Underfloor heating under a tile: which is better to use, comparisons, advantages and disadvantages

Tile is one of the universal options for flooring, but it is often disadvantageous to stop the choice - if the tile comes with coolness in summer, walking in it barefoot in winter is at least uncomfortable, especially after taking a shower or bath. The simplest solution to the problem is to install a warm floor under the tile, but which of the best solutions on the market is suitable for this, you need to look based on individual conditions.

Content:

What type of underfloor heating is better to use for tiles

Heat sources for flooring can be hot water and electricity. In the first case, water pipes are used that are mounted in the thickness of the floor, and among the electrical devices there are heating cables, mats and film underfloor heating. Which one is better to choose a warm floor for tiles has to be decided based not only on the cost of installation and operation - much depends at least on whether it is equipped in an apartment or in a private house.

Water floor heating

Despite the large number of advantages, definitely, this option is not for an apartment. Even if you do not take into account all the difficulties with the calculations of such a system and installation, to install a water heated floor in an apartment of a multi-storey building, you will have to get so many permissions that this idea is unlikely to seem correct.

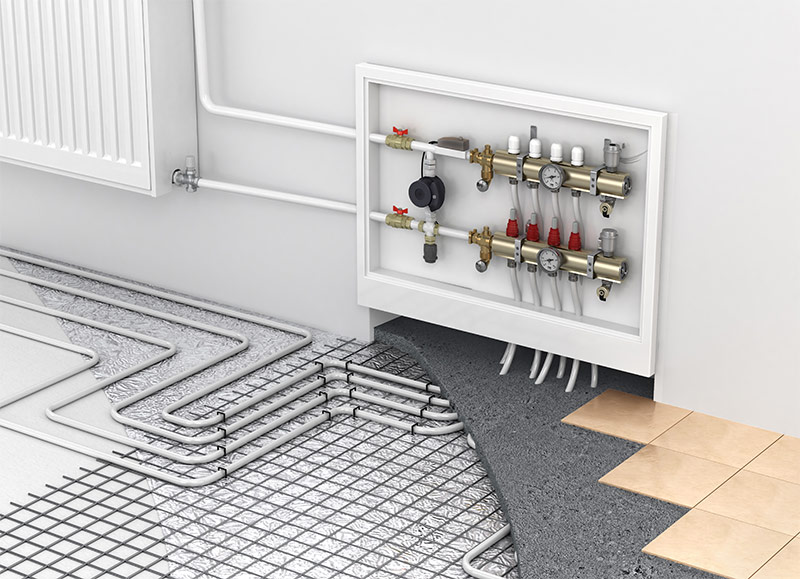

Water floor heating consists of a substrate with thermal insulation characteristics on the surface of which a pipe system is mounted, immersed in a thick screed.

The main thing to consider for installing a water floor heating:

- It is forbidden to connect it to a central heating system - if you make such a scheme in an apartment, then it should work from an autonomous boiler.

- Design and installation of a water heated floor require special knowledge - if they are not available, then, at best, self-activity will lead to large heat losses and, accordingly, to inefficient operation of the system in general.

- The whole structure requires the manufacture of a sufficiently thick screed - this is one of the reasons for the prohibition of installing it in apartments, as well as houses with weak floors.

- Large thermal inertia - there is no way to fine-tune the temperature or turn off part of the room. For example, if you install a warm floor, and then put the cabinet in one place, the surface under it will still warm up. Only the entire room can be disconnected from the heating - depending on the capabilities of the used collector.

- Water-based warm floor manifests itself best in heating large areas - if you do it for a small room, then the efficiency will leave much to be desired.

- In case of any breakdowns, you will have to break the screed for physical access to the pipes. Therefore, installing low-cost components is strongly discouraged.

- Even if an autonomous heating system is already installed in the house, the underfloor heating will put an additional load on it - if the boiler power has been selected “back to back”, it will have to be changed.

As a result, a water heated floor can be used for tiles, but it is advisable to use it in a private house with a large area and an autonomous heating system. At the same time, it is best to mount it even at the construction stage - otherwise large-scale repair work will be required, there will be a lot of dust and dirt.

Electric underfloor heating

Compared to water ones, they have a number of advantages that make these solutions preferable in the vast majority of cases:

- There is no reference to the main heating.If it is necessary to heat the tiles in the bathroom in autumn or spring, then do not heat the boiler.

