the ventilation holes may become clogged (because of which the engine will quickly start to overheat). |

|

Tip # 4. Having finished work, with a brush it is necessary to clean the ventilation holes and working bodies well, which will keep them sharp for a longer period. |

About work safety

The following simple rules will help you not to get injured or break a brand new device:

- Pick up the electric shears before turning them on, inspect them. Check if the bolts holding the blade are loose or if there are any cracks.

- Do not work if the cable or the electrical plug is damaged (double insulation is a reliable protection against electric shock, and it must be intact). The power supply in the network must comply with the norm - 220 volts.

- Using cutting scissors or slotted type, take care of protecting your eyes - wear special glasses. Chips flying out during operation are a dangerous thing. In addition, it is very hot, so do not touch it with your hands. It is better to protect yourself with gloves.

- The cut line turns out as sharp as a knife, so it’s better not to touch it, either - you can cut yourself badly.

- The gear unit may become very hot during cutting. In order not to get a burn, do not touch it during work or immediately after it is completed.