Which construction vacuum cleaner to choose: device, types and selection criteria

Before choosing a construction vacuum cleaner, you need to figure out what tasks it is intended for. Only knowing the capabilities of this equipment and its main characteristics, you can find the most optimal option for you.

A characteristic feature of all construction sites, large industrial premises and small workshops, any places where they work with a puncher, a jigsaw or a chisel cutter, is an increased amount of dust, sawdust and other construction waste. An inconvenience for workers is perhaps the lesser of the evils generated by industrial waste. Fine dust, falling into the lungs of those who are in the workshop or at the repaired facility, can cause significant harm to their health. In addition, it often becomes the cause of failure of power tools. The only right decision to protect people's health and the operability of electrical equipment would be to purchase an industrial (construction) vacuum cleaner in this situation. It will help create comfortable working conditions, ensure safety at the workplace, and reduce the time spent on cleaning the production room.

Content:

Device, principle of operation and methods of filtering construction vacuum cleaners

Since this article is intended primarily for those who have never been a happy owner of such a technique, you should start ab ovo.

Each beginner begins by asking the question: “What is a construction vacuum cleaner and why you can’t use an ordinary household vacuum cleaner instead?” Indeed, at first glance, these two electrical appliances are no different from the size. However, having a similar device and operating principle, they are still designed to solve different problems, and this leaves its imprints in the form of a number of design features.

So, the main difference between these two varieties of the same device is the object with which to "fight". A household vacuum cleaner copes well with ordinary light household dust, but if there are small pebbles on its way, they are likely to not get into the dust collector. The situation will be even worse if someone tries to remove fine-grained construction dust with a household vacuum cleaner: a significant part of it will “spit out” itself along with the air stream. Moreover, a lot of "undigested" dust will fall into the electric motor, and this is likely to cause the latter to fail.

The industrial analogue was originally designed to collect building dust and other construction and industrial waste. And the volumes of work in question are only within his power.

Distinctive features of construction vacuum cleaners include shockproof housing, increased hose diameter, a large amount of dust collector (and, as a result of this, significant dimensions and weight of the unit itself), a highly efficient multi-stage filtration system, large engine power and its ability to work without interruption for a long time.

Device and principle of operation

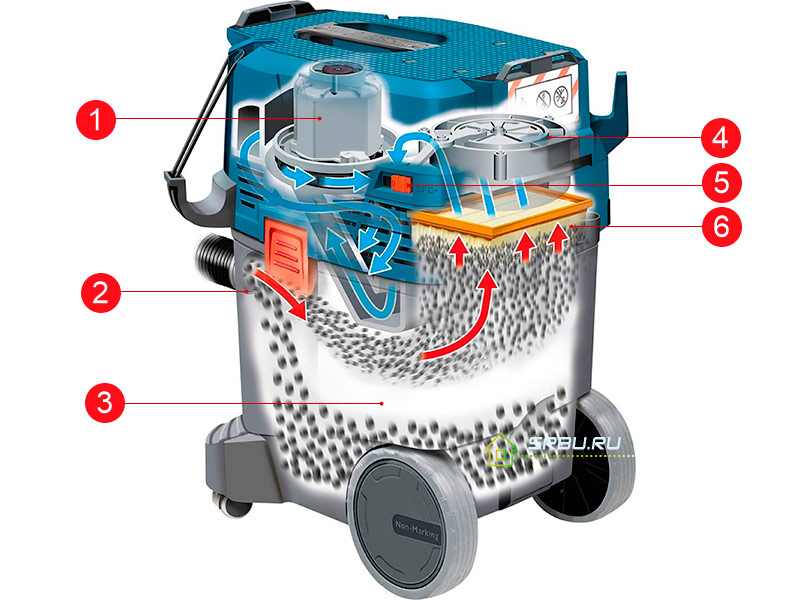

The principle of operation of the vacuum cleaner (in this case does not matter, industrial or domestic) is quite simple and well known to all of us from the school course of physics. The fan, driven by an electric motor, creates a strong vacuum inside the vacuum cleaner, which is the main driving force.Air, together with dust and other solid inclusions through the hose, rushes into this reduced pressure zone. Most of the debris that has got inside the vacuum cleaner remains inside the dust collector, the suspension of fine particles remaining in the air is captured by additional filters. After passing through a multi-stage filtration system, purified air is discharged through the outlet into the atmosphere.

Construction vacuum cleaner device using the example of BOSCH GAS 35 L SFC: 1. Electric motor with fan; 2. Incoming air stream with garbage; 3. The container for collecting garbage; 4. Filter cleaning system; 5. Switch of the filter cleaning system; 6. The filter for air purification.