- An additional screed is either not needed at all, or an ordinary leveling layer is enough, with a maximum thickness of 30 mm.

- The minimum set of necessary components that does not require additional space (the maximum is an extra switch - something like a temperature controller looks like)

- Calculation and installation is much simpler and takes an order of magnitude less time.

- More advanced settings and adjustments.

- Even if the heating wire deteriorates, then the water will not spill onto the neighbors or go into the foundation.

If these advantages are decisive, then which electric underfloor heating is better for tiles, you need to choose from the following varieties:

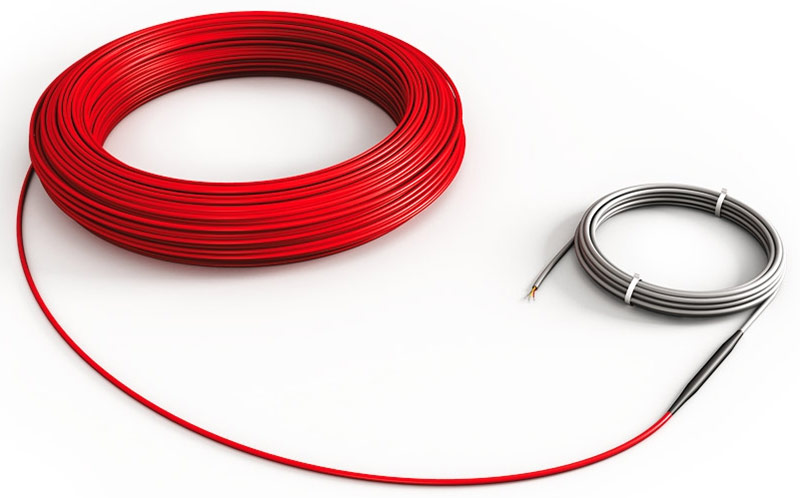

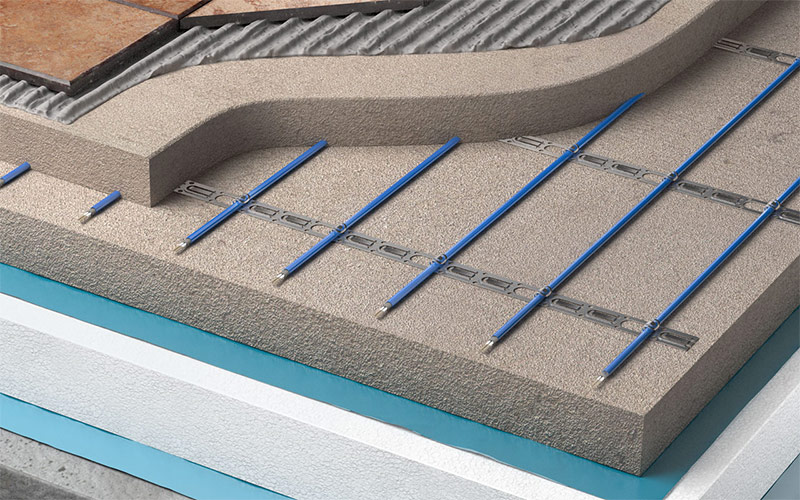

Heating cable.

This is one of the most reliable solutions when installing a warm floor. The installation principle is quite simple - a cable is laid on a prepared surface with a snake and fixed with special clips or mounting tape. By preparation is meant laying thermal insulation with a reflector (foil with cork or polypropylene) so that the heat does not go to the floor, but is transferred to the surface. Then, sensors are installed at the calculated place and you can start laying the finish coating.

The only drawback of this solution is the need for a tie at least a minimum thickness of 30-40 mm to protect the cable from mechanical damage. Some masters say that you can lay the cable directly in a layer of tile glue, but this is not recommended for two reasons:

- Any glue is much more expensive than the material with which the screed is made - this is at least an uneconomical solution.

- If over time you need to replace the tile or part of it, then when dismantling it, there is a chance of damage to the heating wire.

The heating cable is very convenient to lay - it easily bypasses all obstacles, for example, a toilet in a toilet or bathroom, but it is very likely that specialist assistance will be needed in calculating the optimal length of the wire, although this will always help in the store. However, it must be laid in a layer of cement-sand screed 30-40 mm thick, and only then on the screed, lay the tile with glue.

