How to choose a generator for the home: selection of optimal equipment parameters

The use of autonomous generators is a widespread practice - in general, these are fairly simple devices and there are no problems with their acquisition. The more acute question is which generator to choose for a house or a summer residence, because improperly selected characteristics of the equipment in the best case will entail excessive high cost of its operation, and in the worst case, inability to perform its functions and breakdown from systematic overload.

Content:

Types of engines of autonomous generators

Internal combustion engines are primarily divided into two and four stroke. The fundamental difference for the user is that in order to “feed” the two-stroke one, he will have to prepare a mixture of fuel and oil, and just add fuel (or diesel) to the four-stroke one - this engine also consumes oil, but it is poured separately and is not emitted with exhaust gases.

Two-stroke machines are low-power generators - 1-5 kW, and in rare cases up to 10.

This may be enough for an autonomous power supply at home without a large number of electrical appliances, so there is a chance to encounter a two-stroke engine when choosing, although in general, for the power of the house, its advantages look somewhat illusive and the choice often falls on four-stroke ones.

The next item is the type of fuel used by the engine - gasoline, diesel fuel or gas. It should be remembered that to work on gas, gasoline engines are redone, so that you can switch between these types of fuel.

Autonomous gasoline-powered generators

Gasoline engines are rightfully the most common in household class generators, as they have a number of advantages that level out disadvantages that are not particularly critical for home use. First of all, this is the price, which is 2-3 times lower than the diesel counterpart with similar characteristics. Next is the ability to run without frost in cold weather up to 20 ° C, and sometimes even higher. Finally, the sound of such engines is quieter than that of diesel engines, and the engine itself is able to operate at minimum speed (the diesel engine needs a minimum load, at least 40% of the nominal).

At the same time, only the relatively small motor resource (within 4-5 thousand hours) and the low limit of the maximum generator power (15 kW) can be attributed to the minuses of gasoline - theoretically, it is possible to create a more powerful, but economically more profitable to use a diesel engine.

Autonomous gas generators

The use of gas somewhat reduces the fuel consumption item and generally increases the durability of gasoline engines, since there is much less soot in the combustion products. If a gas main approaches the house, then this is almost an ideal option, because the gas is turned off much less often than electricity.

Diesel Autonomous Generators

Diesel internal combustion engines are more expensive to manufacture and heavier, but more economical and more durable, therefore they are used for autonomous power plants of high power or, when increased efficiency and reliability are required. These requirements are especially relevant if it is necessary to supply powerful current consumers in a round-the-clock or just continuous mode.

How to determine the type of generator

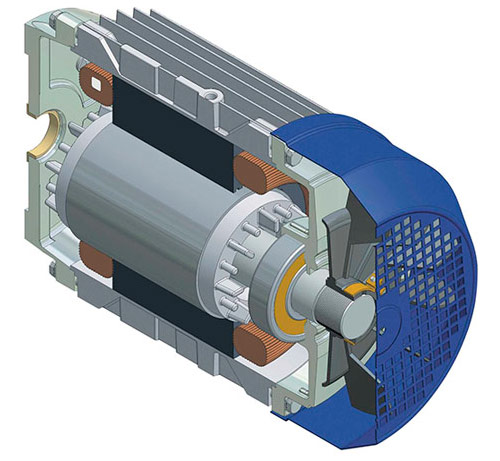

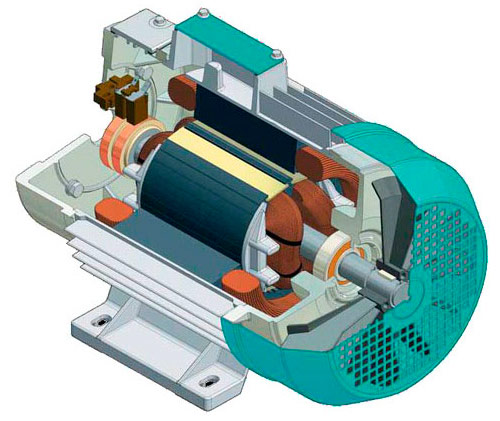

The second name for this part of the generator is the alternator.It is he who is directly responsible for generating electricity, converting the mechanical energy of rotation of the motor shaft into electrical energy.