A distinctive feature of construction vacuum cleaners is that dust and other contaminants can be collected both directly during operation and upon its completion (the first option, of course, is preferable):

#1. Suction from the work area. The vacuum cleaner hose is rigidly fixed as close as possible (as much as possible so as not to interfere with the work) to the workpiece. This option is far from ideal, but still allows you to reduce the concentration of dust in the air in the working area.

#2. Connect directly to the instrument. Many modern power tools are equipped with a dust extraction system - a special dust discharge pipe to which you can connect a vacuum cleaner hose. The amount of dust in the air and on the workpiece itself will be minimized. The connected hose somewhat interferes with the control of a hand-held power tool, but for the sake of comfortable working conditions, it is quite possible to put up with this small inconvenience.

#3. Cleaning at the end of work. Accumulated debris and dirt at the workplace can be removed at the end of work using a vacuum cleaner in the most traditional way.

Dust collectors and filters

As well as household vacuum cleaners, construction are divided according to the type of dust collector into bagged and bagless. The first variety can be equipped at the request of the user and in accordance with the manufacturer's recommendations both reusable (fabric) and disposable (paper) bags. The group of bagless vacuum cleaners is also heterogeneous, it is possible to distinguish two structurally different subgroups in it - cyclone (container) and water vacuum cleaners. Consider the features, advantages and disadvantages of all four types of dust collectors construction vacuum cleaners.

Fabric bags

Reusable fabric bags are best known to users, as they continue to be the most common in ordinary household vacuum cleaners. After filling such a bag with garbage and dust, it should be emptied, shaken and reinstalled. The number of cycles of using such a dust bag is quite large, and therefore this option can be attributed to low-budget. For the manufacture of reusable bags for vacuum cleaners used to be satin - a cheap and at the same time quite strong and durable material. Today, satin is practically not used for these purposes, it is replaced by synthetic fabrics. Recently, non-woven fabric has become increasingly popular as a material for the manufacture of reusable dust collectors.

We have already mentioned the main advantage of reusable fabric bags - this is a low cost in terms of one filling cycle. But they also have a significant drawback, which the future owner of a construction vacuum cleaner must be aware of. The fabric, retaining relatively large particles well, easily passes fine-grained building dust, which, with the flow of air coming out of the vacuum cleaner, scatters over long distances, uniformly covering all surfaces. However, a modern two-layer fabric based on non-woven fabric is capable of capturing even small particles several microns in size, thereby ensuring a good degree of purification.

Paper bags

Disposable paper bags in the literal sense of this layer are consumables: being filled, they, together with all the contents, are sent to a landfill. For the user, this means, on the one hand, ease of use, but on the other hand, additional expenses, and rather big ones. The cost of one paper bag for a construction vacuum cleaner is $ 5-6, and once you realize that you spent more on supplies than on the equipment itself. In addition, disposable bags, like all consumables, tend to run out, and at the most inopportune moment, and it may turn out that you will be forced to quit work and start running around stores looking for bags for your vacuum cleaner model.

However, this fly in the ointment accounts for a whole barrel of honey. Paper dust collectors have excellent performance. They significantly surpass their tissue counterparts in their ability to trap fine particles (up to 0.3 microns in size), which means that the air in the room will be clean, and you will have to clean and replace additional filters less often.

But with large construction debris you need to be careful: some coarse particles (broken glass, sharp pebbles, metal shavings) can easily tear the paper walls of the dust collector.

Dust container

In cyclone-type vacuum cleaners, all garbage is collected by centrifugal force in an integrated reservoir. The disadvantages of units of this type include increased noise level, which is the result of repeated collision of solid particles entering the tank with its walls, and limited application. The latter is expressed in the fact that “cyclones” are suitable only for collecting large particles, water and moistened debris. Many cyclone models support bag handling. When using the bag, the main filter is much less clogged.

Aquafilter

In vacuum cleaners with an aquafilter, the intake air is passed through water, where large-fraction debris settles. Smaller particles are captured in the separator following the water tank. Such a multi-stage cleaning system gives the best result. The reason why many prefer vacuum cleaners with other types of dust collectors, rather than this seemingly ideal option, is the high cost of units with a water filter. Another drawback is their inability to cope with large volumes of construction waste. In addition, it should be mentioned that the only consumable for such vacuum cleaners is water. This feature of them could be attributed to the advantages, but do not forget that in the conditions of the room where the repair is underway, large volumes of clean water are often simply inaccessible.

In addition to the dust collector, the filter system of the vacuum cleaner includes one or more fine filters of air purification. Such filters, which are disposable and reusable, are made of nylon (for fine dust), polyurethane (for suction fluid) or a number of other, usually synthetic materials. Their main function is to capture fine suspended dust of building dust, which did not linger in the main tank / bag. It is these filters that determine the quality of cleaning the room and the degree of engine wear. As well as the main dust collector, they need periodic cleaning of accumulated dirt. A filter clogged with dust is the main reason for the decrease in vacuum cleaner performance and an increase in the load on the electric motor. If you decide to save on the vacuum cleaner itself and the quality of the main dust collector, be prepared for the fact that you will have to clean and replace filters more often.

