Top Mattress Manufacturers - Marketing Tricks and Tricks Against Fair Compliance with Norms and Technologies

In this article, we will tell you how to recognize the marketing steps and tricks of mattress manufacturers in order to ultimately choose a really high quality product at an affordable price. We analyzed a large number of manufacturers, technical specifications, as well as user reviews and compiled a rating of mattress manufacturers, which can be found below.

Content:

What you need to know about the production of mattresses

A good mattress should have excellent orthopedic properties. The mattress filler should consist of natural materials, at least in part (if substitutes are in the design, they must certainly be of the highest quality). The price should correspond to the quality of the product (reliable design, high-quality assembly).

It is possible to obtain a product with such characteristics provided that the established production standards are observed. Unfortunately, each manufacturer has its own understanding of production standards and its product categories in price lists.

Not all manufacturers are able to “keep the brand”: many go to all sorts of tricks to help reduce costs and increase the price of the finished product. In addition, the competition led to the competition "who is better": manufacturers are trying to give the product new attractive characteristics (some of them absolutely do not affect the quality of the mattress), increasing prices.

To distinguish a truly high-quality product from the result of “creative research” by unscrupulous manufacturers, we consider the subtleties of the process and the popular tricks of manufacturers.

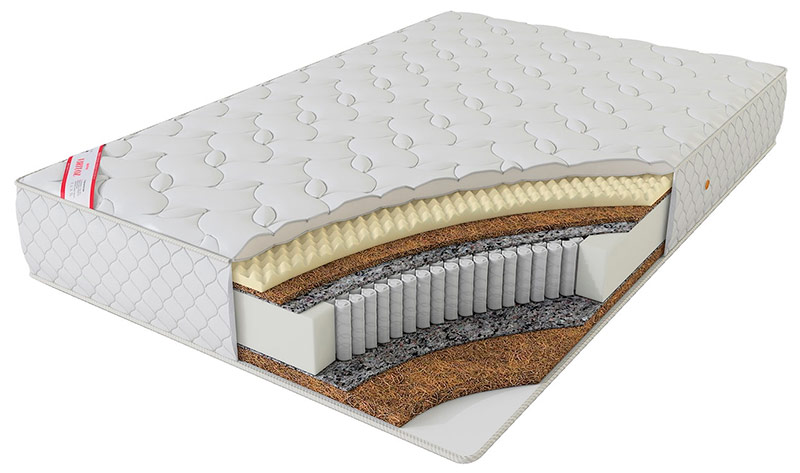

Mattress filler

It should be?

Ideally, natural latex and coconut fiber (coconut coir) should be used as filler. They give the mattress softness and anatomy.

When using foam rubber and sintepon, only the highest quality materials with sufficient technical characteristics should be used.

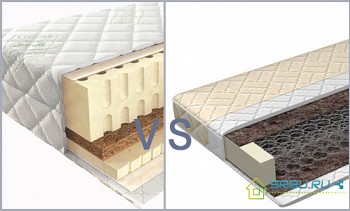

Materials used as filler for the mattress, from top to bottom: foam rubber, coconut coir, latex, synthetic winterizer, felt.

How is cost reduced?

Instead of natural fillers, polyurethane foam (PPU or, more simply, foam rubber) is used. And in order not to state this openly, they call it artificial latex. But it is good if it is high-quality foam rubber with sufficient density. Sometimes foam rubber with a density of less than 25 kg / m is used.3. In this case, the mattress will have a normal appearance and at first you will not even notice that a filler with low characteristics is used. The difference will begin to be felt after 3 to 6 months after operation, when the foam rubber loses elasticity.

The result of using low density foam rubber.

Sometimes manufacturers say that the mattress has a natural filler (coconut or latex), although it is only a thin layer (up to 10 mm), and the rest (10-20 mm) is foam instead of latex or felt instead of coconut coir.

Replacing foam rubber and synthetic winterizer with batting provides even greater savings. The batting filler practically does not spring and very quickly begins to tuberize.

How to check?

Clarify what material is used as a filler - natural or artificial. Does the thickness of the layers comply with the established standards. Be wary of the product on the packaging of which the thickness of the layers is not indicated.

Unfortunately, the difference between a mattress with a high-quality filler and created from low-quality components can not immediately be noticed right away. Pay attention to the price.You should not consider too cheap options, but look for a decent one among goods with reasonable prices. Or among the most expensive, if you want to get a mattress from a natural filler.

Spring unit

It should be?