There are two main varieties of generators, which got their name from the corresponding types of electric motors, taken as their basis - synchronous and asynchronous. If you do not go into technical details, then mainly for the average user the difference will be in ease of maintenance and quality (stability) of electricity generated.

Asynchronous generator

In terms of ease of maintenance, asynchronous generators were undoubtedly the leaders since their rotor is short-circuited; has no additional winding. This means that there is no need to additionally cool the inside of the asynchronous chamber - to make additional ventilation holes in the stator through which dust and moisture also enter the inside. The only service that might be needed over time is to replace the bearings or simply renew the grease on them. Also, the pluses of asynchronous generators can be written “friendship” with the short circuit mode (they show themselves better when working with welding machines).

Synchronous generator

As for the quality of the generated electricity, synchronous generators showed themselves better here - they have a much smaller dependence of the output voltage on the motor shaft rotation frequency (in asynchronous ones it is linear, and synchronous ones give a given voltage even with some deviations). Also, synchronous generators perform much better under conditions of constantly changing load and can withstand short-term overloads without special consequences (in asynchronous ones, in this case, there is a high risk of demagnetizing the anchor).

As a result, asynchronous devices show the best results only if they are used for welding. If you need to choose a generator for a summer house or a home, in most cases a synchronous type of generator is preferable, despite the need for periodic replacement of brushes and a higher overall cost. An additional trump card is the appearance of brushless synchronous generators with a squirrel-cage rotor, which gradually displace asynchronous models.

If you need to power accurate equipment, you should pay attention to generators with an inverter voltage generation circuit. In such devices, the generated current is rectified, conducted through the stabilizer, and then converted back to alternating current. As a result, the error of the output voltage is only 1% of the nominal, whereas in any other circuit it is about 5%.

Autonomous Generator Launch Systems

In principle, only two generator start-up systems are used - manual and automatic. The starter of the first of them is driven by a cable, which must be pulled manually, only first to do this, switch the power off the main line and then start the engine.

An automatic start is carried out by means of a rather complex system, because in addition to directly unwinding the starter, a number of additional actions must be performed:

- Monitoring the presence of voltage in the main network. When it disappears, a command is issued to activate the generator.

- Switching the power supply of the house from the main line to the generator, so that when electricity does not appear countercurrents, which are guaranteed to burn the winding.

- Every motorist knows that a cold engine must be started with a closed choke. If the generator operates autonomously, then you need a block that closes the shutter before starting and opens it after warming up the engine.

- Starter launch.

- When voltage appears on the main line, the generator engine is turned off, and the power of the house switches back.

As a result, if you need a generator capable of fully autonomous operation, you must select a device with an automatic start system.The launch system can make up a fairly noticeable part of the cost of all equipment.

Additional items

Usually, all additional equipment is designed to increase the safety and convenience of working with the generator. Part of it can be installed while manufacturing the device or added to the store (sometimes promotions are held), and the rest can be purchased at will.

First of all, these are protective devices - fuses and circuit breakers, which, after shutdown, can be switched on again in manual or automatic mode (depending on the class of the generator).

Drop sensor - even from the factory it is installed on most generators, except for the smallest in power (also they are not needed on two-stroke engines).

Indicators - tube, arrow or LED. Show information about the state of the oil level, signal the occurrence of an overload, or simply display the current operating mode.

Hour meter - Seriously facilitates the control of the time remaining until the next major overhaul or just maintenance of the engine. Often present in the factory assembly.

Voltmeter - useful when connecting a large load - shows if the generator starts to work incorrectly. It is considered an indispensable part, but it can still be absent on the most low-power devices - this is often done by eminent manufacturers, as if emphasizing confidence in their products.

Fuel tank with fuel gauge and drain cock. How necessary are the last two details, each one decides for himself, but the tank itself as a whole determines how much time the generator is able to work without refueling. If this is a frame-type device, then they generally try to install a tank on it for the entire length of the frame. It should also be borne in mind that since gasoline devices often need interruptions in operation, the corresponding tank volume can also be selected for them - if the fuel runs out, then you need to let the generator rest.

