How to choose a construction stapler without making a single mistake

When you need to quickly fasten a pack of paper, we are used to doing it familiar to every stationery stapler. And during repair and construction works it is convenient to use his brother more powerful - a construction stapler, otherwise, a tacker. He will quickly attach the carpet to the floor, and installation of wiring will greatly facilitate, and the furniture will help to pull. Each of these works has its own specifics, requiring the use of a tool of a certain type. Next, we will tell you how to choose the construction stapler that is most suitable for specific tasks.

Content:

What is a convenient construction stapler and what is the principle of its operation

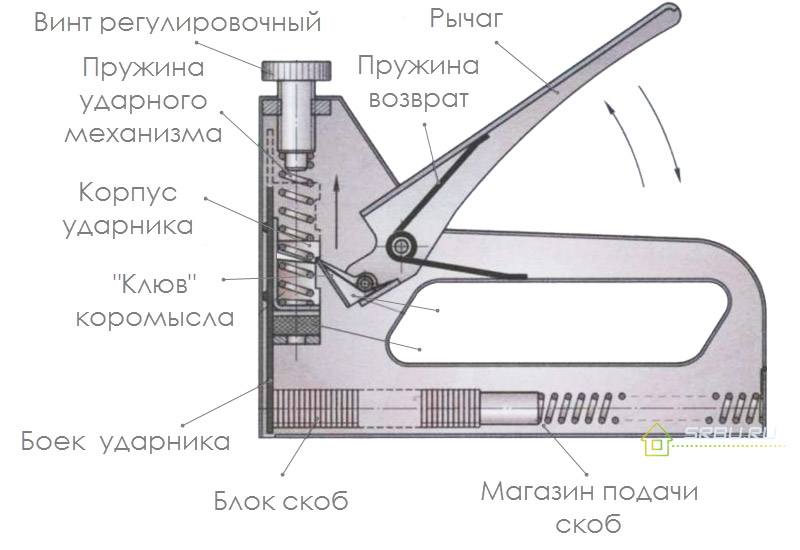

The main part of the stapler for construction work is the shock type mechanism. It is he who takes on the entire load, and for this there is a tightly compressed spring (flat spring or twisted) in it. If the stapler is mechanical, then the spring mechanism must be cocked by the force of its own muscles. In electric models, the engine does this job for you, and in pneumatic models a slightly different design (we will analyze it later, in a separate paragraph).

To bring the tacker into “combat readiness”, cock the trigger or shift the special lever to the distant position. This action allows the striker to be released, and then pull out the bracket from the pack and hammer it in the right place. When the staples run out, they need to be replenished by charging to a special store on the same principle as with a regular office stapler. But models of construction staplers are more diverse than their clerical relatives. In particular, there are those where the staples are not only clogged, but also bent due to the presence of the counterpart - the “anvil”.

The device of the construction stapler is a mechanical type.

Largely due to this design and the unique principle of operation, the construction stapler has become widely used. It's time to highlight the positive qualities of a taker for construction work:

- If, without a tacker, the old-fashioned way of working with a hammer, then it will take several times more time to work.

- Thanks to the construction of the stapler, one arm remains free during operation. This is very convenient - for example, working at height and standing on a stepladder, you can stick to it.

- There is no need to press hard on the taker. Standing on the same stepladder will help you maintain balance more easily than with a simple hand tool.

- Even after working for several hours, you will not get very tired when connecting parts and materials - after all, minimal physical effort will be required.

- Even if the nailed part is springy, the stapler, unlike a hammer, can easily cope with it.

- In uncomfortable places, where a hand crawls with difficulty, working as a taker is quite possible.

- Precise and clear impact transmission saves the surface from damage. For example, this is very important when working with glasses. The tool does not vibrate, so no scratches or chips will appear.

- Since consumables can be very diverse (staples, nails, screws), the functionality of the stapler is increased. The plus is that corrosion does not take these consumables.

- Since there are very few moving parts in the device, there is nothing to break. Therefore, the taker serves for a long time, and working with it, like maintenance, is very simple.

- All sharp-edged parts are securely hidden under the body, so you won’t cut your fingers or beat them off. And electric staplers also have fuses.

Determine the type of stapler

There are three main varieties of these tools:

- Mechanical stapler;

- Electric stapler;

- Pneumatic stapler.

Mechanical stapler - inexpensive classic

Perhaps this type of tacker is more to the liking of home masters. It has only three parts: a lever, a spring and a body in which they are enclosed. Squeezing the lever with the strength of our muscles, we cock the spring mechanism. Then, straightening, this spring clogs staples or nails.

When looking for a similar tool, choose models with a collapsible case fastened with screws rather than rivets. So you can clean the stapler if necessary, or eliminate minor problems. Look at the material of the casing - it should be strong enough. If it is made of steel, then well, there may still be an additional coating (nickel-plated, chrome-plated, powder coated). Even better when the case is made of a lightweight modern alloy.

Now a few words should be said about the percussion mechanism. If it works on an ordinary twisted spring (it is also called a torsion spring), then you will have to apply more forces, so the return will be rather big. But in a more expensive professional tool, manufacturers put a leaf (spring) spring. It is easier to work with her, and there is almost no return.

The conclusion on mechanical models can be drawn as follows: these inexpensive staplers, which everyone can afford, are well suited for small amounts of homework. But for professionals (furniture upholsters, for example) it is better to purchase a device of a different type. After all, it will not work quickly with a mechanical taker, but the hand will be pretty tired of a long effort. So for professionals, when considering how to choose a furniture stapler, they need to look towards electric or pneumatic appliances.