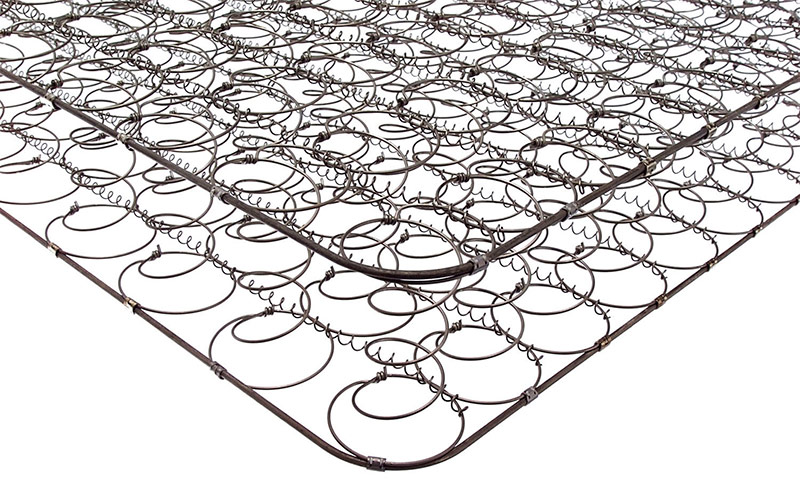

The quality of the spring block from which the mattress is made depends on whether it will have an orthopedic effect. The spring block of the mattress can be dependent when all the springs are combined into one block (Bonnel block) or independent, where each spring is sewn into a separate cover and does not affect the neighboring ones.

If we talk about the dependent spring unit, then it is correct to use the frame unit and five-turn springs from a sufficiently thick wire.

Bonnel frame spring block.

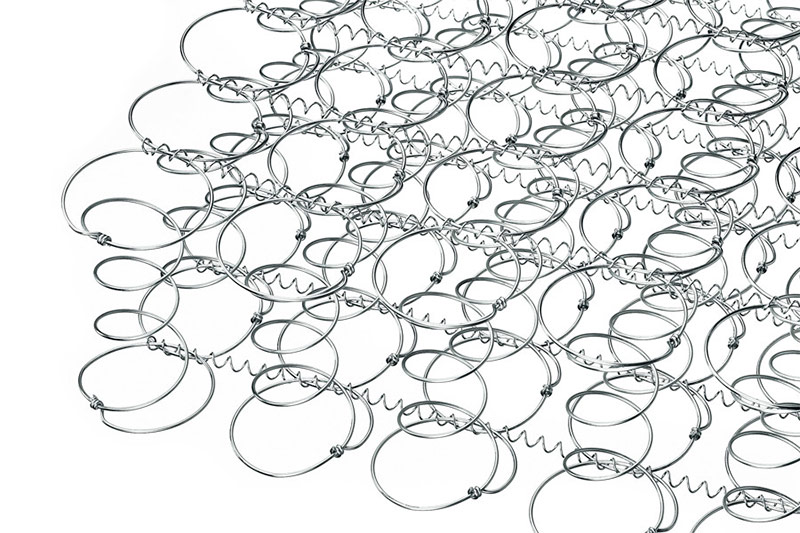

Five-coil spring.

The independent spring unit must have a sufficient number of springs. The optimal density of the springs - 256 pieces per 1m2.

256 independent spring unit with spring density on 1 m2.

How is cost reduced?

To reduce the cost of the dependent spring unit, some manufacturers make it without a frame, saving up to 10%.

Frameless spring unit.

The use of four-coil, instead of springs with 5 turns, also reduces costs. As a result, the quality of the final product deteriorates significantly - the mattress will not be sufficiently elastic.

Four-coil spring.

You can save on an independent spring unit by reducing the number of springs by 1m2. Some manufacturers who comply with this rule resort to self-praise: they call this design improved and attribute merit to themselves, although in fact it is only a matter of observing the rules. But this is not the worst (some exaggeration in advertising is permissible). It is much worse if the manufacturer inflates the price for such an “improvement” (here we can safely speak of the manufacturer’s dishonest behavior).

How to check?

If the mattress is made using the Bonnel block, click on the edge of the mattress, if the block is frame, it will spring well, it will be elastic. If the "correct" springs are taken, the thickness of the mattress will be at least 17-22 cm. In this case, it is necessary to find out due to what this thickness is gained. Since when using four-coil springs, some manufacturers select the thickness using an internal filler. To check, squeeze the mattress on both sides until the spring block begins to compress and measure the resulting thickness. If the mattress is of high quality, this distance should be 14 - 15 cm.

If the mattress is made of an independent spring unit, try to sit on it and lie down on it. The mattress should adapt to the body of a person and keep it on weight. You should not feel dips and hardnesses.