Sockets - single and three phase. Their availability is not regulated in any way and completely depends on the manufacturer. There may be an option when there is an ordinary and power outlet - if there is no experience to distinguish them “by eye”, then it is better to study the documentation for the generator, which should indicate which outlet that can be connected.

12 volt output - for which clamp terminals, a socket or a separate outlet are made. According to users, most often the presence of such a conclusion pleases motorists, since it is convenient to recharge the batteries from it. For other purposes, it is better not to use it, since devices that need 12 Volts of power to work are usually sensitive and should not be connected directly to the generator.

Number of phases of the generator

It is very simple to make a choice between a single and three-phase generator - if you want to connect three-phase consumers of electricity, then the appropriate device is selected, and if there are only single-phase devices, a single-phase generator.

In some cases, for a single-phase network, they try to install a three-phase generator, guided by the consideration that it is possible to "scatter" the phases along different lines. You can really do this, but only under one important condition - if approximately the same load hangs on each phase - the power difference should not exceed a maximum of 30%. This means that if two phases of the 15 kW generator are not occupied, then a maximum of 5 kW can be switched on to the third. At the same time, the generator itself will not work in the nominal mode and over time there is a great risk of its failure.

In a private house, it is almost impossible to achieve uniform load distribution, so if the vast majority of devices are single-phase, and one or two are three-phase, you must either purchase an additional generator, or change the electrical devices themselves to single-phase, or not use these devices,when power is supplied to the house from a generator.

Generator power selection

It may seem to an uninitiated user that there should not be any particular difficulties in choosing a gas generator for power supply. This is a simple mathematical problem - if the generator indicates that it can produce, for example, 10 kilowatts, then at the same time it is possible to hang on it such a total power. Some may even consider that the generator needs some “margin of safety”, subtract 20-30% from the maximum power and believe that everything is correctly calculated. In practice, everything is somewhat more complicated and for a competent calculation, you will have to take into account an additional series of nuances.

Power reserve

Oddly enough, but many forget about this elementary truth or simply try to save on choosing a more powerful generator to provide those same 20-30% of the power reserve. As a result, the generator can work for wear, which sharply reduces its service life.

Also, an asynchronous generator can throw an unpleasant surprise, which, although immune to short-circuit currents, is extremely sensitive to overloads, even short-term ones. The fact is that its launch and operation is ensured by the residual magnetic field of the armature - after the generator stops, the rotor retains some magnetization, which is enough to induce EMF on the stator windings during the next start-up of the device. At times of peak overloads, the magnetic field of the armature simply disappears and the generator ceases to generate current, although the engine continues to rotate. In this case, it is necessary to magnetize the rotor forcibly - although this is a simple procedure, the need for its repetition at times of overload is rather unpleasant for the user.

Also, the power reserve is needed to power electrical appliances with electric motors, which require 2-3 times more current from the nominal value to start.

Active and reactive power (volt-amperes and coefficients)

The simplest example, when it may appear that the generator is faulty, occurs in the case of unaccounted reactive power of electrical equipment. In simple words, it can be called a parasitic phenomenon, when part of the power is spent not on the operation of the appliance, but on losses (heat generation, etc.).

Without plunging into the jungle of electrical engineering, an ordinary user needs to know that any electrical appliance that has an electric motor has reactive power to carry out the correct calculations - a phase shift occurs in its windings and additional energy losses occur. Therefore, the power here is determined by the product of the current strength and voltage relative to the power factor (Cos φ), which for each device is its own and can be from 0.3 to 1 (the more, the less loss).

The same applies to the generator itself - since it is essentially an electric motor, it has its own coefficient, which is usually 0.8 (although there may be other values). This means, if the power indicated on the generator is 15 kW, then this is the active component, and when connecting the reactive load, you will have to take into account the coefficient and in the end it will turn out 15 * 0.8 = 12 kW (multiplication, not division by the coefficient, is done, since the generator current is generated) and this is without taking into account the coefficients of the supplied electrical appliances.

