Acrylic bathtubs pros and cons - put all the dots on the "And"

The purpose of the information discussed here is not to promote certain products, but to try to give objective advice to potential owners of new plumbing. We will examine further what an acrylic bath is, find out its pros and cons, take a look and make the right conclusions.

Content:

How do acrylic bathtubs

Baths, commonly referred to as acrylic, are actually composite products of a layered structure, made from several materials. The surface in contact with water and skin is made of acrylic - originally transparent plastic. Color is imparted to it by special powders added to liquid polymethyl methacrylate (PMMA) before the polymerization stage. The composition of sanitary acrylic includes additives that prevent the growth of harmful bacteria on the walls of the bath, as well as other components, thanks to which the plastic acquires valuable qualities:

- Plasticity - the material is well formed under the influence of high temperature;

- Color fastness - acrylic products do not fade;

- Hygiene - due to the low porosity of the plastic, the dirt does not linger on its surface;

- Maintainability - minor defects are easily restored.

In the manufacture of bathtubs, sheets of material are used that differ in thickness, size and manufacturing technology used:

1. Material. “Pure” acrylic (injection-molded) is made by pouring the compound into hermetic forms between two glasses and subsequent polymerization in a steam oven. The result is a solid and wear-resistant high quality sheet material.

2. Material. Two-layer plastic (coextruded acrylic) is produced by simultaneously extruding and combining the PMMA melts and another polymer - acrylonitrile butadiene styrene (ABS). After hardening, the plastic structure has a glossy surface on one side and an impact resistant base on the other.

Acrylic baths made from these components have advantages and disadvantages, which differ significantly due to the different characteristics of the materials.

High-quality plumbing fixtures are made from "pure" acrylic. In the manufacture of the bath from this material, the plastic sheet turns into a bath, passing sequentially through four operations:

1. Forming - a sheet with a thickness of up to 8 mm is heated and stretched using vacuum to the size of the workpiece;

2. Reinforcement - the reverse side of a thin acrylic shell is covered with a composite layer (usually polyester resin mixed with fiberglass);

3. Trimming - excess plastic is removed, the required holes are drilled;

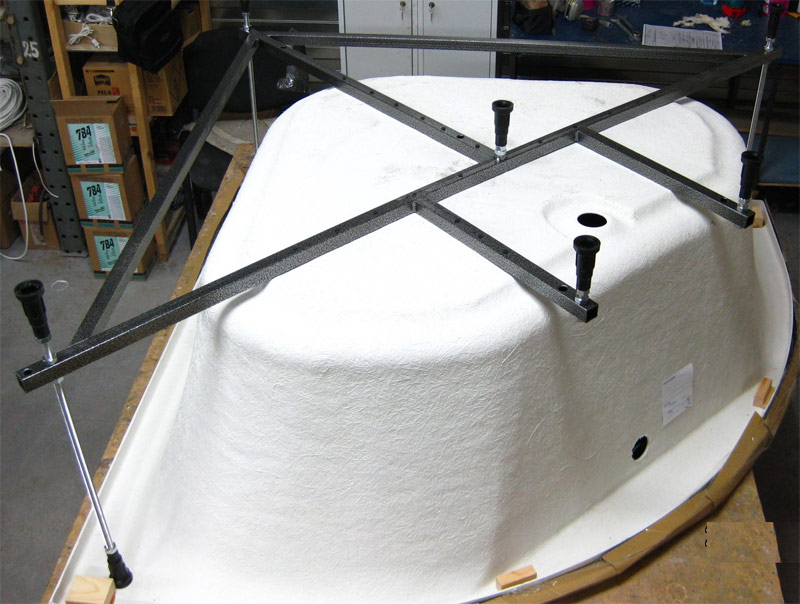

4. Assembly - the workpiece is mounted on the power frame and polished.

Without the use of a power frame, an acrylic bathtub will not support the weight of a person.

The method of manufacturing a bath from a two-component sheet is simpler, its cost is lower. But in the end, the operational parameters of such an acrylic bath are much worse: there are low indicators of coating hardness and reliability of the entire structure. Two-layer plastic is used in inexpensive products.

What are the advantages of acrylic bathtubs?

+ Light weight.

The mass of the acrylic bath does not exceed 40 kg, therefore it is easily tolerated, does not create a load on the inside of the house floors.

+ Sufficient strength.

Products made by casting technology withstand strong impacts with minimal damage.

+ Good heat capacity.

The collected water retains its initial temperature for a long time (up to an hour).

+ Variety of shapes.

Corner, oval, rectangular or with curving lines - a plastic bathtub can be selected for any interior.

+ High sound insulation.

The polymer structure absorbs the noise of the water being poured well.

+ Comfortable feeling.

Acrylic surfaces are smooth, but non-slip and pleasant to the body.

+ Variety of colors.

It is not at all necessary to purchase snow-white plumbing, and having bought a bath of any shade, you can not be afraid that it will fade.

+ Easy care.

For cleaning the walls do not need special chemicals, just a simple soap solution.

+ The possibility of restoration.

Chips, scratches and cracks are repaired with polishes and repair compounds right on the spot.

+ Wide functionality.

Acrylic bathtubs can be equipped with all kinds of options: aero- and hydromassage, automatic overflow and others.

A significant part of the listed advantages relates exclusively to first-class products from molded acrylic - their service life is 10–25 years. Bathtubs with thin walls made of ABS were originally designed for short-term operation - about 3-4 years.

Acrylic bathtub - each material has cons

- Sensitivity to alcohol and powder products.

Washing an acrylic bath requires a deliberate attitude to avoid surface damage and premature repair. For cleaning, do not use compounds containing aggressive chemicals and abrasive particles.

- Mechanical fragility.

A bath under heavy weight can bend and “play”, which can cause some discomfort. If heavy objects fall, the likelihood of cracks or holes forming is high. Major damage is not always amenable to restoration, sometimes a bath is easier to replace.

- Insufficient resistance to high temperature.

The plastic melts at 160 ° C, therefore, under the influence of excessively hot liquid, the acrylic bathtub becomes softer and capable of deformation. For this reason, it is recommended to pour cold and then hot water first.

- Acrylic plumbing costs are higher than steel and cast iron counterparts.

Given the limited service life, the purchase of a bathtub of this type is hardly a justifiable financial investment.

Acrylic Bath Tips

1. Decide on the dimensions of the free space of your bathroom;

2. Grab a flashlight in the store - it will be easier to identify thin spots on the sides of the bathtub with it;

3. Press on a surface of a bathtub - you can feel reliability of a design;

4. Check the cut of the product - there should be two layers: acrylic and resin;

5. Swipe your hand on the surface - roughness indicates poor quality of the goods;

6. Pay attention to the form - a robust bathtub is not too complicated;

7. Ask the consultant for the technical specifications of the selected sample.

Remember the direct relationship between the cost of an acrylic bath and the thickness of its walls. For expensive and high-quality specimens, the thickness of the sides is 4–6 mm, and budget and low-grade products have walls of 2–4 mm.

A simple acrylic bathtub costs at least 6,000-1,000,000 rubles (Bach, Eago, Victoria), equipment with additional equipment raises the cost for 20,000 rubles. And above 60,000 rubles, a luxurious product with an antibacterial coating, thickened walls and chrome handrails from a European manufacturer (Teuco, Villeroy & Boch, Jacob Delafon) will cost.

The materials traditionally used for plumbing fixtures also have their drawbacks. Are the negative qualities of acrylic bathtubs significant disadvantages or are they just features that need to be accepted and enjoy the benefits - this issue is addressed individually.