Cable channels for electrical wiring: types, types, sizes, application

If for some reason it is not possible to make hidden electrical wiring or you need to regularly inspect the wires, then mounting brackets, terminals, boxes, clamps and other similar devices are used as fasteners. But their common drawback is that the wires remain open, and this is far from always permissible. To hide the wiring, electrical cable channels are used, the types and sizes of which we will consider in this article.

Content:

Plastic cable channels, their varieties and sizes

Most often, plastic types of cable channels are used for laying information cables in offices and, if necessary, make open or temporary wiring - in this case, they also lay power cables and wires for lighting lines.

Shape, materials and sizes

Initially, these were white or gray profiles, of rectangular cross section in the form of the letter “P” (single-section) or “Sh” (for two or more sections). Then began to produce cable channels of various shapes and colors, designed for laying cables for various purposes. Triangular cable channels or in the form of a hemisphere have appeared - it has become more convenient to use them for wires for various purposes depending on the purpose of the room, the materials used in its decoration and the need for free access to the cables hidden inside.

U-shaped cable channel.

Triangular cable channel.

Sh-shaped cable channel.

The cable channel is a hemisphere.

Non-combustible PVC or polyethylene is used for the production of cable channels. The length of one section is usually 2 meters, but manufacturers can use other standards, so if necessary, you can find cable channels longer. The width and height in the section is from 10 to 60 mm, but there can be exceptions.

The most popular are U-shaped cable channels. U-shaped cable channels can be made with solid or perforated walls. As their advantages can be noted less weight and lower price.

The dimensions of the cable channels of the U-shaped type and their useful section:

| Profile | The size (width × height), mm | Useful section mm2 | Thickness walls, mm |

|---|---|---|---|

|

12x12 | 130 | 1 |

|

15x10 | 135 | 1 |

|

16x16 | 230 | 1 |

|

20x10 | 180 | 1 |

|

25x16 | 360 | 1,1 |

|

25x25 | 563 | 1,1 |

|

40x16 | 576 | 1,3 |

|

40x25 | 900 | 1,3 |

|

40x40 | 1440 | 1,3 |

|

60x40 | 2160 | 1,7 |

|

60x60 | 3240 | 1,7 |

|

80x40 | 2880 | 1,7 |

|

80x60 | 4320 | 1,7 |

|

100x40 | 3600 | 2 |

|

100x60 | 5400 | 2 |

* Useful cross-section of cable channels of some manufacturers may be disregarded in the table.

Surface Mount Method

Depending on the material of the surface on which the cable channel must be fixed, collapsible and non-collapsible fasteners are used. The first include a dowel-nails (6CH40), metal staples or self-tapping screws - for them holes have been cut in some cable channels from the factory. Non-removable fasteners are used on plasters and similar materials - cable channels are simply glued to them (although the weight of the box with wires should be taken into account here).

Additional items

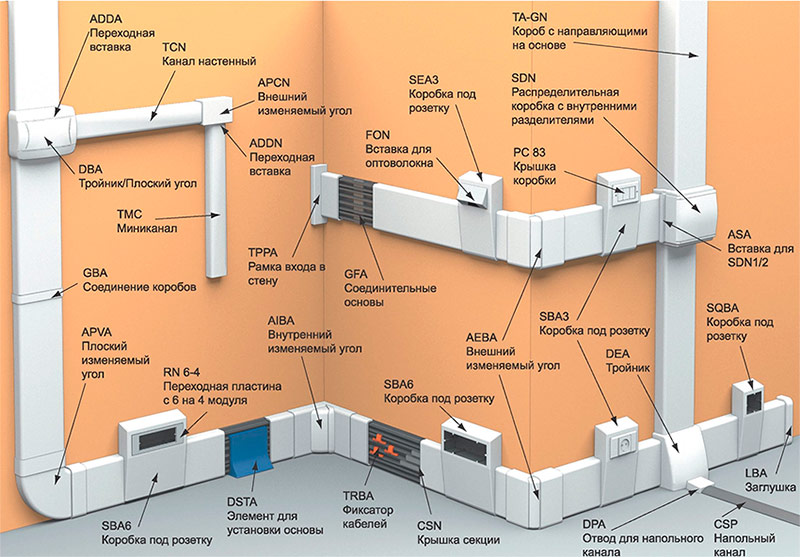

In order not to have to manually cut the trunk for turns or forks of the highway, manufacturers produce additional elements - turning angles, tees, plugs, etc. for each type of cable channels. They allow you to create a wiring of any complexity without compromising the interior and loss of installation time.

