Cork flooring: types, selection rules, advantages and disadvantages

An increasing number of consumers preparing to repair their homes and apartments are opting for cork. This is not surprising, because this flooring has a huge number of advantages with a minimum of disadvantages.

If you are ready for such a step, but do not know which cork floor is better to choose, then you still have a rather vague idea of cork as a floor material. This review will help you fill your knowledge gaps.

Content:

What is a cork floor

A cork floor is made from the bark of the so-called cork trees. These primarily include cork oak and western oak. Some other plants are also suitable for cork, for example, pyramidal balsa or Amur fellodendron, but in this case the material will not possess all the valuable properties inherent in a true cork.

Harvesting cork is a process that does not harm the plant. Masters periodically remove the bark from trees that have reached the age of 25-30 years, but over time, the plants acquire a new layer of cork - after about 10 years, the tree completely restores the lost. The tree can be subjected to this procedure up to 20 times, and each time the quality of the resulting material improves.

The process of removing bark from balsa wood.

The habitat of cork oak is located in the Mediterranean region. A significant part of the cork forests of the planet is concentrated in central and southern Portugal - here the climate is the most ideal for this plant. It is not surprising that the main producers of cork are Portugal and its neighboring Spain.

Italy, Tunisia and Algeria are somewhat behind them. However, cork is mined in almost all countries of southwestern Europe and northern Africa, i.e. wherever cork oak grows.

Cork is also produced in China, however, there is used for this purpose a variable oak, often referred to as Chinese cork oak. As a result, the quality of Chinese material is no longer the same as that of the Mediterranean: it is softer and less durable.

The material obtained from the bark of cork oak has a number of unique properties, for which this tree is valued so highly:

- Firstly, cork is one of the lightest solid materials: its density varies from 120 to 240 kg / m3 depending on the age of the tree and the processing method.

- Secondly, the cork is elastic: it contracts under pressure and restores its original shape after unloading.

- Thirdly, the cork has a record low thermal conductivity. In addition, it does not burn and has low water and gas permeability (as a result, it does not absorb odors).

A material with such unique properties has found many uses. But today we will talk only about one of them - flooring.

Floor cork modules are made by pressing at a high temperature small particles of processed bark (granules or chips), which are waste from other industries. No binders are added, however, like other additives.

Cork chips.

Particle agglomeration is due to suberin, which is part of the cork, which gains adhesive properties at elevated temperatures (when pressing too fine crumbs, you still have to add a certain amount of synthetic binding agents).

The quality of the final product directly depends on the size of the cork granules used.The larger they are, the higher the grade of the product, since the valuable properties of the cork in it will be better manifested.

Cork flooring is popular among consumers. It, like the starting material, has excellent elasticity and cushioning, is durable and resistant to friction, perfectly retains heat and reduces impact noise. In addition, a significant advantage of this flooring for many is its 100% environmental friendliness.

The leaders in the production of cork flooring today are Portugal and Italy. Moreover, the quality of the products of the latter is much higher, which is largely facilitated by the use of the most modern technologies by Italians. Italian cork floors are currently out of competition.

Varieties of cork flooring and selection rules

There are two types of cork flooring, which differ primarily in the way they are laid. The adhesive floor adheres firmly to the base. At the lock, individual panels are fastened to each other by means of a lock connection.

It should be noted that there is also the so-called technical cork floor, used only as a substrate for the laminate. However, we will not consider it in our review, concentrating our attention only on the finishing floor coverings.

Adhesive cork floor

Glue cork coating is a two-layer panel: the bottom layer is pressed cork chips, the top is high-quality cork veneer. Instead of veneer, other materials are sometimes used as a decorative layer - from vinyl and slate to genuine leather - but it would not be entirely correct to call such cork flooring.

1. Natural cork veneer.

2. Pressed cork chips.

Panel thickness - 4 or 6 mm. The most common sizes of sheets produced are 45x45 cm, 60x30 cm and 90x30 cm.

Glue cork floor panels are fixed to the base using contact adhesive. This flooring is not afraid of water. That is why it is recommended for laying in kitchens, bathrooms, hallways, i.e. in those rooms where there is a high probability of liquid spilling on the floor. In addition, glue cork flooring is often used in private homes with non-permanent residents, since it is not very susceptible to sudden changes in temperature and humidity.