The real power of electrical appliances is also calculated. For example, there is a vacuum cleaner with a rated power of 1000 W and a coefficient of 0.6. In this case, it will not take 1 kW from the generator, but 1000 / 0.6≈1.7 VA (Volt-Ampere). Such calculations will not have to be carried out if the manufacturers initially indicated power instead of the usual kW in Volt-Amps, although if part of the equipment is marked with kilowatts and the other with volt-amperes, then it will be necessary to practice transfers between measurement systems.

As a result, if the equipment does not indicate the exact values in the form of Volt-Amps and the Cos φ coefficient, then it is easiest to add 50% to the power of electrical appliances with electric motors and use this value in the calculations.

Capacitive load

The concept of capacitive load is most often encountered by professional photographers - it is they who can use lighting devices based on discharge lamps or the like on the road.

The very nature of obtaining the capacitive component of the electric current involves the use of an asynchronous generator, since it generates voltage in a "soft" way - the stator field rotates after the rotor.

Using a generator to power a house or cottage

Choosing a generator for a private house, one of the main questions will be understanding how it will be used - as a backup or permanent source of electricity. Only knowing the exact answer to this question can you select the type of engine, the power of the inventory and decide whether to take a high-quality branded device or a budget Chinese model.

In any case, if you need a generator for the whole house, even if it's just a summer residence, it makes no sense to look towards portable models with a power of 0.8-1.5 kW. They are only enough for the operation of lighting devices and a TV, and even a low-power refrigerator at startup can cause overload.

You also need to be prepared to give the generator a separate room, and it’s very good if you can make soundproofing and heating there. The last question is especially important when using a diesel engine.

Ready-made solutions in which a gas, gas or diesel generator is enclosed in a special housing are becoming increasingly popular. Such power plants are mounted on a concrete site near the house. If the means allow, it is better to give preference to such systems, as these are the most practical, convenient and reliable devices.

If necessary, you can make a similar container yourself. Below you can see an example of a similar construction made of corrugated board.

And one of the main questions is how to connect the generator to the home network. Only “or-or” type circuit breakers are suitable for this - they completely exclude the possibility of electric current from the main power supply line getting onto the generator windings, which, without options, leads to their burnout.

Using a generator as a backup or emergency source for a residential building

If the electricity on the main line is turned off only from time to time, then you can congratulate yourself on the opportunity to save. In addition to the fact that there is no particular need to purchase a powerful generator, a Chinese-made device with a gasoline engine is quite suitable for these purposes. The operating life of such a generator is about 1-1.5 thousand hours, and if you run it once a week for 3-4 hours, then it is easy to calculate that it will be enough for 12-15 years.

Another question is if the electricity is turned off almost daily (there is no point in thinking where the energy supply companies are looking at it - more often they can solve the problem on their own faster) - in this case it is more profitable to purchase a branded generator. Even devices with a gasoline engine from a trusted manufacturer have a resource of 4-5 thousand hours.

The next saving point will be the engine starting device - if the electricity is turned off from time to time, you can turn on the generator manually. Of course, this takes some time, but eliminates the need to overpay for a separate automatic start system. However, the decision about the need for its use in any case must be taken locally.

Also, when using the manual inclusion of the generator, it is necessary to take care of the alarm system for the appearance of electricity in the main network.To do this, you can draw a separate line into the room an ordinary light bulb that will turn on past the generator - when it lights up, then you can switch to a common line.

Using a generator as a permanent source of electricity

If the use of generators with gasoline engines is more economically justified as a backup source, then for permanent operation without options you will have to choose exclusively from models with diesel ICEs and from trusted manufacturers of such equipment.

Since the generator will work almost without interruptions, it is imperative to pay attention to the presence of water cooling in it - this complicates and complicates the entire structure, but for a stationary device this is far from the most critical factor.

You also need to carefully approach the issue of selecting the power of the device - if there are no skills in calculating active and reactive powers, then it is better to entrust this matter to specialists. Even if the seller of the generator cannot consult on this topic and the service will be ordered for a fee on the side, it will pay off in any case.

Most likely, to work as a constant current source, it makes no sense to purchase a generator with an automatic start system. In this case, the need for it is a rare exception, and if you suddenly need it, it can always be installed separately.