The work of a high-quality independent spring unit.

If it is not possible to lie on the mattress, place the mattress vertically against the wall at an angle. If the density standards were met, the mattress will retain its shape, will not bend much under its own weight.

Upholstery

It should be?

As upholstery fabric use high-quality knitwear, non-woven material, silk, jacquard (with a ratio of natural fibers and synthetics 70/30).

Whatever the coating, it must be quilted. The quality of the stitches affects the performance of the mattress.

How is cost reduced?

On the market you can find mattresses coated with a material with jacquard weaving, which does not differ in strength (comparable to the strength of nonwoven materials) and performance (stretched, rubbed, torn). In appearance, it is no different from high-quality fabric. Other low-quality fabrics that are highly electrified are also used.

Non-quilted mattresses can not withstand loads, the coating creeps, the product loses not only the appearance, but the integrity of the structure.

How to check?

Find out which upholstery material the manufacturer used, clarify its composition if possible.You can try rubbing the fabric or stretching it a bit, very poor quality material will immediately become "electric shock", nap.

The quality of the stitches can be determined by looking: the pattern is small (in the form of a square, each side of which is no more than 20 cm), without missing stitches.

Quality mattress stitch.

Additions

Sometimes a nice bonus is included in the package - a removable cover. There are models with dubious additions.

For example, the valves on the sides of the mattress, which are presented as a necessary structural element for ventilation. In fact, the presence of holes is just a marketing ploy (the mattress is well ventilated without them) and a part that is completely unnecessary in the mattress (cling to the edges of the bed and scratch it). The product is sold at an inflated price, although the cost of such an item is not more than 2.5 rubles per piece.

Misleading is the main method of unscrupulous manufacturers. Be vigilant and do not let yourself be deceived.

What you need to know about mattress manufacturers: experience against agility

Many people are capable of producing mattresses: the market is filled with goods from a wide variety of manufacturers. New buyers and companies with many years of experience, large and small enterprises are fighting for buyers. This type of business turned out to be affordable and profitable (production volumes are growing annually), but at the same time it is very competitive.

It is not always prudent to give preference to “seasoned” market players. Young companies have strong motivation (their goal is to find and retain first customers, make themselves known), but at the same time they do not bear such serious costs as large manufacturers (on advertising campaigns, on the salary of expensive employees who are not directly involved in the manufacturing of mattresses - lawyers, logisticians, marketers and others).

Newcomers to the market, unlike enterprises with many years of experience, can afford to set low prices for goods that are similar in quality to the products of large enterprises. Therefore, remember, an unknown brand is not a reason to abandon its products. The main thing is the quality of the product. And how to judge the quality, by what indicators, we examined above.

Top mattress manufacturers

Which company mattress is better to choose? Of course, one that complies with production standards, and if it offers the buyer lower-quality goods, then only at the appropriate price. The products of the companies listed below are of high quality, the best characteristics, created from raw materials of almost the same responsible suppliers.

Ormatek

Ormatek company is one of the market leaders, as it occupies a market share of at least 20%. The company’s “arsenal” has 5 production sites. According to representatives of the company, more than 3.5 million Russians are already sleeping on the mattresses of this company.

The company specializes in the production of single and double sleeping mattresses for adults, but also produces mattresses for children and adolescents.

On sale are both spring and springless mattresses Ormatek. Among the models with a spring block there are independent and cheaper ones with a Bonnel block. Springless are filled with PUF, latex and latex-soaked coconut coir. Such a variety of models allows the company to provide one of the largest assortments.

Models with different degrees of rigidity (low, medium, high) are provided. The last interesting innovation is double mattresses for two with different body weights. More than 400 models of different sizes, colors and characteristics are produced.

Vegas

Country of production - Belarus. Vegas company uses in its production modern equipment and imported components, raw materials (coir from the Netherlands, latex blocks from Belgium). The quality of the products is confirmed by certificates from Belarusian, Russian and European laboratories. At the production site, finished products are always subjected to quality checks.

The assortment of mattresses with different levels of rigidity - from the softest to the most rigid.Products are manufactured by a spring block (including inexpensive models with dependent springs) and springless (natural latex, polyurethane foam is used as a filler), which withstand heavy loads and retain elasticity until the end of the service life specified by the manufacturer.

Ascona

The brand belongs to Hilding Anders Holding - it is the leader in the European market and the largest enterprise producing sleep products (30 enterprises in 20 countries, one of which is Askona plant.