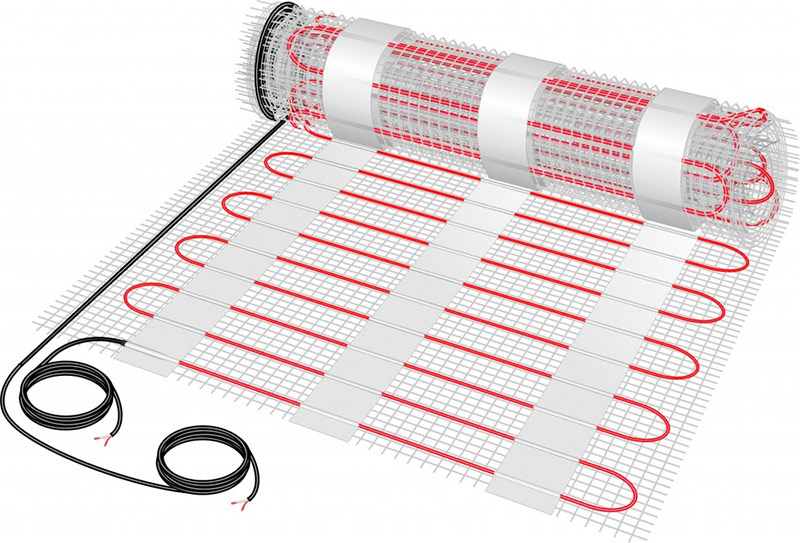

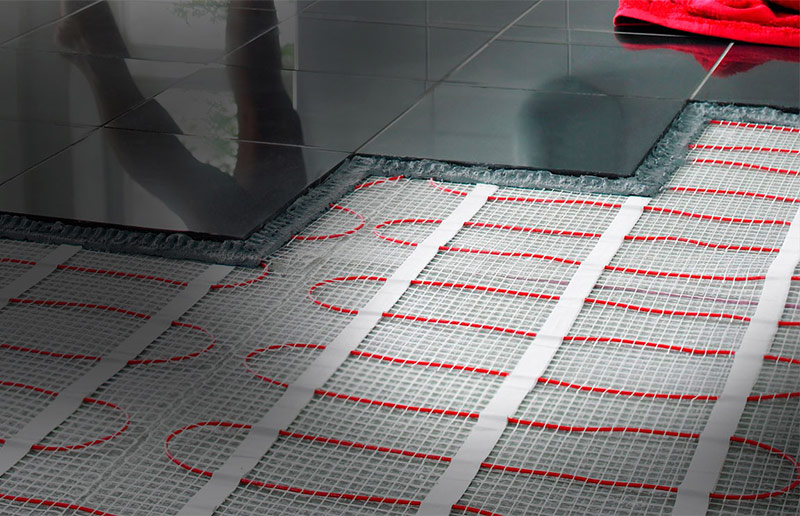

Heating mat.

In fact, this is the same heating cable, but already prepared for installation. He is still attached to the factory mounting grid, which is wound into a roll. Due to this, there is no need for additional calculations, since the power of individual thermomats is already known - it remains only to lay and connect them.

Since the cable on the thermomats is already fixed to the protective net, there is no need for an additional screed - tile adhesive can be applied directly to the mats and laid on it.

If you want to play it safe in case of tile replacement, you can fill the thermomats with a self-leveling mixture 3-4 mm thick, but manufacturers do not insist on this procedure.

A heating mat is a good solution for arranging a warm floor for tiles, because there is no need for an additional screed.

Film underfloor heating.

The second name of this heating element is an infrared warm floor, although most heaters emit most of the heat energy in this range.

Initially, such films were designed for laying under a laminate, linoleum, similar dry coatings or just under a carpet. They can also be mounted in a “wet” way under the tile, but in this case, quite a serious surface preparation is required - the installation of a rigid even base and a waterproofing layer (usually made of drywall and polymers) on top of the film.

As a result, the cost of materials and time are greater than when using cables or ready-made thermomats. Therefore, the film is unlikely to be characterized as the best heat-insulated floor for tiles, rather, on the contrary, the use of this heat-insulated floor for tiles should be abandoned.The lack of grounding also refers to the disadvantages of films - therefore, their laying in rooms where at least theoretically there may be high humidity is not allowed.