Separate fasteners for sockets and switches are also provided - these elements of the electric circuit are mounted in special elements that are fixed directly in the cable channel.

Floor and skirting cable channels

Floor and skirting cable channels are a separate category.

Floor cable channels.

All floor and baseboard cable channels also have their own additional elements simplifying the laying of highways.

Skirting cable channels inside are hollow and can accommodate a lot of wires. This is a great option for laying antenna or computer cables.

+ Pros of cable channels

- There is no need to ditch walls for laying wires.

- The laid cable is always open for inspection - you can always lay an additional line nearby.

- Despite the apparent softness, the cable channel additionally protects the wires laid in it from mechanical damage.

- Installation of the line is as quick as possible.

- Various forms of cable channels allow you to fit the external wiring line into most interior solutions.

- Cons cable channels

- Sometimes cable channels do not look at all in the interior of the room.

- The box “takes” a few centimeters of space from the wall.

- The cable channel can easily be accidentally hooked - knocked off the mount or broken.

- High-quality laying is possible only when using a large number of additional accessories - turns, branches, etc.

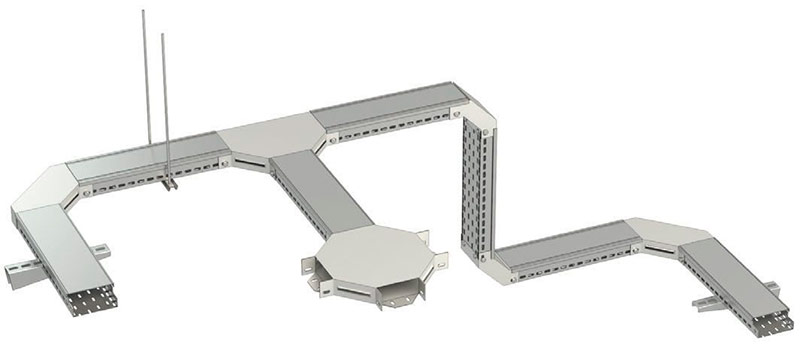

Metal boxes - types and sizes

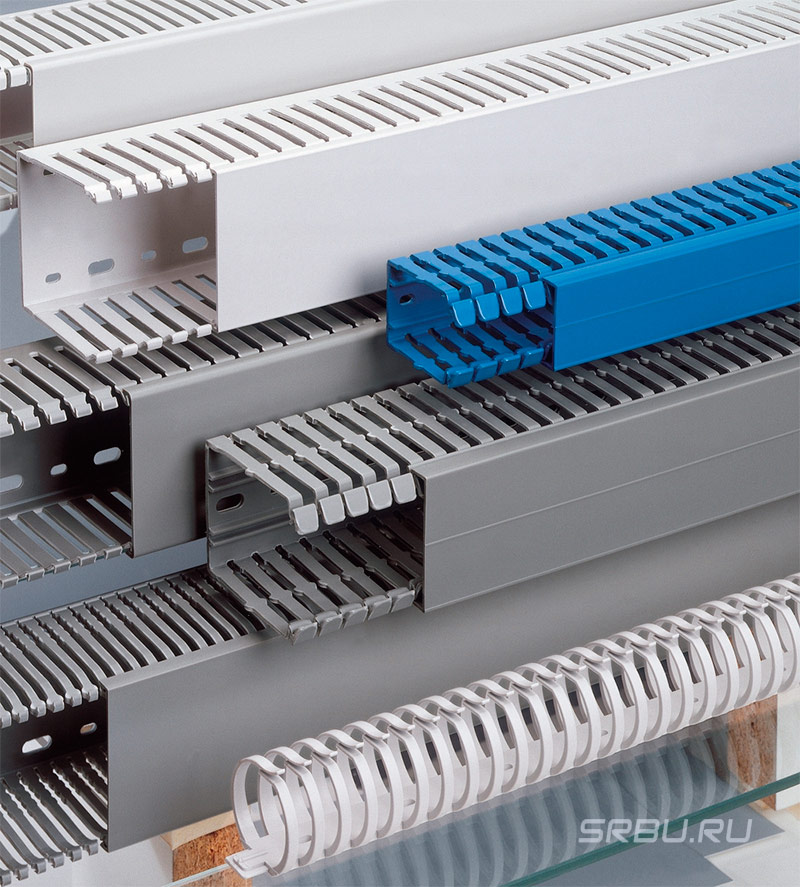

Since metal trays and boxes are designed for heavy loads, the need for their use in domestic conditions is quite rare. The types and sizes of metal cable channels are mainly suitable for external and internal cable laying in industrial premises where there are highways consisting of a large number of wires. So that the material of the boxes does not rust, galvanized steel is used in their production. Like plastic ones, the cross-section of metal cable channels is U-shaped - with or without a cover.