Glue cork floor panels.

The glue cork flooring that the modern market offers us can be very different: tinted and natural color, with a bevel and without, 4mm and 6mm, with pre-varnish and without ... How not to make a mistake with the choice of cork floor? How to choose the best option for you?

Tinted cork floor or natural color?

To give preference to a cork of natural color or tinted is a matter of taste. However, so that the new cork floor does not disappoint you in the coming years, you should know a number of nuances:

- Like any other material, the cork burns out in the sun. This will be least noticeable on a light tinted coating. Non-toned cork flooring will fade the most.

- On the material of natural color, small scratches left, for example, by the claws of pets, are practically not noticeable. And it will be much easier to restore them - to sand, putty and coat with a new layer of varnish.

- In the case of tinted cork, as a rule, it is impossible to do without replacing the entire sheet. It should be borne in mind that tinted positions, unlike natural ones, can differ significantly in shade from batch to batch, so if you do not have a strategic supply of panels and you need to buy a new one to replace, be prepared for there will be a striking "patch" on the floor.

All things being equal, tinted cork panels are more expensive than natural ones.

Cork floor with or without chamfer?

Chamfer i.e.the bevel of the edge around the perimeter of the sheet serves to conceal minor irregularities in the base and thickness differences of the coating itself, as well as to visually break the floor into fragments, which gives it a relief.

Chamfered cork.

We strongly do not recommend you to purchase a tinted cork without chamfer. Aesthetically covered floor will look only if you have laid it on a perfectly flat base. Otherwise, the seams between the sheets will be striking, and the wear at the elevation will be stronger.

In addition, do not forget that the panels themselves may have slight differences in thickness, which means that careful preparation of the base is not a guarantee that your floor will look perfect in the end.

If you get panels of a natural color without a facet, then such problems will be easily solved. After laying, they can be sanded with fine emery paper, removing the tiny “steps” between the sheets and smoothing the larger ones (the border between small and large in this case will be determined by the thickness of the veneer - on average about 0.8 mm). With tinted cork, such manipulations are impossible - remove all paint with an emery cloth.

If you, despite all the above, still tend to choose a tinted cork without a bevel, then before buying at least pay attention to the color of the ends of the panels. If there is no tinting at the ends, then no matter how hard you try to level the base, do not expect the floor to look like a single canvas - each seam will still be noticeable.

Cork flooring 4 mm or 6 mm thick?

Recall that there are two standards for the thickness of sheets of manufactured floor corks - 4 mm and 6 mm. It would seem that 2 millimeters should not play a significant role, you need to take what is cheaper. However, there is a considerable difference.

- Firstly, when choosing between 4 mm and 6 mm, you should pay attention to the quality of your rough floor. The base for any cork should be flat, but for a 4 mm it should be super-level. The Six, hopefully, will hide minor flaws, while the Four will only emphasize them.

- Secondly, many valuable properties of cork in 4-graph paper are less pronounced. It is more rigid, it depreciates worse, and does not retain heat so well. In short, the sensations when walking will not be the same.

Cork flooring with or without pre-varnish?

After laying the cork floor must be varnished for 2-3 layers. The wear resistance of the flooring depends on the thickness of the lacquer layer.

Knowing this, some buyers are very surprised to see cork panels already lacquered on sale. Tinted cork sheets are usually supplied already varnished. In the case of natural color cork, both options are possible.

Why do we need factory pre-varnish, if the final stage of work will still be varnishing?

The fact is that the cork, thanks to its open pores, like a sponge absorbs any impurities. As a result, the varnish lays down on it unevenly. It’s not an easy task to varnish an unprepared cork with high-quality varnish, without stains, especially if you do not have such an experience.

In addition, after each layer of varnish applied to the cork without factory pre-varnishing, grinding is required, which will remove dust drawn by the varnish from open pores.

When buying a cork without pre-coating, be prepared also for the fact that after applying varnish on it, it will acquire a more saturated color.

Castle cork floor

No glue is needed for the installation of the castle floor, as the panels have special locking joints, like a conventional laminate. Because of these locks, which greatly simplify the installation process, this flooring is often called a cork laminate.