The products are created using advanced technologies, meet the highest standards, and are subject to the strictest control of the specialists of the holding's own laboratory (the laboratory is certified according to the ECO standard). The quality of mattresses is confirmed by awards for high performance properties - “Brand No. 1”.

As a filler, latex, coconut fiber, memory foam (with a memory effect) are used.

By optimizing production, the manufacturer was able to reduce the cost of products and make them available to customers with different income levels. The products are delivered to chain hotels, sold at retail (every third resident of Europe is the owner of the Hilding Anders product).

Consul

Consul is the largest holding company that originated 80 years ago. The quality of the mattresses of this manufacturer is confirmed by international certificates, meets the Ocko-Tex Standard 100 (environmental safety and health).

The brand is so promoted that the manufacturer allows himself to make an extra charge of up to 30-50%. Of the shortcomings, users most often note constantly “moving out” removable covers that are not able to keep their shape.

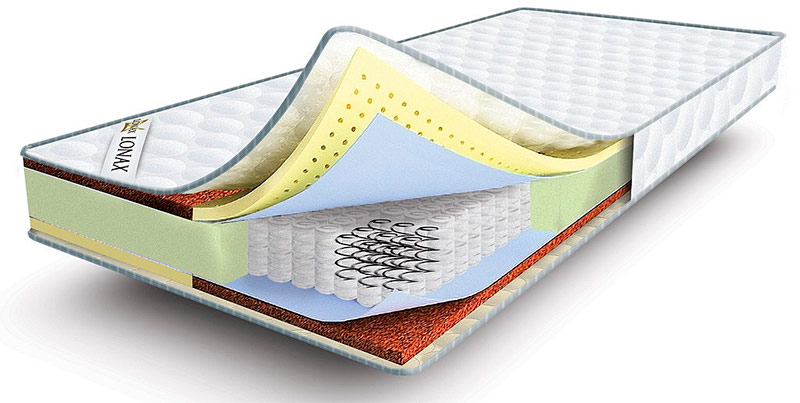

Lonax

Over the 6 years of its existence, this company has been able to break out into the leaders in the market of products for sleeping, because its products are of high quality and affordable prices. Products are certified in state bodies of the Russian Federation and the European Union.

The factory has many structural units that provide a complete cycle for creating mattresses (from model development to shipping to the consumer), including a research center where prototypes are developed and tested. Lonax mattresses are made on modern German machines, using natural materials (latex, coconut coir). The suppliers of the company are well-known European manufacturers.

The factory produces spring with independent blocks and springless mattresses. The assortment has mattresses round in shape and children's models. The cost of models is available for each buyer.

When developing models, the manufacturer focuses on the wishes of users and on the results of their own research. This approach guarantees the creation of a safe product with high performance.

Virtuoso

Another young manufacturing company that has become famous thanks to the high-quality materials used, well-thought-out products with orthopedic and anatomical effects.

Virtuoz mattresses are produced on professional equipment - these are automatic cutting machines Kuris (Germany), sewing machines Juki (Japan), edging machines of the famous brand - Singer (USA). In addition to high-quality equipment, the company has a creative approach to creating new models. With each new idea, more and more comfortable products for sleeping are obtained.

Today the company is ready to offer a variety of models: from inexpensive springless and spring mattresses with a Bonnel block to prestigious orthopedic mattresses, with an independent block and natural filling.

Materlux

Italian company founded in 1945. Mattresses of this company are sold today around the world under the brand of the same name. MaterLux is a recognized leader in the industry, millions of people use this product.

Modern production lines, the latest equipment and software, quality control at each stage of production are carried out by employees of a specially created unit.

Toris

It has been producing mattresses for 20 years and has been one of the market leaders since 2002.The work of the company was awarded with a diploma for its contribution to the development of the market, and the quality of mattresses was awarded with an award from the Consumer Rights Fund and certificates of honor. The company is equipped with modern equipment, which allows us to produce high-quality mattresses.

The company produces double mattresses with independent spring blocks of different stiffness (patented development) for couples with a significant difference in weight. As well as many other models with orthopedic effect, which are convenient and comfortable to sleep on.

There are also mattresses in the assortment with dependent spring blocks and a filler made of porous latex or polyurethane foam.

Rollmatratze

New to business, but very successful. Like large, experienced competitors, it adheres to the “success formula" in production: a wide range, high quality materials, their safety for health, modern technologies and high-quality equipment, affordable cost, but not reduced due to the quality of the components).

Partly successful entry into the company’s market was ensured by cooperation with the well-known German company Fillmatic: colleagues from Germany share their young experience. Products are certified by Russian and international experts.