Depending on the conditions of use, perforated, smooth and ladder trays are made. The former are easier to mount and fasten cables inside them, while the latter are heavier and are mounted on special supports.

Cable Tray Dimensions:

| Dimensions (width × height × length), mm | Metal thickness mm | Useful cross-sectional area, cm2 |

|---|---|---|

| 50×50×2500 | 0,55 | 24,22 |

| 100×50×2500 | 0,55 | 48,44 |

| 200×50×2500 | 0,7 | 98,44 |

| 300×50×2500 | 0,7 | 147,44 |

| 400×50×2500 | 1,0 | 198,44 |

Due to the large weight, gluing of metal boxes is not practiced - they are attached to the surface with anchors, dowels or “sit” on a bolted connection. For the installation of smooth trays, shelves or brackets previously fixed on the surface are used.

Most often, metal boxes are used to form electric lines in raised floors or on false ceilings. For their installation, additional blocks are used - rotary, lifting (for transferring wires between planes), branching, etc.

+ Pros of metal cable channels

- Support the weight of a large number of power cables.

- They make it easy to trace the route of any cable, provide ease of installation and easy access for inspection or replacement.

- An additional plus to fire safety.

- Cons of metal cable channels

- Larger weight implies more serious installation work.

- Harder to handle during installation (if you want to trim).

- Such types of cable channels for wiring without fail require the availability of additional components for the installation of turns and transitions.

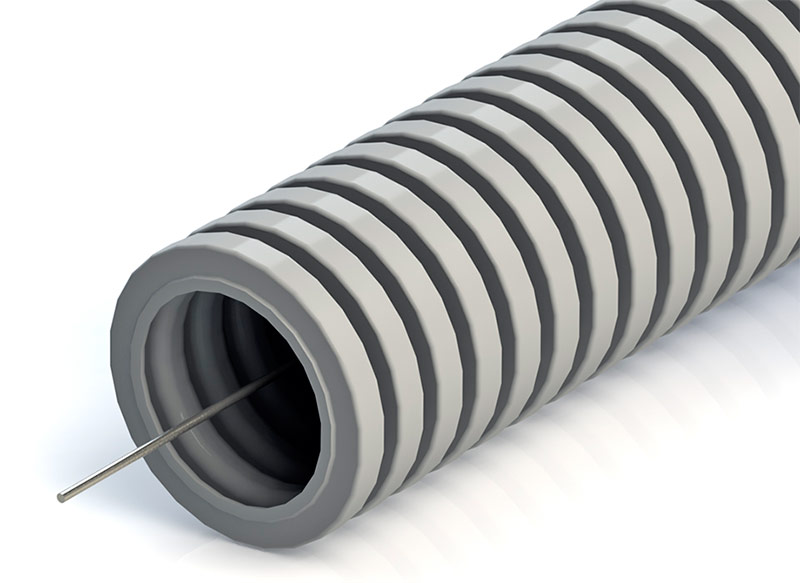

Corrugated plastic pipe

If cable ducts, plastic or metal, are more suitable for smooth surfaces, then in the case of frequent transitions between planes or turns, their installation will be extremely difficult due to the need to use a large number of additional components. In such conditions, flexible pipes that bend at any angle and fasten along the entire length to standard clips are more suitable material.

Externally corrugated plastic pipe looks like an elastic channel of circular cross section. It is used for laying any cables and wires, providing them with additional protection against moisture and mechanical damage.It is mainly used in the installation of electrical circuits with a complex path of wiring - raised floors, suspended ceilings, electrical wiring behind plasterboard walls.

Sizes and accessories

For the production of corrugated plastic pipes, PVC is used. Most often, products with an internal diameter of 16 to 32 mm are used, but when choosing, you must additionally pay attention to the purpose of the corrugation - it can be light or heavy.