Castle cork floor.

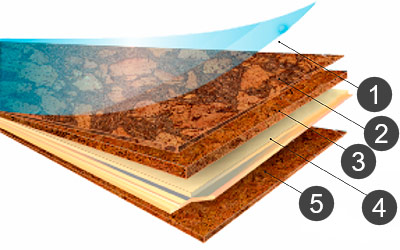

Cork laminate is already three-layer panels: the bottom layer (about 1.2 mm) is a pressed cork crumb, which in this case acts as a compensating substrate,the middle layer is high-density fiberboard (HDF), the top layer (about 1.5 mm) is cork veneer.

1. Layers of varnish.

2. Natural veneer cork.

3. Pressed cork.

4. HDF cooker with lock.

5. Pressed cork.

The thickness of the panels can vary from 7.5 to 12 mm. The size of one sheet is usually 90x30 cm

The castle cork floor, unlike the adhesive one, can only be used in dry rooms with a stable temperature and humidity. For living rooms, it will become a reliable and practical solution, but you should not think about laying it in the bathroom or in the kitchen, as well as in an unheated country house.

The service life of this floor covering, usually 7-10 years, is inversely proportional to the amount of water that enters the floor.

What to look for when buying a castle cork floor? What are the nuances to consider?

Often, the cost of lock cork panels, seemingly the same, looks different twice, or even more. Why it happens? The price of flooring directly depends on its durability and wear resistance. The latter are determined by a number of factors, including the quality of the HDF-plate, the quality and moisture resistance of the castle joints, the quality of the varnish coating.

We do not urge you to purchase exclusively the most expensive materials, but another extreme - buying the cheapest - can be fraught with unpleasant surprises. At the most budgetary positions, as a rule, the panel geometry leaves much to be desired: there are deviations of angles from 90 °, along the length / width there can be discrepancies of up to 0.5 mm.

It is simply impossible to assemble such a cork floor without cracks! “Walk” the panels and in height, i.e. there will be microsteps at the joints of the sheets, and this is a guarantee of a very quick loss of a presentable appearance by the floor. They cannot boast of cheap cork panels and the quality of the lock connection, as a result of which you may have difficulties in the installation process, but even worse, cracks will appear on the floor in the near future.

To avoid the need for an early re-repair, do not chase cheapness. Do not buy cork panels in hypermarkets - the low price of the goods presented there gives reason to think about its quality. What you find there is just an imitation of cork flooring and will not last long.

As well as adhesive cork, the lock is available in different variations - with and without chamfer, tinted and natural color, with and without lacquering.

The recommendations for choosing between the various options are not much different from those presented above, so we will repeat only briefly:

- When buying a lock plug without chamfer, be prepared for the fact that the laid floor covering will not look like a single canvas. The ends of the panels, as a rule, are not covered with color, which means that the seams, no matter how narrow they are, will be visible, and this, you will agree, is not very aesthetically pleasing.

- No matter how expensive and high-quality locking plug you choose, slight variations in the dimensions of individual panels are still possible. The consequence of this is cracks. On natural color coatings, the latter will not be so noticeable.

- You can not do without varnishing of the laid coating - varnish protects the cork from the effects of water. But the varnish will lie evenly if there is factory pre-coating on cork panels.

Comparison of adhesive and castle cork floor

Glue and castle cork flooring are fundamentally different floor coverings, and arguing that the best is absolutely pointless. How to make a choice? To make this task easier for you, we will compare glue and lock plugs for a variety of parameters.

Environmental Requirements

The glue plug has better water resistance, therefore it can be used in rooms with high humidity (kitchen, bathroom, bathroom). In addition, she is not afraid of changes in temperature and humidity, which means that it can be laid in an unheated country house.

Castle plug for damp rooms is not suitable.If the castle joints are treated with moisture resistant impregnation, the laid floor is varnished and the joints are protected, then the coating, of course, acquires a certain level of water resistance.

However, from spilled and not cleaned quickly water, which occurs, for example, during flooding, these measures will not save. The HDF-plate absorbs water and swells irreversibly, which means replacing the flooring is inevitable.