Types of construction vacuum cleaners and their purpose

Professional and household

The terms “construction” and “industrial”, related to vacuum cleaners, equally used in this article, are in fact not synonymous.All vacuum cleaners used in production and during the repair and construction work are divided into professional and domestic (the latter should not be confused with those that you use to clean the carpet at home).

They differ in the volume of the dust collector, productivity (i.e., the volume of intake air per unit time), suction force, engine life and allowable time for non-stop operation. To make a choice between a professional and a household vacuum cleaner, you just need to evaluate the intensity with which this equipment is planned to be used. If we are talking only about a few weekly hours of work somewhere in a small home workshop or about conducting repairs in the apartment on our own, then an inexpensive household option will be quite enough for you. If the vacuum cleaner is planned to be used in conditions of large-scale production, where it will have to work on a par with people, i.e. the whole shift, then you can not do without a professional model.

The difference in construction vacuum cleaners for their intended purpose

Construction vacuum cleaners are classified according to their purpose, i.e. type of pollution that they have to clean. The following varieties can be distinguished here:

#1. For dry cleaning. This is the easiest option, in fact, all vacuum cleaners cope with this function. Such units differ from ordinary home "brothers" only in power, productivity and quality of a filtration. Used to collect cement, gypsum, lime dust, etc.

#2. For dry and wet cleaning. Such devices will cope not only with dry garbage, but also with liquid spilled on the floor.

#3. Vacuum Cleaners able to collect dry dust, but nevertheless their main purpose is wet cleaning of industrial premises, places of high traffic of people, etc.

#4. For cleaning explosive and fire hazardous waste. Such vacuum cleaners are designed to collect aluminum or zinc powder, coal dust, industrial waste of organic origin (sugar, flour, wood dust, etc.). These models are equipped with electric motors without graphite brushes, which are the cause of sparking. In addition, for such units, a prerequisite is the presence of a function for measuring the air velocity. Explosive vacuum cleaners are perhaps the most expensive, but they are also used only in enterprises with a narrow focus.

#5. Heat-resistant vacuum cleaners are also highly specialized. You can meet such only at a limited circle of enterprises. As the name implies, such aggregates are used to collect hot industrial waste (for example, metal chips heated during processing).

Criteria for choosing a construction vacuum cleaner

A construction vacuum cleaner is a rather expensive tool, so it is important not to make a mistake with its choice. Focus exclusively on an affordable price and the familiar name of the manufacturer is not worth it. In order for the new unit to satisfy all your requirements and at the same time its acquisition does not result in a financial collapse for you, you should think through all the nuances in advance. Let's talk about the main parameters that you need to pay attention to.

Upcoming operating conditions

To understand which construction vacuum cleaner to choose, whether you need a professional unit or if a simpler household appliance can quite successfully cope with your tasks, do you need a narrow specialization tool, and if so, which one, try to answer a number of questions for yourself. How often is a vacuum cleaner supposed to be used? Will it be operated in a small home workshop or in a large production? Should garbage be cleaned in a dry place or on a site regularly flooded by rain? Will it be enough to just collect dust or do I need to scrub the floors to shine?

Do not forget that dust is different, and this aspect also needs to be taken into account.If the vacuum cleaner is designed to collect explosive substances, aggressive liquids or red-hot metal chips, you will have to look for a specialized model. It should be mentioned here that all contaminants are divided according to their degree of danger into several classes (and all manufacturers of vacuum cleaners must indicate what their equipment is designed for):

|

L - low degree of danger (most construction waste), when collecting these contaminants it will be enough to use a simple nylon filter, the emission into the atmosphere should not exceed 1%; |

|

M - medium hazard level (wood and concrete dust, waste from the processing of copper, nickel, manganese), it is necessary to use several filters that can catch up to 99.9% of all waste; |

|

H - high degree of danger (lead, asbestos and other carcinogens, waste with a high concentration of microorganisms (mold, fungus, viruses, bacteria), toxic chemical compounds, dust from nuclear power plants), a sophisticated filtration system and a function for measuring air flow rate are required, it is required ensuring the collection of 99.995% of waste and its dust-free disposal; |

|

ATEX - explosive and flammable waste (aluminum, coal sugar, flour dust, etc.), the use of explosion-proof equipment is required (electrical safety class not lower than IP 54). |

Power and performance

These two parameters are directly related to each other: the greater the power of the electric motor, the higher the productivity of the vacuum cleaner and, as a consequence, its resource. The power consumption of construction vacuum cleaners is 1.0-1.4 kW, which allows them to pass through themselves up to 50 liters of air per second. For professional models, the power is even higher (up to 7 kW), and this ensures a productivity of 60-100 l / s. There are vacuum cleaners (for example, Makita-449) with two motors connected in parallel: depending on the situation, you can turn on either one (and save energy), or both (and increase productivity). The greater the power, the greater the safety margin of a construction vacuum cleaner, and this is important.

