The device and principle of operation of the dishwasher

The vast majority of our compatriots are happy to use vacuum cleaners instead of brooms, washing machines instead of basins, but at the same time they are in no hurry to delegate boring and laborious work to washing dishes with specialized household appliances. Why? Very often, the reluctance to purchase a dishwasher is due to distrust of it.

People simply doubt that this simple-looking metal cabinet can turn dirty dishes into impeccably clean and shiny. So, the time has come to get to know our home helper better, to find out how the dishwasher works, how it works, what is the function of its individual components and systems.

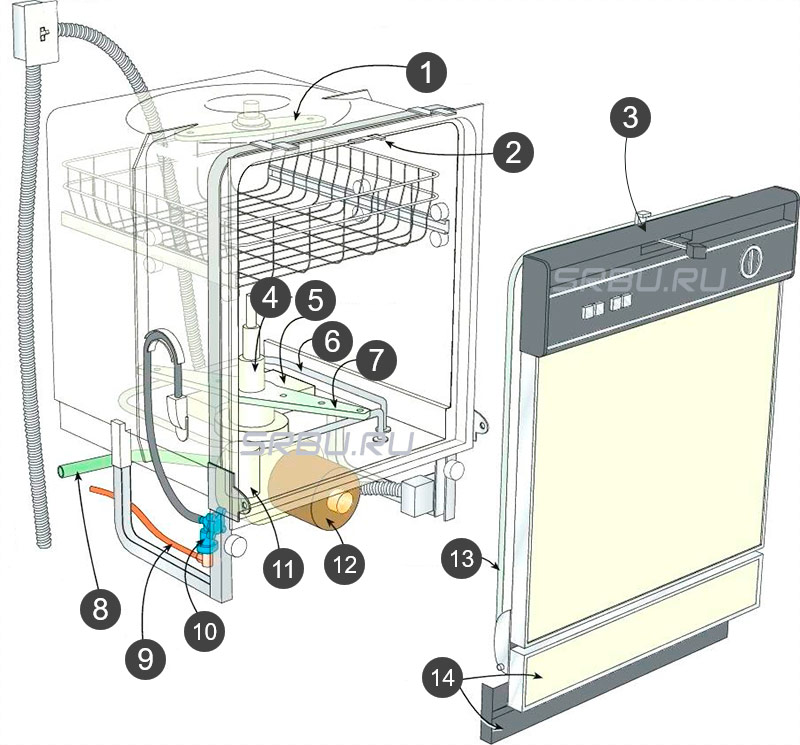

Device dishwasher

How is the dishwasher arranged? What is hidden in her "womb"? Let's open the door of the car, and with it the curtain of secrecy.

1. The upper beam.

2. Door latch.

3. Door panel with controls.

4. The axis of the rocker.

5. Water pump.

6. TEN.

7. Lower rocker arm.

8. Drain hose.

9. Water supply.

10. Solenoid valve.

11. Float switch.

12. Engine.

13. Sealant.

14. Decorative panel.

Dish baskets

Naturally, the first thing that catches your eye is the retractable trellised baskets designed to accommodate dishes. Most dishwashers have two of them, in some models a third is added to them - for cutlery. However, baskets for dishes are somewhat trivial from the point of view of the topic of today's conversation, so we will not linger on them.

Inner surface

All internal surfaces of the chamber are coated with stainless steel. The choice of this material is not accidental, because one of the main advantages of stainless steel is its resistance to aggressive chemicals, moisture and high temperatures.

Door

On the inside of the tilted front wall (door), we will see a dispenser with two compartments - there, before each washing, you will fill up the detergent and pour liquid dishwasher.

Detergent drawer.

Inside the front wall is the air duct of the drying system. The heat and sound insulation of the door is increased, because the comfort of people who are indoors during the operation of the dishwasher depends on these characteristics.

TEN

Near the bottom of the chamber of the dishwasher there is a curved tube of a heating element - an electric water heater. With its help, cold water coming from the water supply is heated to a predetermined temperature in accordance with the selected program of work.

However, in modern machines it is less and less common to see a long curved tube familiar to everyone: it is replaced by a short flowing heater, located under the bottom of the camera. The power of the heater, depending on the model of the dishwasher, can vary from 1600 to 2900 watts.

TEN of the dishwasher.