Unlike glue plugs, the lock does not like sharp fluctuations in humidity and temperature and, therefore, is not suitable for unheated rooms.

Demanding for the foundation

Glue cork is very demanding on the quality of the substrate. It should be perfectly smooth and smooth. It is not recommended to lay the adhesive cork on tiles, laminate, parquet, plywood. The ideal option is a screed, not a rough one, of course, but a finish one.

It is possible to lay on a “warm floor”, but only if its temperature does not exceed 28 ° C, otherwise gaps will appear between the cork sheets.

Castle cork is less capricious. This does not mean that the basis for it does not need to be prepared. The requirements, of course, are less stringent than under the adhesive, but it is also impossible to lay on a very curve and a tuberous rough floor - for a long time such a floor covering will not last.

As a rule, the lock plug is placed on a rough screed. Level differences of up to 2-3 mm per 2 meters of the base are allowed - the substrate will “smooth out” such irregularities. In extreme cases, it is allowed to lay on the old floor covering - tiles, linoleum, parquet.

Installation complexity

Laying the adhesive cork floor on the base is carried out using contact adhesive. Work at first glance is simple, but to lay the panels tightly, with minimal gaps, you need special skills. If you do not have such experience, we strongly recommend that you invite experts.

Laying adhesive cork.

Thermal deformation is unusual for an adhesive cork: it is dimensionally stable at moderate temperature fluctuations. This means that when laying it is not required to leave the so-called temperature seam around the perimeter of the room.

From this, in turn, it follows that you can lay without a doorstep at the border with the neighboring room, you can “come close” to the parquet, laminate, tile, you can use the narrowest skirting boards you find if you wish.

After laying on the adhesive cork floor, it is necessary to apply 2-3 layers of varnish. If we are talking about premises with increased load (in residential buildings, the hallway is primarily referred to as those), then it is recommended to increase the number of varnish layers to 4-5.

The castle cork floor is floating, i.e. it is not attached to the base. Between themselves, the cork sheets are connected, like a laminate, using a lock connection. Stacking is quick and easy, it can be done without the involvement of specialists.

Before installing the castle cork floor, a substrate is laid on the prepared base, which should smooth out the minor irregularities of the latter. As a post, a technical plug 2-4 mm thick is usually used.

Using a thicker substrate will lead to a “trampoline effect" - when you move around the room, the coating will "bounce" with you, which will increase the load on the lock joints. If you have concerns that the screed has not dried out well enough, lay a technical plastic film under the substrate, which will act as a vapor barrier.

Laying the castle cork flooring.

When laying flooring around the perimeter of the room, as well as at the border with an adjacent room or with another floor covering, around heating pipes, etc. leave a temperature gap of 10 mm wide. This means that no door sills can be dispensed with in this case, and the baseboard will have to be chosen wide - with a base of more than 10 mm, to cover the gap between the cork floor and the wall.

By the way, when planning your repair, do not forget to take into account that after laying the lock plug the floor level will rise by 12-16 mm (cork panel thickness + substrate thickness).

It is believed that the castle cork floor is ready for use immediately after installation. However, we strongly recommend that you also apply 1-2 layers of varnish on it, after filling the cracks with a special gel-sealant in the color of the cork.

The lock plug is usually supplied already varnished. However, protection requires not only a cork surface, but also seams. Do not listen to sellers' stories about the moisture resistance of the lock. The presence of a moisture-proof lock is good, but it usually does not save from spilled and not immediately removed liquid.

The best protection of the new floor from the harmful effects of moisture is a combination of a waterproof lock and full varnishing of the already laid floor covering.

Thermal insulation

Both adhesive and castle plugs have excellent thermal insulation properties. But of the two good, you can always choose the best. All things being equal, the 10 mm lock plug is warmer than the 4 mm adhesive, but colder than the 6 mm adhesive. If you have a cold apartment, then the Quartet will not save you.

To increase the temperature comfort of your home, an adhesive 4 mm cork can be laid on a “warm floor”. Its temperature, however, should not exceed 28 ° C; a further increase in the temperature of the system threatens the appearance of gaps between the cork sheets.

But to put the lock plug on the "warm floor" is impractical. It has great thermal resistance, and the heat generated cannot overcome this barrier. The result will be sad: the "warm floor" will fail, and the floor will warp.