Degree of depression

The vacuum created by the vacuum cleaner fan determines its suction power. For building vacuum cleaners, the value of this parameter ranges from 17 to 250 millibars. The better the vacuum, the heavier particles the vacuum cleaner can absorb. The degree of vacuum allows a better assessment of the efficiency of the vacuum cleaner than the power consumption.

Dust collector volume

The volume of a dust collector of construction vacuum cleaners, as a rule, is 20-50 liters. If the amount of garbage to be cleaned is small, do not chase a large amount of the dust bag, because an increase in this parameter will increase the dimensions and weight of the unit. But for professional models, designed to work in large-scale production, the dust collector can reach 100 liters (this allows you to avoid frequent breaks during the work shift to empty it).

Vacuum cleaner body

The case of building vacuum cleaners is made of shockproof materials - metal (aluminum, brass, stainless steel) or reinforced plastic. Often, a bumper is installed around the perimeter, which serves to prevent an accidental impact of the case against a wall or other obstacle. Given the large weight of the construction vacuum cleaners (add the weight of the collected garbage here), when choosing, you need to pay close attention to the functionality and reliability of the wheels, as well as handles for transportation. Of great importance, and you will see this during operation, the length of the power cord and the length of the hose.

Additional options

Some models of vacuum cleaners have additional functions that are not necessary, but facilitate the operation of equipment (of course, the more functional the tool, the more expensive it is).

Consider the most important:

#1. Power outlet. Power outlet on the vacuum cleaner housing for direct connection of power tools.By connecting the tool to such an outlet, the vacuum cleaner will turn on only when you have activated the tool (by pressing the button on the tool). After turning off the tool, the vacuum cleaner itself will turn off with a slight delay. This is a very convenient option, but when choosing a vacuum cleaner, look at the maximum possible power of the tool that you plan to connect to this outlet. Look at the power of those power tools that you are going to use with a vacuum cleaner and focus on the tool with the highest power when choosing a vacuum cleaner.

#2. Regulator of force of absorption. This function is not available in all models, but in some cases of using a vacuum cleaner, its presence is very convenient. If this function is available, traction can be changed, depending on the intensity of dust formation and the type of debris.

#3. Auto filter cleaning function. During use of the vacuum cleaner, the main filter element becomes clogged and must be cleaned. In order not to disassemble the vacuum cleaner every time, to clean the filter, some models are equipped with an automatic cleaning function. This system is installed above the filter and has a special valve that changes the direction of the air flow and blows through the filter while cleaning it from clogging. The system can work both in automatic mode and operate at a time when the passage of air flow has become difficult, and forced in manual mode. Such vacuum cleaners are much more expensive, but if you intend to use the vacuum cleaner intensively enough, the system is worth it.

#4. Adapters for connecting the vacuum cleaner hose to the dust extraction system of tools, as well as hose splitters that allow you to connect two or more dust generating devices at the same time.

#5. Light indication the state of the vacuum cleaner, informing the user about a clogged hose or filter, overflow of the dust bag, etc.

#6. Motor overload protection (This function is especially important for industrial vacuum cleaners operating in harsh conditions of large-scale production).

What you need to know about serviceability

Like any other equipment, construction vacuum cleaners require attention and respect. Only under this condition they will serve you for a long time and perform all their functions with high quality. Vacuum cleaner maintenance is reduced to regular cleaning / replacing the dust container and filters.

Easy maintenance of various dust collectors

Which dust collector is easier and faster to clean? Of course, a paper bag: being disposable, it is simply disposed of with the contents, and a new one is put in its place. All other dust collectors - a reusable fabric bag, a cyclone type vacuum cleaner container or a water tank with a water vacuum cleaner - require emptying and subsequent cleaning. Whether spending money on consumables or spending time cleaning reusable components depends on the operating mode of the vacuum cleaner and on your desire / ability.

Regular filter cleaning

Fine filters also require periodic cleaning. The owner of a simple vacuum cleaner will have to do this on his own: a filter clogged with dust must be removed, cleaned with a special tool, rinsed with running water and dried. Owners of more advanced models that have the function of a pneumatic shock do not need to do all these manipulations - just press a button and a powerful stream of air moving in the opposite direction will knock out all the dust from the filter. Finally, premium models with a certain periodicity themselves perform such an action, so you do not even have to think about the fact that filters need cleaning.The only question is whether you are willing to pay for it ...

Now you know how to choose an industrial vacuum cleaner. With the information received, you can easily navigate the assortment and be able to make the right choice.