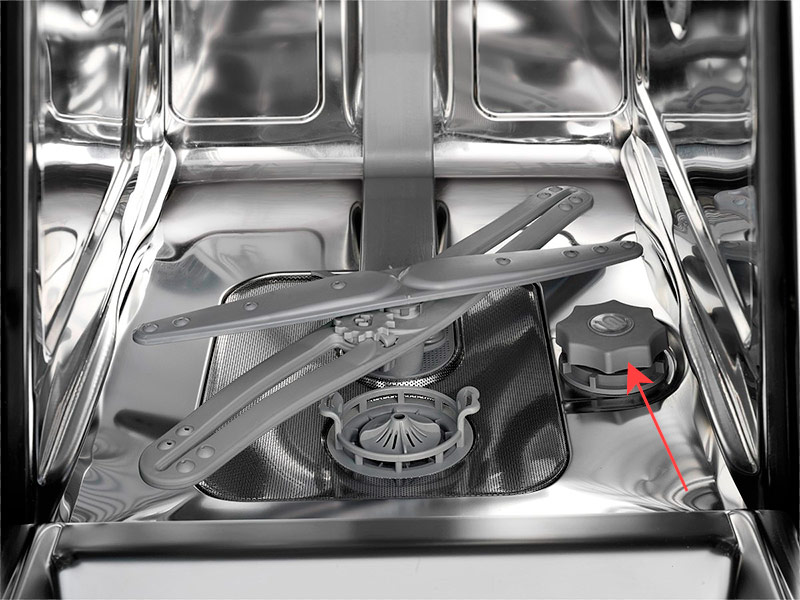

Recovery salt tank

At the bottom of the dishwasher there is also a special container for regenerating salt - one of the elements of the water softening system. The fact is that washing dishes in hard water adversely affects both the quality of the result and the condition of the machine itself: the detergent becomes ineffective, whitish stains remain on the dishes, and the heater has a thick layer of scale.

Softening of tap water is carried out by passing it through a filter filled with ion-exchange resin. The ion exchanger, after it has completed its cycle, helps to regenerate the “magic” salt, which you should regularly fill up in the compartment located at the bottom of the chamber.

Capacity for regenerating salt.

Filter system

Another “inhabitant” of the bottom of the chamber is a filter system located above the drain hole.No matter how neat you are, small pieces of food get into the machine along with dirty dishes. If you do not take measures to capture them, the drain hose, and maybe the sewer pipe, will clog very soon.

The consequences, as you know, are unpleasant. A large filter, the very first in a complex filtration system, is involved in collecting food waste that has got into the machine. Of course, it must be regularly cleaned mechanically, unless, of course, a new-fashioned self-cleaning filter is installed in your machine.

Dishwasher filter system.

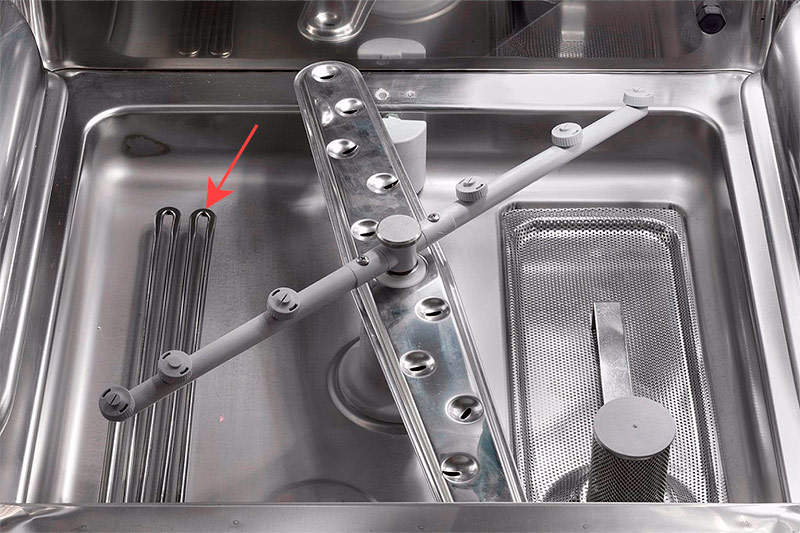

Rocker arm

The true "attraction" of the dishwasher chamber is a pair of rotating rocker arms - upper and lower. During the operation of the machine, water beats from the nozzles of each, irrigating the dishes. An electric motor is not needed to rotate the rocker arms - they are driven by a reactive force by a beating thin stream of water.

But delivering water to the rocker arm without the use of electricity is no longer possible: for these purposes, a powerful discharge pump is located under the bottom of the chamber. Water can get on the dishes not only from the nozzles of the rocker arm, but also from the overhead shower, located under the very "ceiling" of the chamber, and from the side sprinklers.

Rocker dishwasher.

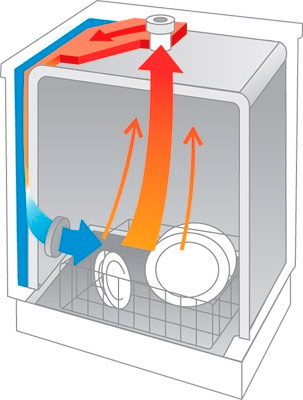

The device and varieties of the drying system

All dishes that the owner has loaded, the dishwasher must not only be thoroughly washed, but also should be dried. She can do the latter in many ways.

Turbo-drying machines.