Soundproofing

In the view of many, floor plug is a good sound insulator. However, in reality it does not protect you from extraneous sounds, since its “specialization” is shock noise. By placing the cork on the floor, you will reduce the noise from your steps (from moving furniture, from playing your child with a ball, etc.) for neighbors living on the floor below.

And in this case there is practically no difference between the glue and the lock plug - both perfectly absorb shock noises.

It should be noted that in the case when the lock plug is laid on the floor, echoing can be observed when walking. Its degree depends on the evenness of the base. An adhesive cork laid on a properly prepared base has no such effect.

Appearance

A uniform floor will look monotonous and a little boring. Chamfers could save the situation, but many potential buyers do not accept them.

Glue plug gives you the opportunity to search and find various options for decorating the floor. If you wish, you can cut the panels into fragments of various sizes and shapes, tint them and then, when laying, create various combinations of sizes, shapes, colors and textures.

Combination of glued cork flooring.

Perform artistic styling of the castle cork is not possible.

Life time

The service life of the adhesive cork floor is almost unlimited. If you follow the recommendations for care and update the varnish coating every 5-10 years, the adhesive cork will look attractive for many, many years and properly perform its functions.

The service life of the castle cork floor depends on the quality of the material, the qualifications of the craftsmen laying it, the operating conditions and an average of 7-10 years.

But if you save on material or irresponsibly approach the preparation of the base, then the castle joints will begin to break down much earlier. In addition, it must be remembered that the service life of the lock plug is greatly reduced if water is spilled on it with noticeable regularity.

Both the glue and lock plug fade over time under the influence of direct sunlight. However, this is characteristic of almost all materials, and especially natural ones.

The possibility of restoration

It happens that one or two sheets of laid cork floor for one reason or another become unusable, greatly spoiling the appearance of the floor covering or even preventing you from moving around the room. Is it possible to solve this problem with "little blood"?

If we are talking about glue cork, then replacing a hopelessly damaged cork sheet is quite realistic. Much more complicated is the case in the case of castle cork. Surely, sellers in the store will assure you that castle cork floors can be disassembled, assembled, and more than once.

In fact, this is nothing more than an advertisement that has nothing to do with reality. Practice shows that it is possible to disassemble the lock floor to the place of damage and replace the panel, but it is hardly possible to assemble it again. During operation, the lock joints swell, absorbing moisture, and deform.

Cost

The price of adhesive cork is on average lower than the price of a castle of the same class. But do you understand that your spending on cork will not end? The cost of additional materials (glue + varnish for adhesive cork or substrate + varnish for lock) is approximately the same in both cases.

But the difference in the cost of work will be significant. For the installation of glue cork flooring, craftsmen take an average of 30% more than the castle floor (if you want to save the last one, you can do it yourself).

Do not forget that before laying the cork floor, the base will need to be prepared. This will also require investments from you: payment for materials and labor of specialists is a considerable expense item. Given that the requirements for the quality of the base for laying the adhesive cork are higher, the cost of work will also be higher.

Based on the foregoing, we can conclude that the glue cork floor will cost you more than a castle.

Brief comparison of adhesive and castle cork flooring

|  | |||||||

|---|---|---|---|---|---|---|---|---|

| Adhesive cork | Castle cork | |||||||

| Environmental Requirements | can be used in rooms with high humidity | does not like sharp fluctuations in humidity and temperature | ||||||

| Demanding for the foundation | very high | high | ||||||

| Installation complexity | certain skills needed | certain skills needed | ||||||

| Thermal insulation | best performance with cork flooring 6 mm thick | at a good level | ||||||

| Soundproofing | well dampens shock noises | dampens shock noise well, but echo can be observed | ||||||

| Appearance | more decoration options | less decoration options | ||||||

| Life time | more | smaller | ||||||

| The possibility of restoration | various options are possible | the possibility of restoration is very limited | ||||||

| Cost | more expensive | cheaper | ||||||

Pros and cons of cork flooring

Now you know everything (well, or almost everything) about cork flooring. One question remained open: do you need such a floor or look at linoleum, tile, laminate, parquet? To answer it, let's try to summarize a little and figure out what are the advantages and disadvantages of cork flooring.