The best manufacturers of underfloor heating for tiles

There are several long-established brands on the market that offer customers high-quality products manufactured using European technologies and on equipment supplied by time-tested manufacturers. In addition to adopting foreign experience, domestic companies are actively introducing their own developments, which allows them to market competitive products at affordable prices.

Thermo

The original name of the trademark owner is Thermo Industri AB, headquartered in Stockholm. One of the production enterprises is located in Russia, the products of which are distributed by the official representative office of Thermo AB.

In Russia and the CIS countries, the trademark has been known since 1991. In the domestic market of heating appliances and equipment, she, in fact, is one of the creators of the segment of warm electric floors. The range of the assortment and its constant presence on the market are ensured by its own production facilities and a vehicle fleet, which supplies products to stores and distributors throughout Russia, the CIS and Baltic countries.

The plant produces all the necessary components to create an electric floor heating. Among the product names there are several varieties of heating cable that allows you to choose the load for rooms with different sizes and temperature conditions.

Proprietary regulators allow the most efficient use of electricity and establish the optimal mode of operation of the equipment. The heating sensors prevent overheating of the wires and allow you to control their temperature with an accuracy of one degree.

In order not to spend a lot of time counting the number of wires needed for a particular room, the company catalogs already have calculated typical options that will give a general idea of the required amount of material. Based on these data, it will not be difficult to calculate the final figures.

Thermo heating cables and mats can be used not only indoors - some of the company's products are designed to heat outdoor objects. The use of such technology will allow you not to worry about ice that can form on the steps or porch. Icing of the surface is controlled by separate sensors, so that in vain the heating will not work.

Shop offers:

Thermal Suite

If you need to choose an electric underfloor heating for tiles, then this will be one of the first brands that catches your eye. Its owner is the group of companies “Special Systems and Technologies” - a domestic manufacturer of equipment and components for installing electric heat-insulated floors. It is focused primarily on the market of Russia, Belarus, Ukraine, Kazakhstan and other CIS countries.

The production facilities of the company are located in the Moscow Region and can boast of the title of the largest European manufacturer of heating cables and the accompanying thermostatic filling, necessary for the high-quality operation of industrial and domestic heating cables.

Automated equipment for such long-established companies in this industry as Spirka, Dunst, Kuhne, Nokia and Rosendahl are used for production. It is located in workshops with a total area of almost 15 thousand m² and allows the manufacture of up to 400 different varieties of heating cables, which are of high quality and long service life even in wet rooms. This is made possible by the use of a two-wire shielding braid. To lay the cable under the tiles, the Teplolux Glims mixture is produced, which protects it from possible mechanical damage.

According to the manufacturer’s catalog, you can choose a warm floor for any size and temperature conditions of the room. If the room is small, then the Thermolux Mini model will be the best choice, and for the rooms requiring enhanced heating, the Tropix Thermolux, with increased heat dissipation. The company gives a guarantee of 20 for all its products, and the total service life is determined by the manufacturer to 50 years.

Shop offers:

National comfort

Domestic brand owned by the group of companies “Special Systems and Technologies”, with headquarters in the suburbs.

The date of foundation is considered to be 1991 - since then the production capacities of the company have expanded significantly, resulting in new complexes in Mytishchi and Ivanteyevka, equipped with modern lines for the production of cable and wire products.

The company's specialists are engaged not only in production - a significant part of the effort is directed to the design of new heating systems. Continuous work in this direction allowed engineers to accumulate unique experience in solving non-traditional problems. Often assigned tasks are carried out thanks to their own developments, which are subsequently used for mass production of heating products.

Not only the quality of the materials used determines the durability and effectiveness of all products. To create an optimal engineering solution, all developments go through several stages of production: calculation, all kinds of tests and only after that - launch into a series.

Continuous development is the key to maintaining the high quality standards set by the company. Strict quality standards and the expanding field of science-intensive research allow us to guarantee the end customer long service life of the equipment, and an extensive network of dealerships - convenient service and warranty service.

Shop offers:

The selection of goods was carried out on the basis of reviews, opinions and ratings of users posted on various resources on the Internet. All information is taken from public sources. We do not cooperate with manufacturers and trademarks and do not call for the purchase of certain products. The article is for informational purposes only.