Electric type stapler - fast, reliable but more expensive

Such models have a significant advantage - it is very easy to work with them. A smooth press of the button activates the percussion mechanism, and no muscular effort is required. Perhaps even a child or a fragile woman can easily cope with such a device, even if it has a lot of power. Moreover, things will go much faster than when using a mechanical tool. And the materials will be able to punch harder, and combine them more reliably and firmly than in the previous case.

Only one bad luck - electrical network models have a power cord, which sometimes limits the use of a stapler. For example, insulation is placed on the roof, and the length of the wire is not enough.

However, there is a way out of this situation - a battery-powered tool. But this will make the taker more weighty, and his hands will get tired when working with him. By the way, any electric model (both battery and network) is heavier than its mechanical counterpart.

But the biggest drawback of electric staplers is their high price. Therefore, if you need the device only from time to time, think about whether it is worth spending so much money on it. In order to attach something once a year, a cheap mechanical model will do. And vice versa - if, using this tool, you earn, then definitely look at the devices equipped with an electric motor.

Pneumatic stapler - more for stationary use

A similar tool works on the force of air under pressure. He performs his task simply with lightning speed: once - and the bracket, even the longest, is already tightly clogged. But it weighs less than the electric counterpart. It would seem - what more could you want. However, there is also a catch: you will have to buy a compressor along with a stapler, heavy and dimensional. And extra money will have to be paid for him, and transferring it is quite difficult. So it’s better to buy this option for stationary work.

The choice of a construction stapler of this type is fully justified in the production environment. For example, in a furniture factory, where workers have permanent seats, neither the compressor, nor the stapler itself will have to be far removed.All operations are carried out in the same place, and pneumatics allows you to do everything quickly, and the staples will clog tightly.

Which construction stapler to choose depending on the type of tasks performed

Classic stapler

Great for home repairs. It has a mechanical percussion mechanism, triggered by pressing a lever. It is difficult to work with him for a long time - the hand gets tired. Fasteners - nails or staples of a flat type.

Cable stapler

It is necessary for fixing electric wires with diameters from 4.5 to 7.5 mm on walls, furniture or baseboards. Voltage is allowed no more than 50 volts. When installing communication equipment or laying local computer networks, they usually use such a device.

Hammer

Otherwise, a hammer-shaped stapler will come in handy where speed comes first. For example, when roofing material is laid on the roof, or the base of the floor is insulated. Here, the staples are clogged with every blow of the hammer on the material to be punched. Their fixing occurs due to inertia. True, the accuracy of such a taker is much lower than that of the previous two types. But for a heater or roofing, this is not so essential, but speed is an important factor.

Packing stapler

Needed to work with corrugated cardboard boxes. Staples hold cardboard together more reliably than scotch tape, perfectly serving as its replacement. This tool is of two types: mechanical or pneumatic.

Window stapler

It does not work with familiar brackets, but with metal studs. These are such thin nails, the length of which depends on the type of tacker. So, a mechanical device can hammer studs with a length of not more than 1.5 centimeters, an electric one - up to 2.5 centimeters, a pneumatic one - up to 5 centimeters.

Stapler for staples

This stapler has the shape of the letter "V", it is used when you need to fasten two parts at a certain angle. For example, it can be a frame for a photo or a baguette for a picture.

More on impact power

Often, this particular characteristic is crucial when you need to determine which building stapler is better. Generally speaking, the smallest impact force is in the mechanical models, then the electric ones go, and the most powerful ones are those that work on pneumatics. However, besides this, in each category there are devices that work more and less efficiently. We’ll try to figure this out.

The easiest way is to calculate the force of impact along the longest staple length that the stapler can hammer. Usually this characteristic is indicated in his technical passport. They write, for example, like this: the length of the bracket is from 4 to 14 millimeters. We should be interested in the maximum value - this is what determines the strength of the hit of a taker. Suppose that we have two models in front of us, the first of which the length of the bracket varies from 4 to 10 millimeters, and the second - from 4 to 14 millimeters. Naturally, it is better to take the second model.

It should be noted that the maximum length of the bracket to a large extent depends on the material being processed. For example, staples with a length of 14 millimeters enter soft pine wood simply perfectly, without any effort. But you have to tinker with oak or particle boards - it’s good here if you can hammer staples to a depth of 12 millimeters. So it should be remembered that with an increase in the hardness of the material, the impact force becomes somewhat weaker, and the driving depth of the consumables is less.

If you are not particularly sophisticated in such works, and you get a stapler for infrequent home use, feel free to take a model that can hammer staples long - 12 millimeters or a little more. Enough is enough for you.

A few important things

#1. When choosing a device, see if it is safe. Well-known brands keep their brand and always carefully think over this issue. The main protective function is the inability to turn on at idle. This means that the tool will only release the brackets when it is leaning against the part. But fasteners cannot fly out in the air. You never know - the hand trembles, or someone thinks of a joke, pointing at the partner turned on the tracker. Therefore, before buying, check if there is such protection.

There are other protection planes built into the device. For example, if the bracket is not completely clogged, the tool may turn off automatically.

#2. A convenient and pleasant trifle is an observation window. By the way, even many cheap Chinese takers have such a “trick”. Looking into it, you can immediately see if we have a sufficient supply of staples. Although without a window, you can feel that the stapler is somehow not working when the staples end.

#3. A convenient handle is also quite an important nuance. By the way, branded models are distinguished by the most comfortable handles - it’s even nice to hold them in your hand. And working with such a stapler is a pleasure. It is also very practical when the impact force can be adjusted. In principle, many models are equipped with such an opportunity, even simple mechanical ones.