Pros of cork flooring

1. Warm surface

Cork oak bark consists of tiny cells filled with air. Due to this, this material has a very low thermal conductivity. This property is especially appreciated by those who choose flooring for a bedroom or children's room. Walking on a cork floor is very comfortable and pleasant, because it is warm to the touch. Moving around your room barefoot, you will enjoy the pleasant sensations.

2. Good sound insulation

The porous structure of the cork gives this material soundproofing properties. Unlike laminate or tile, cork perfectly muffles sounds. The cork floor will dampen the noise of your steps, protecting you and, most importantly, your neighbors living on the floor below. They will no longer hear the stamping of your feet, which means there will be less conflict.

3. Suitable for any room

You can choose a cork-based flooring for rooms of any purpose. Castle cork is suitable for bedrooms, children's rooms, living rooms, cabinets.

The range of application of adhesive cork is even wider: in addition to dry rooms, it also includes moderately moist ones - a bathroom, a bathroom, a kitchen. (In the kitchen, by the way, cork is especially valuable, because thanks to its elasticity, broken dishes will be much less.) And the glue cork is suitable for unheated rooms - loggias, covered balconies or country houses.

The use of adhesive cork in the kitchen.

4. High practicality

The floor is the only surface in the house that is subjected to intensive use every day, so the floor should be primarily wear-resistant. Cork is an elastic material. It is able to restore its original shape after moderate deformation - a small dent will disappear with time.

Feline and dog claws are not afraid of cork flooring - if the cork is coated with Hot Coating, it is difficult to scratch it. Cork flooring can endure a lot, but still do not hammer in nails or drop hammers on it. However, no hard flooring can cope with such stringent tests.

5. Cork comfort

Cork flooring is very good in operation. And not only because it is pleasant to walk on natural material. The cork resists slipping, so it can be stacked on stairs. In addition, cork is an elastic material, and this property helps to reduce the load on the spine when walking. If you fall, the cork cover acts as a shock absorber and will soften the blow.

6. High aesthetic qualities

Cork, like any material of natural origin, is beautiful in its nature. A certain proportion of potential buyers, however, considers the natural color of the cork to be too boring, they lack a variety of colors and textures. But manufacturers of cork floors can offer many interesting options to these buyers.

Today's market has several dozen shades in which cork flooring is tinted. And thanks to photo printing technology, a cork floor can look, for example, like an expensive parquet board, as well as shabby wood of exotic species, like concrete or dry grass. The appearance of cork coating can be almost anything!

7. Environmental friendliness

Cork is a material of natural origin, and that’s it. She cannot harm the health of the people living in the house. There is good news for the "green": despite the naturalness of the material, not a single tree was damaged during its production.

Ease of care. There are no difficulties in cleaning the room in which the cork floor is laid. A vacuum cleaner plus a damp rag - and after half an hour in your room is clean. If your floor is covered with glue, you can use a washing vacuum cleaner if you wish.

Cons of cork flooring

1. Dents from furniture and other heavy objects

Being a resilient material, cork has the ability to restore its shape. However, we are talking about a moderate and short deformation effect. Under the legs of massive furniture, dents, alas, will remain. We also do not advise you to experiment with falling heavy objects onto the cork floor or walking on it with high heels.

2. Too rough surface

Cork floors are too rough, according to some homeowners. Apparently, in their cases we are talking about a cork coated with a special varnish with ceramic chips with increased strength. If you believe the user reviews, socks when moving on this floor are wiped to holes in just a few days.

And you will not envy the knees of children crawling and playing on it. The problem can be substantially leveled by smoothing the roughness with a fine skin and then covering the floor with cork varnish. Yes, and you can walk on a deliberately warm cork floor and barefoot.

3. High price

One of the main disadvantages of cork flooring, most potential buyers call its high cost. You can’t argue here: cork really can’t be attributed to cheap materials. But everything is relative.

Cork flooring, of course, is more expensive than linoleum, but it is comparable in price with a parquet board and a quality laminate. If you do not compare the price, but the price / quality ratio, then you will not immediately say “no” by looking at the price tag in the store.