The first are standard products that are used for the installation of electric circuit lines inside buildings. Heavy corrugations provide more solid protection and can be used outdoors, and in some cases under water.

Since it is not always possible to push the wire through the pipe in long routes without auxiliary parts, the corrugations can additionally be equipped with probes from a single-wire metal “steel”, however, usually the installers have their own.

Dimensions of corrugated pipe for cable:

| Headline | Outer diameter mm | Inside diameter, mm |

|---|---|---|

| Corrugated PVC pipe without probe | 16 | 10,7 |

| 20 | 14,1 | |

| 25 | 18,3 | |

| 32 | 24,3 | |

| 40 | 31,2 | |

| 50 | 39,6 | |

| 63 | 5,6 | |

| Corrugated PVC pipe with probe |

16 | 10,7 |

| 20 | 14,1 | |

| 25 | 18,3 | |

| 32 | 24,3 | |

| 40 | 31,2 | |

| 50 | 39,6 | |

| 63 | 50,6 |

+ Pros of Plastic Corrugated Pipes

- Indispensable for laying wires on uneven surfaces or, if necessary, make frequent turns of the trunk.

- Usually airtight along the entire length, therefore they reliably protect the wires from high humidity.

- Additional protection of cables from mechanical damage, and people from electric shock.

- Mounting on clips is one of the easiest for installation and maintenance - you can insert or remove corrugation without additional tools.

- In addition to fire safety, the plastic of which the corrugation is made contains additives that prevent burning. When the wiring is shorted, the corrugation does not flash, but simply melts.

- Cons of plastic corrugated pipes

- Negative temperatures are poorly tolerated - when supercooling, they lose their elasticity and break, so they are more suitable for internal work.

- With an excessively large number of turns and bends, pulling the cable inside the corrugation will be very difficult, and sometimes impossible, so you will first have to tighten the wires inside and then perform a general installation.

Corrugated metal pipes

A distinctive feature of metal hoses from plastic pipes is in the manufacturing method. If the latter are completely solid and sealed, then the metal ones are twisted from galvanized steel tape, which determines the advantages and disadvantages of use.

Sizes of metal hoses for cable:

| Outer diameter mm | Inner diameter mm |

|---|---|

| 11,6 | 7,8 |

| 13,9 | 9,1 |

| 15,9 | 10,9 |

| 18,9 | 14,9 |

| 21,9 | 16,9 |

| 24 | 18,7 |

| 26 | 20,7 |

| 30,8 | 23,7 |

| 38 | 30,4 |

| 44 | 36,4 |

| 58,7 | 46,5 |

All other parameters are similar to PVC pipes.

+ Pros of Corrugated Metal Tubes

- More reliable protection of wires against mechanical damage.

- If the metal hose is grounded, it will act as an additional electromagnetic shield - in some cases, when laying information cables, this is a significant advantage.

- Easy installation.

- Cons of corrugated metal pipes

- Since the pipe is not integral, it cannot be used in conditions requiring an airtight connection.

- Weight and cost are higher than that of plastic counterparts.

- Immune to freezing temperatures.

Smooth rigid pipes for electrical wiring

Smooth rigid pipes are used for maximum protection of the wiring and ease of maintenance. If you wipe the wires in a rigid pipe in the wall, you get all the advantages of hidden wiring, but if you need repair, you don’t have to wall the walls - the cables are simply pulled out for repair or replacement.

Dimensions of rigid pipes for cable:

| Outer diameter mm | Inner diameter mm |

|---|---|

| 16 | 13,6 |

| 20 | 17,0 |

| 25 | 22,0 |

| 32 | 28,4 |

| 40 | 36,2 |

| 50 | 46,4 |

| 63 | 56,5 |

+ Pros of Smooth Rigid Tubes for Electrical Wiring

- Even in the event of a serious circuit, they protect a person from electric shock.

- Plus to fire safety.

- Relatively low weight and installation costs.

- Cons of smooth rigid pipes for electrical wiring

- Rigid pipes require the use of additional accessories to create turns and additional branching lines.

- With a large number of turns it is difficult to stretch the wires.

- For installation, additional accessories are needed: corners, plugs, tees, etc.

These are all the most common types and types of cable channels for electrical wiring in domestic and industrial conditions. Which of them to use should be decided in each case separately - depending on the specific conditions.