In turbo-drying machines, the central role is assigned to a special fan that drives hot air in a closed loop.

Passing along the rows of wet dishes, the air is humidified, after which it passes through the air duct into a special plastic container called the water intake.

Leaving condensate in the intake, warm and humid air becomes cold and dry and is again chased by the fan on the dishes. Turbo dryer provides excellent results, but is the most energy-intensive.

Machines with a condensation drying system.

Most budget dishwasher models use a condensation drying system. The last rinse of the dishes in this case is done with hot water (70 ° C).

The moisture evaporated from the heated plates condenses on the colder walls of the machine and simply flows down into a special compartment, from where it is removed by a drain pump. The process is long, but does not require additional energy.

Drying with a heat exchanger can be considered as a form of condensation, but it is less static. The condensation of water vapor in this case is carried out not on the walls of the dishwasher, but on the circuit of a heat exchanger, cooled from the inside with tap water.

Air circulation, accelerating the process, is not forced, as in the case of turbo-drying, since it is carried out without the use of a fan. Air moves due to pressure differences resulting from temperature changes in different parts of the machine. Cookware in machines with a heat exchanger dries faster than with the conventional condensation method, but it consumes less electricity than with a turbo-dryer.

Leakage protection device

Perhaps the biggest nuisance that may lie in wait for dishwasher owners is water leakage. A similar state of emergency in your absence threatens with a spoiled floor covering, a long lasting odor of dampness and mold, and, most sadly, a conflict with neighbors whose apartment is located a floor below.

To prevent all this from happening, the vast majority of manufacturers equip their products with a water leakage protection system (aqua-stop or aqua-control).

The first thing you need to protect you and your neighbors from the "flood" is the timely detection of leaks. This function is performed by the float located in the metal pan of the dishwasher. This sump, located in the basement of the machine, collects water that enters here through a waterproof protective shell in case of some malfunction of the unit or damage to the inlet hose.

However, the likelihood that the hose will leak out is very small, because it has a protective shell that can withstand water pressure many times higher than the permissible pressure in the water supply. As soon as water appears in the pan, the float rises and activates the alarm system.

So, the system is notified of an emergency. Of course, this should be followed by a shutdown of the water supply. The role of the locking device is performed by a block of two solenoid valves mounted on the inlet end of the inlet hose. One of these valves - the safety valve - is always open. The second, called the worker, opens only after the device is turned on, i.e. when applying electric current to the system.

When the machine is turned off, and, accordingly, the safety valve is not energized, the operating valve is in the closed state, reliably blocking the flow of water into the hose. The pop-up float opens the contacts of the microswitch, while the supply of electricity to the electromagnetic valves is interrupted - the flow of water into the machine stops.

A leak has been detected, water has been shut off ... The car has only to start the pump-down pump, and its owner has to find the cause of the malfunctions and how to solve them.

The principle of operation of the dishwasher

What is the operating principle of the dishwasher? How do all of these mechanisms and components, when put together, make our dirty dishes clean and dry?

Stage 1. Recruitment and preparation of water

At the first stage, the dishwasher collects the required amount of tap water (usually cold, although there are models that provide for connecting to hot and cold water mains at the same time). Water is passed through a filter with an ion exchanger in order to reduce its stiffness, mixed with a detergent that you previously poured into a special container, and is heated to a temperature determined by a given program.

Stage 2. Spraying the working solution under pressure

The pre-prepared working solution is supplied under pressure to the sprinklers - the upper and lower rocker arms, and, if this is also provided for by the design, to the sprinklers built into the upper and side walls of the chamber. The reactive power of the fine jets of water beating from the nozzles causes the rocker arms to rotate, so that the solution of the detergent in hot water is in every corner of the dishwasher chamber, in every slot in the rows of dishes placed there.

Powerful jets moisten the surfaces of dirty dishes, softening the dried-on food residues and knocking them down, and drain to the bottom. The contaminated liquid is cleaned by passing through a filter system and is again fed to the sprayers. This is repeated until the wash time set by the program ends. Dirty water is drained into the sewer, and a portion of fresh is collected in the car.

Stage 3. Rinse

Then a liquid rinse aid is added to the water - a multi-stage process of removing detergent residues from the dishes begins.

Stage 4. Drying

The dishes are clean, but that's not all - the last stage is ahead. The technique will bring the job to the end, eliminating the need to wipe the plates. There are several drying methods, the most common of them are condensation and turbo drying. In the first case, the moisture itself evaporates from the surface of the dishes heated during washing and condenses on the colder walls of the chamber or on the heat exchanger circuit, the condensate flows down and is pumped into the sewer.

In the second case, dishes with a fan are blown with heated, dry air.

The entire cycle, depending on the selected program, lasts from 25 to 160 minutes. After the end of the process, you will have to wait a little longer before you get the dishes out of the car, because you still need to cool down with freshly washed plates and glasses.